Water Vapor Barrier Testers for Barrier Materials

Product Details:

- Mounting Type Benchtop

- Port Size 6 mm, quick connect fitting

- Application Testing barrier materials, films, packaging, and laminates

- Automation Grade Fully Automatic

- Number of Specimens 3 (simultaneous testing)

- Temperature 15C to 55C (programmable)

- Operating Voltage AC 220V

- Click to View more

Water Vapor Barrier Testers for Barrier Materials Price And Quantity

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

Water Vapor Barrier Testers for Barrier Materials Product Specifications

- Digital LCD Touch Display

- RS232, USB

- Leak detection, real-time monitoring, automatic calibration

- Microcomputer-controlled, touch screen interface

- 0.01-10,000 g/m24h

- Programmable, up to 150 mm/min

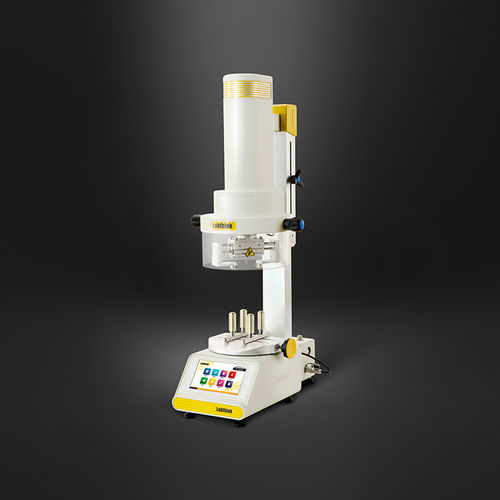

- Water Vapor Barrier Tester

- 50 Hz

- Laboratory and quality control

- 0.6 MPa

- 20%-90% RH (adjustable)

- 0.01 g/m24h

- 115 mm diameter

- 0.001 g/m24h

- Benchtop

- High throughput (up to 100 tests/day)

- Testing barrier materials, films, packaging, and laminates

- 250 mm

- 6 mm, quick connect fitting

- Fully Automatic

- 50 mm, 75 mm, 100 mm (customizable)

- 3 (simultaneous testing)

- AC 220V

- 15C to 55C (programmable)

- AC 220V, 50Hz

- Industrial grade

- 62 kg

- 10 seconds

- 400 mm

- 0.01-10,000 g/m24h

Product Description

Product Features

Professional

This instrument is based on the cup method, and is professionally applicable to the water vapor transmission rate test of film specimens. It is equipped with high resolution sensor, whose test resolution is 0.0001g. The sensor also provides excellent test sensitivity.

- Both water method and desiccant method can be used

- Wide range and high-precision of automatic temperature and humidity control to support various combinations of non-standard test conditions

- Standard air velocity enables constant humidity difference between two sides of test dishes

- Automatic reset before weighing ensures accurate weighing data

- Gas cylinder lifting structure design and periodically weighing method to reduce system errors

- Convenient fast-access calibration ports for temperature and humidity

- Reference film or standard weight for fast and accurate calibration

High Efficiency

W3/062 system adopts the precision design of round dish rack which is equipped with 6 test dishes and supports 6 different specimens to test individually at one operation. It can be also connected with 9 satellite bases together to accomplish up to 60 tests at the same time.

- Precision design with high test efficiency and ultra-high system accuracy

- 6 distinct or equivalent specimens can be tested individually with independent test results at one operation

- The system can be easily connected to a maximum of 10 instruments to accomplish up to 60 tests at the same time

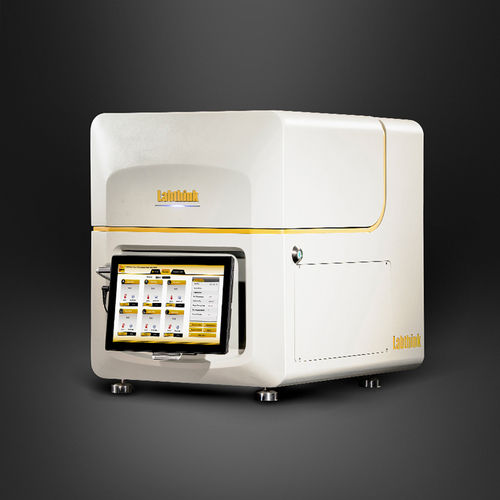

Intelligent

The instrument is equipped with the latest operating software, with user-friendly operating interface and intelligent data management functions. It also supports LystemTM Lab Data Sharing System, which ensures uniform management of test results and test reports.

- Based on the user-friendly Windows operating interface for easy operation

- Saves test data in different formats for convenient data transfer

- Intelligent historical data searching, comparing, analyzing and printing functions

- Supports LystemTM Lab Data Sharing System for uniform and systematic management of test results and test reports

Principle

Under a certain test temperature, a constant humidity difference is generated between two sides of the test specimen. The water vapor permeates through the specimen and into the dry side. By measuring the weight changes of the test dish in different time, water vapor transmission rate and other parameters can be obtained.

Standards

This test instrument conforms to the following standards:

ISO 2528, GB 1037, GB/T 16928, ASTM E96, ASTM D1653, TAPPI T464, DIN 53122-1, JIS Z0208, YBB 00092003

Applications

This instrument is applicable to the determination of water vapor transmission rate of:

| Basic Applications |

|---|

|

|

|

|

| Extended Applications |

|

|

|

|

|

|

|

Technical Specifications

| Specifications | Film Test |

|---|---|

| Test Range | 0.110,000 g/m224h (Water Method) 0.12,500 g/m224h (Desiccant Method) |

| Number of Specimens | 16 with independent test results |

| Accuracy | 0.01 g/m224h |

| Resolution | 0.001 g (Customization Available) |

| Temperature Range | 15C55C (standard) |

| Temperature Accuracy | 0.1C(standard) |

| Humidity Range | Water Method: 90%RH 70%RH Note1 |

| Desiccant Method: 10%RH98%RH Note2 | |

| Humidity Accuracy | 1%RH |

| Air Velocity | 0.52.5 m/s (customization available) |

| Specimen Thickness | 3 mm (customization is available for other thickness) |

| Test Area | 33 cm2 |

| Specimen Size | I74 mm |

| Test Chamber Size | 45 L |

| Gas Supply | Air |

| Gas Supply Pressure | 0.6 MPa |

| Port Size | I6 mm PU tubing |

| Instrument Dimension | 660 mm (L) x 580 mm (W) x 580 mm (H) |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Net Weight | 80 kg |

Note1: Herein the "Humidity means the humidity difference between the two sides of the film specimen. The humidity in the test chamber is 10%30%RH accordingly.

Note2: Herein the "Humidity means the humidity difference between the two sides of the film specimen. The humidity in the test chamber is 10%RH-98%RH when the temperature is 15 to 40 C, 10%RH-90%RH when the temperature is 45 C, 10%RH-80%RH when the temperature is 50 C, 10%RH-70%RH when the temperature is 55 C.

Configurations

- Standard Configurations

- Instrument, Professional Software, Test Dishes, Desiccant Tube, Humidity Generator, Calibration Weight, Communication Cable, Round Sample Cutter and Valve Set

- Optional Parts

- Satellite Base, Reference Film, Air compressor and Desiccant

- Note

- 1. The gas supply port of the instrument is I6 mm PU tubing;

2. Customers will need to prepare for gas supply and distilled water.

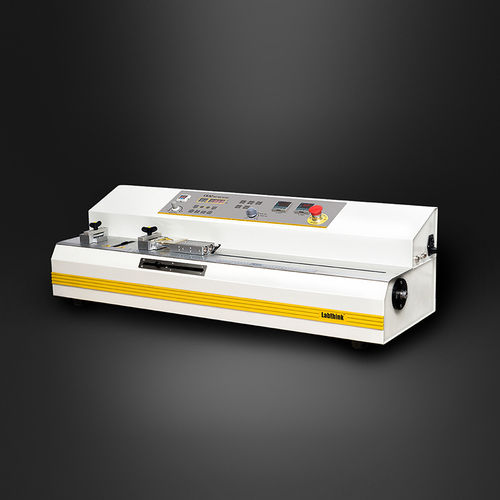

Accurate Multi-Method Testing

Featuring both gravimetric (cup method) and electrolytic sensor methods, this instrument enables comprehensive analysis of water vapor barrier properties across a broad spectrum of materials. Test parameters including humidity, temperature, and speed are programmable, ensuring customizable and repeatable results in accordance with international standards such as ASTM E96 and ISO 2528.

High-Efficiency, Automated Operation

With a fully automatic control system, digital LCD touch display, and memory capacity for up to 1000 results, this tester supports high-throughput workflows (up to 100 tests/day). Simultaneous testing of three specimens increases productivity, while built-in leak detection, real-time monitoring, and automatic calibration enhance data reliability.

Robust Design and Flexible Integration

Crafted from corrosion-resistant stainless steel, the instrument endures demanding laboratory environments. Its benchtop design, 6 mm quick connect gas ports, multiple interface types (RS232, USB), and compatibility with MODBUS and TCP/IP protocols ensure seamless integration into modern laboratory and manufacturing settings.

FAQ's of Water Vapor Barrier Testers for Barrier Materials:

Q: How does the Water Vapor Barrier Tester measure water vapor transmission rates?

A: The tester employs both gravimetric (cup method) and electrolytic sensor methods to measure water vapor transmission rates (WVTR). The gravimetric method tracks weight changes of a specimen sealed cup, while the electrolytic sensor detects moisture vapor passing through the test film. This dual approach ensures precise data across the full measuring range.Q: What materials and applications can be tested with this equipment?

A: The instrument is suitable for barrier materials such as films, packaging, and laminates. It is widely used in laboratory and quality control settings for industries involved in food packaging, pharmaceuticals, and flexible electronic manufacturing, testing the moisture barrier performance of materials.Q: When should I perform calibration on the tester?

A: Calibration is performed automatically using a certified reference film. The tester is designed to maintain high accuracy and repeatability, but users should follow any manufacturer-recommended intervals or recalibrate as needed for critical applications or after significant environmental changes.Q: Where can this Water Vapor Barrier Tester be installed and operated?

A: This benchtop tester is ideal for laboratory environments with ambient, non-condensing conditions between 5C and 35C. It is constructed from corrosion-resistant stainless steel to resist chemical exposure and is suitable for quality control laboratories, research institutions, and manufacturing sites.Q: What is the process for conducting a test using the instrument?

A: Users mount up to three specimens (115 mm diameter) onto the machine, set the desired test parameters (humidity, temperature, test speed, and width), and initiate the programmed test via the touchscreen control. The instrument automatically conducts the test, monitors real-time data, and stores results for review and analysis.Q: How can test results be exported and analyzed?

A: Test results are stored internally for up to 1000 completed tests. Data can be exported via RS232 or USB interfaces and is fully compatible with Windows-based software for further analysis. MODBUS and TCP/IP support also facilitates networked laboratory data management.Q: What are the key benefits of using this Water Vapor Barrier Tester?

A: The tester offers precise, automated, and customizable WVTR measurement, high throughput, and compliance with global testing standards. Safety features like overload protection and emergency stop provide operator security, while compatibility with modern laboratory systems streamlines operations and delivers reliable quality control insights.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese