Permeability Testing Critical Considerations for Ensuring High Barrier Package Integrity

Product Details:

- Operating Voltage 220 V

- Application High barrier package integrity testing

- Port Size Standard 1/8 inch NPT

- Humidity 30% 90% RH

- Specimen Size Up to 150 150 mm

- Features High sensitivity sensors, automatic calibration

- Test Range 0.005 500 cc/m/day

- Click to View more

Permeability Testing Critical Considerations for Ensuring High Barrier Package Integrity Price And Quantity

- 50000 USD ($)/Set

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

Permeability Testing Critical Considerations for Ensuring High Barrier Package Integrity Product Specifications

- 220 V

- Approx. 48 kg

- High barrier package integrity testing

- Multiple test modes supported

- 1 - 10 mm/min adjustable

- Standard 1/8 inch NPT

- 150 mm

- 0.005 500 cc/m/day

- Digital LCD

- 30% 90% RH

- Up to 150 150 mm

- High sensitivity sensors, automatic calibration

- 0.001 cc/m/day

- Full automatic

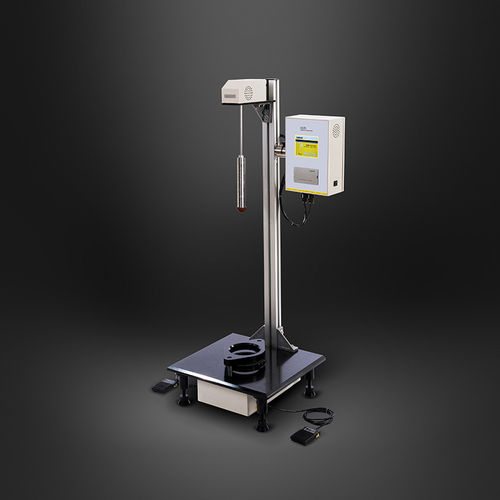

- Bench-top

- Single or multi-station (up to 3)

- Applicable for flexible and rigid materials

- 500 mm

- Up to 200 mm

- USB, RS232

- 0.01 500 cc/m/day

- < 5 sec

- 50 Hz

- Ambient to 60C

- 220 V AC, 50 Hz

- Industrial laboratory testing

- 1% of reading

- Microprocessor-based automatic

- 0.1 1 MPa

Product Description

Product FeaturesNote1

Innovative structure design & upgraded automatic operation

- Test cells with brand new pop-up drawer type design

- Automatic specimen clamping with uniform force

- Components are supplied by global well-known manufacturers, which are reliable and stable in performance

- Intelligent test mode, one-button test operation (test temperature should be set in advance) and automatic stop

- Scientific research mode provides more flexible parameter and function settings for analysis of gas transmission rate, solubility coefficient, diffusion coefficient and permeability coefficient

Upgraded testing accuracy and efficiency

- Imported high precision vacuum sensor for tests of ultra-high barrier property (0.01 0.09 cm3/ m224h0.1MPa) materials with high accuracy and repeatability

- Imported pneumatic control system with ultra-low failure rate and extremely long service life, which guarantees the seal performance of the whole system

- Imported high precision vacuum pump improves the evacuation efficiency and generates vacuum up to 0.2Pa

- The vacuum pump is turned on/off automatically

- For low and medium barrier property materials, test time is less than 4 hours (including evacuation time)

- For high barrier property materials, test time is less than 8 hours (including evacuation time)

- Three independent test cells provide individual test results, specimens can be replaced as desired

Excellent temperature and pressure control technique

- 360circulation constant temperature technology is applied in the instrument to remain the test temperature fluctuation below 0.05C

- Labthinks unique pressure compensation technique is used to maintain the stable differential pressure (pressure change is less than 0.2KPa)

- The pressure of high pressure chamber can be adjusted from 10KPa to 210KPa and maintained precisely

Versatile functions based on standards, customization available

- Various types of gases are testable: sole gas, mixed gases, poisonous gases, explosive gases and other dangerous gases (customization is required)

- The humidity of test gas can be adjusted and controlled automatically by the system, without requiring human intervention (customization is required for humidifying device)

- Labthinks unique data fitting function can provide the test results of gas transmission rate, permeability coefficient, solubility coefficient and diffusion coefficient at extreme temperatures

- Reference film for fast calibration ensures accurate and universal test data

- Calibration port for verifying test temperature and pressure

- Conform to the test standards of differential pressure method

High end, secure and easy-to-use embedded computer controlled system

- Integrated design of instrument and software minimizes the malfunctions caused by computer virus or faulty operations and ensures the performance of the instrument and data security

- The instrument can be easily operated with a mouse, a keyboard and a monitor. Windows operation interface for testing operations and displaying data

- The system is equipped with four USB ports and dual Internet ports for convenient data transmission

- The instrument meets the requirements of China GMP of pharmaceutical industry (optional)

- Labthinks unique DataShieldTM system for data management and connecting information management system (optional)

Test Principle

C130H is designed in accordance with differential pressure method. The pre-conditioned specimen is mounted in the gas diffusion cell as to form a sealed barrier between two chambers. The lower-pressure chamber is firstly evacuated, followed by the evacuation of the entire cell. A flow of gas is thereafter introduced into the evacuated higher-pressure chamber and a constant pressure difference is generated between the two chambers. The gas permeates through the specimen from higher pressure side into the lower pressure side. The gas permeability and other barrier properties of the specimen can be obtained by monitoring the pressure changes in the lower chamber.

Test StandardNote1

ISO 2556, ISO 15105-1, GB/T 1038-2000, ASTM D1434, JIS K7126-1, YBB 00082003

ApplicationsNote1

This instrument is applicable to the determination of gas permeability of:

| Basic Applications |

|---|

|

|

| Extended Applications |

|

|

|

|

|

|

|

|

|

Technical SpecificationsNote2

| Specifications | Film Test |

|---|---|

| Test Range | 0.01 50,000 cm3/m224h0.1MPa |

| Resolution | 0.001 cm3/ m224h0.1MPa |

| Temperature Range | 10C 50C (room temperature 23C) |

| Resolution | 0.01C |

| Temperature Fluctuation | 0.05C |

| Temperature Accuracy | 0.3C (calibration port) |

| Vacuum Resolution | 0.01Pa |

| Vacuum Accuracy | Displayed Value 0.2% (1%100% of sensor range) |

| Vacuum Degree of Test Chamber | < 10 Pa |

| Number of Specimens | 3 with independent test results Customization available for other number of specimens |

| Specimen Size | I97 mm |

| Test Area | 38.48 cm2 |

| Test Gas | O2, N2, and CO2 (outside of supply scope) Humidifying of Test Gas (customization available) |

| Test Pressure | 10KPa 210KPa |

| Gas Supply Pressure | 0.5 Mpa 0.6 Mpa (73psi 87psi ) |

| Port Size | I6 mm PU Tubing |

| Instrument Dimension | 710 mm (L) 350 mm (W) 630 mm (H) |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Net Weight | 100 kg |

Configurations

- Standard Configurations

- Instrument, Monitor, Keyboard, Mouse, Round Sample Cutter, Vacuum Grease, Fast Quantitative Filter Paper and Vacuum Pump, I6 mm PU tubing (3m)

- Optional Parts

- GMP Computer System, DataShieldTM Note3, Air Compressor

- Note

- 1. The gas supply port of the instrument is I6 mm PU tubing;

2. Customers need to prepare gas supply.

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

Advanced Analytical Precision for Barrier Materials

Utilizing the differential pressure method and cutting-edge sensors, this Permeability Tester delivers accurate measurement of gas transmission rates in high barrier packaging. It supports a wide measuring range to meet the diverse needs of modern packaging research and quality control labs. The fully automatic control system ensures repeatable and reliable test outcomes for both flexible and rigid samples.

User-Friendly Interface and Data Management

A digital LCD display and intuitive graphical analysis software simplify operation, while internal memory enables robust data storage and export to Excel or LIMS. Calibration is automatic and traceable, reducing manual interventions and enhancing consistency. The system includes multiple test modes and adjustable parameters to customize testing protocols quickly.

Robust Safety and Support Features

Engineered for industrial reliability, the tester integrates overpressure protection, a sealed test chamber, and shock-proof packaging. With onsite installation and annual calibration services available, users benefit from high uptime and compliant results. The instrument's construction is suited for controlled lab conditions, ensuring operational safety and data integrity.

FAQ's of Permeability Testing Critical Considerations for Ensuring High Barrier Package Integrity:

Q: How does the differential pressure method work in this Permeability Tester?

A: The tester applies the differential pressure method, where a controlled pressure difference is established across a test specimen using gases like oxygen, water vapor, or CO2. Highly sensitive sensors detect gas flow through the sample, allowing for precise calculation of permeability rates according to ASTM F1249 and ISO 15106 standards.Q: What are the key benefits of using this Permeability Tester for high barrier packaging integrity?

A: This tester ensures high accuracy (1% of reading) and rapid response (<5 seconds) in measuring gas transmission, safeguarding barrier properties of packaging. Fully automated calibration ensures consistent results, while compliance with CE and RoHS standards supports regulatory adherence. Packed with automatic safety and support features, it reduces risk and maximizes efficiency.Q: When and how often should the equipment be calibrated or maintained?

A: Annual calibration is recommended to sustain measurement accuracy, with automated calibration routines traceable to international standards included. Users can also schedule onsite service and training during installation to maintain performance and ensure compliance with quality systems.Q: What gases and test conditions are supported by the instrument?

A: The tester accommodates oxygen, water vapor, and CO2 under controlled conditions. It operates within 0.1 - 1 MPa gas pressure, 30%-90% RH humidity, and ambient to 60C temperature, enabling flexible testing of various packaging formats and barrier levels.Q: How can results be stored and exported for analysis?

A: Test data are saved in the internal memory of the instrument and can be easily exported to Excel or Laboratory Information Management Systems (LIMS) via USB or RS232 interfaces. Advanced graphical software provides real-time analysis and visual representation for efficient result interpretation.Q: Where should the Permeability Tester be used for optimal performance?

A: The instrument is best operated in a temperature-controlled, low vibration laboratory setting-factors critical for ensuring data precision. Its bench-top design accommodates most industrial and research laboratory environments, and the shock-proof packaging streamlines its transport and installation.Q: What types and sizes of specimens can be tested, and how many samples can be managed at once?

A: This tester accommodates flexible and rigid samples up to 150 150 mm in size. It supports both single and multi-station configurations, allowing simultaneous testing of up to three specimens for increased throughput.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |