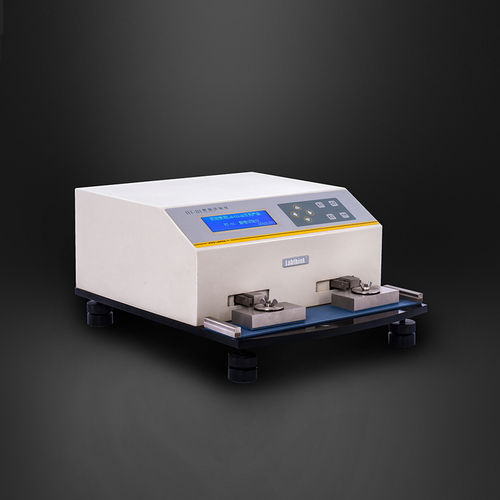

Ink Rub Tester used for printing of plastic bag with Sutherland rub test standard

50000 USD ($)/Set

Product Details:

- Equipment Type Ink Rub Tester

- Specimen Size 60 mm 110 mm

- Power Supply 220V AC, 50 Hz

- Accuracy 1 cycle

- Operating Voltage 220V AC 10%, 50/60 Hz

- Resolution 1 cycle

- Humidity 20% 90% RH

- Click to View more

X

Ink Rub Tester used for printing of plastic bag with Sutherland rub test standard Price And Quantity

- 50000 USD ($)/Set

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

Ink Rub Tester used for printing of plastic bag with Sutherland rub test standard Product Specifications

- 60 mm

- Instantaneous

- 50/60 Hz

- Digital touch screen control

- 09999 cycles

- Printing rub resistance test for plastic bags, paper, laminated films, and labels

- Standard: 2 lb and 4 lb weights

- Standard panel interface

- Digital LCD

- 2 (Upper and Lower)

- Semi-automatic

- Conforms to Sutherland rub test standard, adjustable speed and load, easy specimen mounting

- Approx. 30 kg

- 09999 cycles

- 15C 35C

- 21, 43, 85, and 106 cycles/min (selectable)

- Bench-top

- 20% 90% RH

- 1 cycle

- 60 mm

- Laboratory or production quality control

- 220V AC 10%, 50/60 Hz

- 1 cycle

- 220V AC, 50 Hz

- 60 mm 110 mm

- Ink Rub Tester

Product Description

Features of Ink Rub Tester

- 4 test modes of dry rub, wet rub, wet transfer, and wet smear and 4 different test speeds to meet different test requirements

- Dual stations with arc movement structure can test equivalent or distinct specimens simultaneously

- Intelligent design of power failure memory and buzzer reminding ensure the safety of test operation

- The instrument is controlled by micro-computer, with PVC operation panel, LCD and menu interface, which is convenient for users to operate or view the test data

Testing Standards

This test instrument conforms to the standard: ASTM D5264, TAPPI T830

Testing Applications

RT-01 Ink Rub Tester is applicable to the determination of abrasion resistance of:

| Basic Applications |

|---|

|

|

Technical Specifications

| Specifications | RT-01 Ink Rub Tester |

|---|---|

| Rub Pressure | 8.9 N(2lb); 17.8N(4lb) |

| Rub Speed | 21, 42, 85, 106 cpm |

| Rub Mode | Arc Reciprocating Movement |

| Rub Times | 0 999999 |

| Number of Specimens | 1 2 |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Instrument Dimension | 485 mm (L) x 390 mm (W) x 230 mm (H) |

| Net Weight | 40 kg |

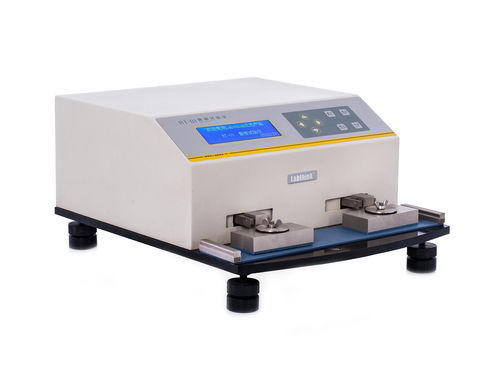

Configurations

- Standard Configurations

- Instrument, 8.9N (2lb) Test Block, 17.8N (4lb) Test Block and Rubber Cushion

- Optional Parts

- Customized Test Block

Efficient and Accurate Testing

This Ink Rub Tester is calibrated to deliver highly accurate results for rub resistance tests, with a measurement resolution of 1 cycle and an accuracy of 1 cycle. Its customizable specimen holder grips and instant digital LCD readouts make every test seamless. Robust construction and safety features like automatic stop and overload protection ensure operator security and consistency in testing routines.

Multi-Speed and Adjustable Loading

The tester provides selectable speeds of 21, 43, 85, and 106 cycles per minute and the option to switch between standard 2 lb and 4 lb weights, accommodating various material and testing requirements. Whether testing plastic bags, paper, or laminated labels, users can tailor the load and speed to suit specific quality control protocols.

User-Friendly Control and Versatile Application

Featuring a digital touch screen interface, the Ink Rub Tester streamlines setup and monitoring during operation. Designed for both laboratory and production environments, it can handle a wide humidity range (20%90% RH) and temperatures between 15C and 35C, making it adaptable for different facility conditions and test specimen types.

FAQs of Ink Rub Tester used for printing of plastic bag with Sutherland rub test standard:

Q: How does the Ink Rub Tester conform to the Sutherland rub test standard?

A: The Ink Rub Tester adheres to the Sutherland rub test standard by allowing adjustable speed and load settings, precise cycle measurement, and reliable test conditions. Its automatic calibration and certification further ensure compliance with internationally recognized procedures for rub resistance testing.Q: What materials and products can be evaluated using the Ink Rub Tester?

A: This equipment is suitable for testing the rub resistance of inks on plastic bags, paper, laminated films, and labels, commonly used in packaging and printing industries.Q: When should a user choose between manual or automatic load selection for testing?

A: Manual or automatic load selection enables the operator to apply either 2 lbs or 4 lbs based on material toughness or specific industry standards. Automatic selection is recommended for repetitive quality checks, while manual mode provides flexibility during customized or research-focused tests.Q: Where is the Ink Rub Tester best employed?

A: The tester is ideal for laboratory and production quality control settings, such as packaging converters, printing facilities, and material suppliers. It is designed for bench-top mounting, fitting well in workflow stations and QC labs.Q: What is the process for mounting and testing a specimen?

A: Specimens are mounted using the customizable grips on the sample holders (for sizes 60 mm x 110 mm). The user selects the required test parameters using the digital touch screen interface and initiates the test, which automatically stops at the end of the selected cycle or in case of overload for added safety.Q: How does the Ink Rub Tester benefit quality assurance in printing applications?

A: It ensures the durability of printing by accurately measuring rub resistance, helping manufacturers minimize print wear and improve product performance. Reliable, repeatable tests enhance confidence in packaging quality and reduce material wastage by identifying potential issues early.Q: What accessories are included with the Ink Rub Tester and how do they support operation?

A: Accessories such as standard weights, an instruction manual, and a calibration certificate are provided to facilitate accurate testing, compliance verification, and user guidance throughout operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Ink Rub Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese