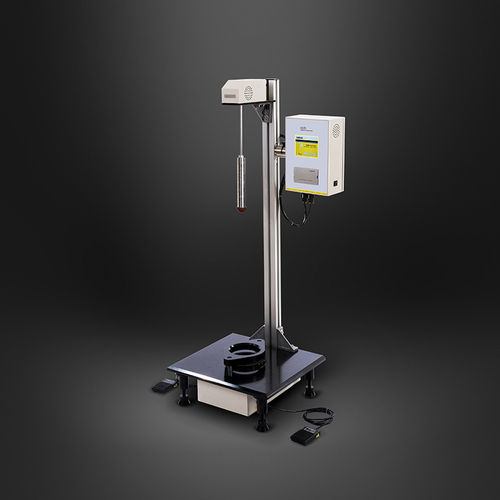

Tag Adhesive Tester to Guarantee High-Quality Cosmetic Packaging

Product Details:

- Max Height 350 mm

- Operating Voltage 220V

- Accuracy 1% of reading

- Resolution 0.01 N

- Gas Pressure 0.6 MPa

- Application Cosmetic packaging adhesive strength testing

- Hardness Test Fixture Hard anodized

- Click to View more

Tag Adhesive Tester to Guarantee High-Quality Cosmetic Packaging Price And Quantity

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

Tag Adhesive Tester to Guarantee High-Quality Cosmetic Packaging Product Specifications

- 220V AC 50 Hz

- Tag Adhesive Tester

- 50-500 mm/min adjustable

- Tabletop

- 50 Hz

- Test Fixture Hard anodized

- Cosmetic packaging adhesive strength testing

- 0.6 MPa

- 1% of reading

- 0.01 N

- 220V

- 350 mm

- 50 mm

- 0.01-30 N

- 50 x 150 mm

- 1

- 45 Kg

- 1/4 inch

- <0.8 sec

- 15-35C

- RS232

- Digital LCD

- 300 mm

- 30 N

- Automatic

- Microporcessor based control

- 40-85% RH

- Adhesive strength and peel test measurement

- 0-30 N

- Auto calibration, Overload protection, Removable specimen holder

Product Description

Product FeaturesNote1

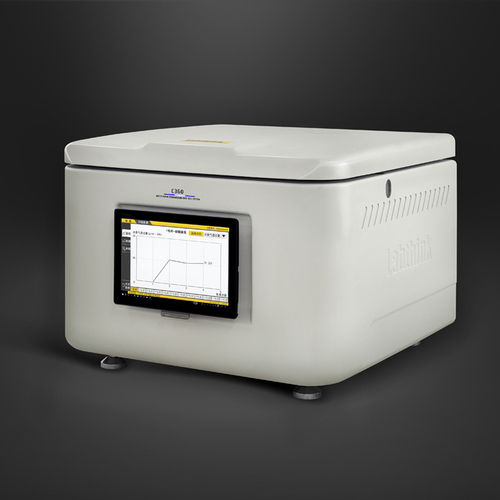

Professional Test Modes to Meet Various Testing Demands

- Multiple independent test modes including tensile test, peel test, tearing test, heat seal test, tensile test at fixed elongation, and compression test, etc. at users choice

- The instrument supports bidirectional testing modes and test speed can be adjusted freely

- Intelligent designs of over-travel protection, overload protect and automatic position reset guarantee safe test operation of the users

Excellent Testing Mechanism & Improved Test Accuracy

- Force measuring system is supplied by top global supplier, which ensures the testing accuracy of better than 0.5% of full scale and guarantees accurate test results and good repeatability. Multiple test ranges can be selected freely.

- Servo control system powered by top global supplier and the patented high-precision ball screw multi-point positioning technology provide displacement accuracy of better than 0.5% of full scale and infinitely variable speed, facilitate the instrument with simplified and stable operation.

- Global renowned brand pneumatic control system supports pneumatic specimen clamping, which avoids the specimen slipping and guarantees the accuracy of test data

High-end, Secure and Easy-to-Use Embedded Computer-controlled System

- Large size touch screen tablet for better viewing and easy operation

- Brand new software and system provide smooth and simplified operating experience

- The system supports displaying and comparison analysis of group of test data as well as unit conversions of test results.

- Labthinks unique data security design by separating the test data from the computer, totally avoids the system software malfunctions caused by computer virus or faulty operations, conforms to the requirements for data traceability of China GMP (optional).

- The instrument is equipped with USB ports and Internet ports for convenient data transmission.

- Unique DataShieldTM system supports centralized management of test data and can be connected to other information management system.

Test StandardNote1

ISO 37, ASTM E4, ASTM D882, ASTM D1938, ASTM D3330, ASTM F88, ASTM F904, JIS P8113, GB 8808, GB/T 1040.1-2006, GB/T 1040.2-2006, GB/T 1040.3-2006, GB/T 1040.4-2006, GB/T 1040.5-2008, GB/T 4850-2002, GB/T 12914-2008, GB/T 17200, GB/T 16578.1-2008, GB/T 7122, GB/T 2790, GB/T 2791, GB/T 2792, GB/T 17590, QB/T 2358, QB/T 1130

Applications

C610H is equipped with more than 100 grips for tests of more than 1000 materials. Customization is available for special material tests. Examples of instrument applications:

| Basic Applications | |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Extended Applications (Additional Accessories Required) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Technical SpecificationsNote2

| Specifications | C610H Auto Tensile Tester |

|---|---|

| Load Cell Capacity | 500 N (standard) 50 N, 100 N, 250 N, 1000 N (optional) |

| Accuracy | 0.5% of indicated value (2%FS100%FS) 0.01%FS (0% 2%FS) |

| Resolution | 0.001 N |

| Test Speed | 0.05 500 mm/min |

| Speed Accuracy | 0.5% of indicated value (1%100% of maximum speed) |

| Number of Specimens | 1 |

| Specimen Width | 30 mm (Standard Grip) |

| 50 mm (Optional Grip) | |

| Clamping Way | Pneumatic Specimen Clamp |

| Gas Supply | Air (outside of supply scope) |

| Gas Supply Pressure | 0.5 MPa 0.7 Mpa (72.5psii101.5psi) |

| Stroke | 1000 mm |

| Instrument Dimension | 500 mm (L) 520 mm (W) 1900 mm (H) |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Net Weight | 110 kg |

Configurations

- Standard Configurations

- Instrument, Professional Software, Tablet, Pneumatic Sample Grips

- Optional Parts

- Standard Pressure Roller, Test Plate, Sample Cutter, Customized Grips, Laser Printer, Air Compressor, Computer System required by GMP, DataShieldTM Note3

- Note

- 1. The gas supply port of this instrument is I4mm PU Tubing;

2. Customers need to prepare gas supply.

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

Versatile and Accurate Testing Solution

Designed for cosmetic packaging, the Tag Adhesive Tester covers a measuring range from 0.01 to 30 N with 1% accuracy and a 0.01 N resolution. Its quick-release clamp with anti-slip pads and robust build allows efficient, precise peel and adhesive strength measurement. Automatic calibration and overload protection further enhance its operational reliability during testing cycles.

User-Friendly Features and Controls

This adhesive tester incorporates a digital LCD display for easy readings, memory for up to 100 measurements, and a microprocessor-based control system. Its automation, emergency stop button, and adjustable test speeds ensure testing processes are both safe and customizable for a variety of adhesive applications.

Built for Safety and Durability

Outfitted with a powder-coated industrial ABS exterior, export-quality foam-padded packaging, and hard-anodized test fixtures, the tester handles rigorous lab use and shipping. Safety features such as emergency stop and overload protection provide reliable operation and longevity, meeting the demands of busy manufacturing and QA environments.

FAQ's of Tag Adhesive Tester to Guarantee High-Quality Cosmetic Packaging:

Q: How does the Tag Adhesive Tester ensure accurate and consistent peel strength measurements?

A: The tester features digital automatic calibration and a microprocessor-based control system, allowing for rapid, precise test cycles. Its LCD display, high-resolution readings (0.01 N), and compliance with ASTM D3330/D1000 guarantee that the measurements are consistently accurate and reliable.Q: What is the process for conducting a peel test using this equipment?

A: First, set the desired test speed (between 50 and 500 mm/min). Secure the specimen (50 x 150 mm) in the quick-release clamp with anti-slip pads. Initiate the automatic test via the control panel, and results are displayed digitally. Up to 100 measurements can be stored for later review or export via the RS232 interface.Q: When should automatic digital calibration be performed on the tester?

A: The instrument features automatic digital calibration, typically initiated during power-on or as needed. Regular calibration ensures that the readings remain within the 1% accuracy range, maintaining consistent performance across multiple tests.Q: Where can this tester be installed and used most effectively?

A: Designed for tabletop mounting, the Tag Adhesive Tester is ideal for laboratory, quality control, and production areas within manufacturing or R&D facilities. Its compact, durable construction ensures stable operation wherever high-precision cosmetic packaging testing is needed.Q: What safety mechanisms are included in the Tag Adhesive Tester?

A: To protect users and equipment, the tester is equipped with an emergency stop button and overload protection. Its industrial ABS casing with powder coating and robust specimen holder further contribute to user safety and overall machine durability.Q: How does using the Tag Adhesive Tester benefit manufacturers and exporters of cosmetic packaging?

A: Manufacturers can guarantee product quality by ensuring adhesive seals meet required standards, reducing the risk of packaging failures. Exporters benefit from compliance with international test standards, enabling smoother market entry and reduced returns or complaints.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese