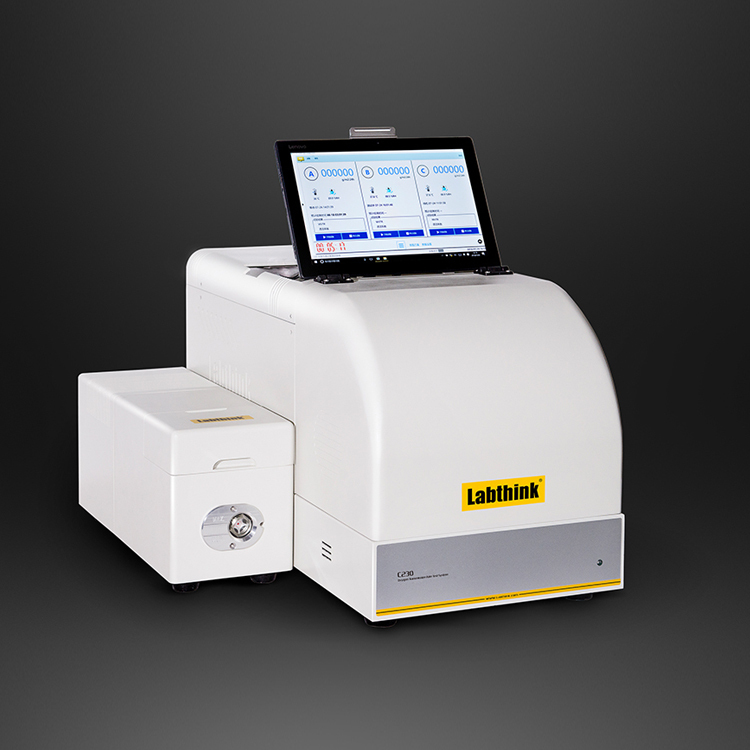

Breathability Tester for Gas Permeability Tests

Product Details:

- Specimen Size 110 mm diameter

- Features Automatic data logging, Calibration system

- Measuring Range 0.01 to 10000 g/m24h

- Max Height 450 mm

- Gas Pressure 0.1-1.0 MPa adjustable

- Operating Voltage AC220V

- Accuracy 0.5% of reading

- Click to View more

Breathability Tester for Gas Permeability Tests Price And Quantity

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

- 1 Set

Breathability Tester for Gas Permeability Tests Product Specifications

- Standard 12 mm diameter

- Tabletop

- 0.01 to 10000 g/m24h

- Automatic data logging, Calibration system

- 0.1-1.0 MPa adjustable

- AC220V

- 0.5% of reading

- 0.01 to 10000 g/m24h

- 450 mm

- Digital Control

- Variable 10-60mm/min

- 110 mm diameter

- Gas permeability and breathability testing

- AC 220V, 50/60Hz

- 50/60 Hz

- Up to 250 mm

- Breathability Tester for Gas Permeability Tests

- Single/Batch mode

- 5C to 50C

- <2 seconds

- Textile, Non-woven, Film, Medical, Packaging

- Semi-Automatic

- 0.01 g/m24h

- 38 kg

- 1 to 3

- Max 100 mm

- LCD Digital Display

- 20% - 95% RH

- RS232/USB

Product Description

Product FeaturesNote1

- Applicable to testing the permeability of various gases (exclude flammable, explosive and other hazardous gases)

- Support temperature control to satisfy tests under different conditions (optional)

- The processes of vacuumizing, pressure maintaining, start test and end test are automated.

- Automatic and manual test mode.

- Built-in high-quality stainless steel test cell with better sealing performance.

- Imported manual isolation valve is adopted for better sealing performance and lower failure rate

- Industrial computer appearance design, small size and fast cooling

- Reference film is provided for quick calibration

- The system adopts single-chip microcomputer control and can run independently

- The test report can be exported in common formats such as EXCEL and PDF

- Support micro printer, automatically print test data (optional)

- Equipped with RS232 data interface, which can be connected to computer software for curve analysis, data storage, report printing, etc. (optional)

Test Principle

The pre-conditioned specimen is mounted in the test cell as to form a sealed barrier between two chambers. The lower-pressure chamber (lower chamber) is firstly evacuated, followed by the evacuation of the entire cell. A flow of gas is thereafter introduced into the evacuated higher-pressure chamber (upper chamber) and a constant pressure (adjustable) difference is generated between the two chambers. The gas permeates through the specimen from higher pressure side into the lower pressure side. The gas permeability of the specimen can be obtained by analyzing the pressure changes in the lower chamber.

Standard

ISO 15105-1ISO 2556GB/T 1038-2000ASTM D1434JIS K7126-1YBB 00082003

Applications

| Applications |

|---|

|

|

Technical Specifications

Table 1: Test Parameters Note2

| Parameters/Model | C101B | |

|---|---|---|

| Testrange | cm3/m224h0.1MPa | 0.15,000 |

| Resolution | cm3/m224h0.1MPa | 0.01 |

| Test temperature | 1550Optional | |

| Temperature resolution | 0.1 | |

| Temperature fluctuation | 0.5 | |

| Vacuum Resolution | Pa | 1 |

| Vacuum Degree of Test Chamber | Pa | 20 |

| Pressure difference | kPa | 101 |

| Additional Functions | GMP Computer System requirement | Optional |

| TC03 Temperature control device | Optional | |

Table 2: Technical Specifications

| Test Cell | 1 Cell |

|---|---|

| Specimen Size | 3.8 x 3.89.7cm9.7cm |

| Specimen Thickness | 120 Mil3mm |

| Standard test area | 38.48cm2 |

| Test Gas | O2N2CO2 etc.Outside of supply scope |

| Gas Pressure | 72.5 PSI / 500 kPa |

| Port Size | 6 mm PU tubing |

| Instrument Dimension | 12.9 H x 16.9 W x 15.7 D (33cm 43cm 40cm) |

| Power Supply | 120VAC10% 60Hz / 220VAC10% 50Hzone of two |

| Net Weight | 50Lbs23kg |

Table 3: Product Configuration

| Standard Configuration | Instrument mainframe, vacuum pump (China), sampler, vacuum grease, 6 mm PU tubing |

|---|---|

| Optional Parts | Professional software, TC03 temperature control device, GMP Computer System requirement, Micro-printer |

Note 1: The described product functions are subject to the specification in "Technical Parameters" "Table 1: Test Parameters".

Note 2: The parameters in the table are measured in Labthink laboratory by professional operators according to the requirements and conditions stapulated in laboratory environmental standards.

Versatile Gas Permeability Assessment

Engineered to accommodate oxygen, nitrogen, carbon dioxide, and other custom gases, this breathability tester is adaptable for a diverse range of testing needs. It covers applications for the textile, film, medical, and packaging industries with variable test speeds and precise gas pressure controls. This flexibility ensures optimal testing conditions for different material requirements.

Advanced Automation and User-Friendly Operation

The testers semi-automatic functions include auto-calibration and digital controls that streamline setup and minimize operational errors. Its multilingual operation interface and LCD digital display enhance accessibility worldwide, making it ideal for global dealers, manufacturers, and suppliers. Remote control and in-depth analysis are enabled through bundled PC connectivity software.

Compliance, Safety, and Data Management

Certified to leading international standards such as ASTM D1434 and ISO 2556, the device assures test reliability and consistency. Integrated overpressure and overtime alarms guarantee safe operation. Test results can be exported in CSV or Excel formats, supporting efficient laboratory workflow and seamless integration into quality management systems.

FAQs of Breathability Tester for Gas Permeability Tests:

Q: How does the Breathability Tester ensure accurate gas permeability measurements?

A: The tester utilizes auto-calibration, precise digital controls, and high-resolution sensors to measure permeability across various gases. Accurate results are guaranteed by robust hardware conforming to ASTM D1434, ISO 2556, and other international standards, with a measurement accuracy of 0.5%.Q: What gases can be tested using this permeability tester?

A: You can test oxygen, nitrogen, carbon dioxide, and custom gases, making it suitable for various research and industrial applications in textiles, packaging, films, and medical materials.Q: When should I use the batch mode versus single-sample mode?

A: Batch mode is ideal for high-throughput labs requiring multiple sample analyses simultaneously (up to 3 specimens), while single-sample mode is suited for individualized, in-depth evaluations or when sample availability is limited.Q: Where can I export and analyze test data from this machine?

A: Test data can be automatically exported in CSV or Excel formats via the RS232 or USB interface. The included PC software enables remote control, data logging, and in-depth analysis conveniently on your computer.Q: What is the process for calibrating the Breathability Tester?

A: Calibration is fully automated through the built-in auto-calibration system, which the user initiates through the control interface. This ensures consistent accuracy and adherence to international test standards without manual intervention.Q: How do the alarm and safety features work on this instrument?

A: The device features real-time overpressure and overtime alarms to maintain safe operating conditions. These alarms immediately notify users and, if necessary, halt testing to prevent equipment or sample damage.Q: What are the key benefits of using this Breathability Tester for my laboratory or production line?

A: Key benefits include precise and reliable measurements, compliance with multiple standards, user-friendly digital operation, multilingual support, flexible test parameters, efficient data management, robust construction, and adaptable single or batch test capacitiesmaking it a leading solution for breathability testing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Gas Permeability Testers' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese