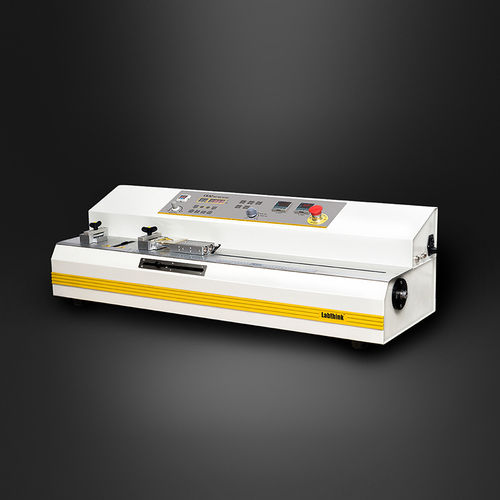

Heat Seal & Hot Tack Testers

50000 USD ($)/Set

Product Details:

- Response Time <150 ms

- Mounting Type Benchtop

- Power Supply AC 220V, 50Hz

- Accuracy 1% of full scale

- Measuring Range 1~50 N

- Test Range 1~50 N

- Application Testing sealing strength and hot tack strength of flexible plastic/film packaging materials

- Click to View more

X

Heat Seal & Hot Tack Testers Price And Quantity

- 50000 USD ($)/Set

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

Heat Seal & Hot Tack Testers Product Specifications

- Microprocessor Controlled

- Material laboratory analysis

- AC 220V, 50Hz

- <150 ms

- Benchtop

- Testing sealing strength and hot tack strength of flexible plastic/film packaging materials

- 1~50 N

- 1~50 N

- 1% of full scale

- Seal Jaw Hardness >60 HRC

- Approximately 36 kg

- 10 mm/sec to 500 mm/sec (adjustable)

- 380 mm

- Digital LCD Display

- RS232/USB

- Up to 15 mm

- Room temperature to 250C

- 0.01 N

- Fully Automatic

- Precision Laboratory Heat Seal & Hot Tack Tester

- Length 100 mm x Width 15 mm

- 0.4-0.7 MPa

- 20~90% RH

- 1~3 simultaneous tests

- 50 Hz

- Programmable temperature, time and pressure, data storage, print function

- 50 N (standard) / Customizable

- 6 mm pneumatic connector

- 220 VAC

- 0~100 mm (configurable)

Product Description

Product FeaturesNote1

Multiple Test Modes in One Instrument

- Four test modes including hot tack, heat seal, peel and tensile test.

- With Digital P.I.D. temperature control system, the preset temperature can be reached in a short time without fluctuations.

- Four force test ranges and 6 testing speeds are available to meet various testing requirements

- The instrument meets the requirement for testing speed specified in standard GB/T 34445-2017

Excellent Designs & Auto Sampling

- Auto sampling for hot tack test, simplifies the testing operation and minimizes errors, ensures the uniformity of test data

- Pneumatic sample clamping system (optional)

- Automatic zeroing, error alert, overload protection and stroke protection guarantee safe operations

- Instrument can be started manually or by pedal switch. it is convenient for the operator and the anti-scald design ensures safe operations

- Components and parts of the instrument are supplied by world renowned manufacturers and have reliable performance

Computer & Instrument Controlled Operations

- Test operations can be performed on the instrument or by the software

- The instrument can be operated without a computer, easy to operate and view test data

- Data I/O ports for data export

Test StandardNote1

GB/T 34445, ASTM F1921, ASTM F2029, QB/T 2358, YBB 00122003

Applications

| Basic Applications |

|---|

|

|

|

|

| Extended Applications |

|

|

|

|

|

|

Technical SpecificationsNote2

| Specification | C632B Hot Tack Tester |

|---|---|

| Load Cell Capacity | 30 N (Standard) 50 N 100 N 200 N (Optional) |

| Force Accuracy | Indicated Value 1% (10%-100% of load cell capacity) 0.1%FS (0%-10% of load cell capacity) |

| Force Resolution | 0.01 N |

| Test Speed | 150 200 300 500 hot tack 1500mm/min, 2000mm/min |

| Specimen Width | 15 mm, 25 mm or 25.4 mm |

| Stroke | 500 mm |

| Heat Seal Temperature | Room Temperature 250C |

| Temperature Variation | 0.2C |

| Temperature Accuracy | 0.5C (Single Point Calibration) |

| Dwell Time (Heat Seal Test) | 0.1 999.9 s |

| Dwell Time (Hot Tack Test) | 0.1 999.9 s |

| Sealing Pressure | 0.05 Mpa 0.7 MPa |

| Sealing Area | 100 mm x 5 mm |

| Sealing Jaws | Double (one is silicon rubber) |

| Gas Supply | Air (Not in supply scope) |

| Gas Supply Pressure | 0.7 Mpa (101.5psi) |

| Port Size | I4 mm PU Tubing |

| Instrument Dimension | 1120 mm (L) 380 mm (W) 330 mm (H) |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Net Weight | 45 kg |

Configurations

- Standard Configurations

- Instrument, Manual Clamp, Pedal Switch, Sampling Plate, Calibration Support, I4 mm PU Tubing (2m)

- Optional Parts

- Computer, Professional Software, Pneumatic Sample Grips, Air Compressor

- Note

- 1.The gas supply port of this instrument is I4 mm PU Tubing;

2.Customers need to prepare gas supply.

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

High-Precision Material Testing

Designed for reliable analysis of packaging materials, this heat seal & hot tack tester offers programmable parameters for temperature, pressure, and time. Its digital LCD display and fast response ensure accurate monitoring, making it a vital tool for researchers and manufacturers seeking consistent quality control.

Customizable Sealing Solutions

With options for flat and custom seal jaw shapes, configurable stroke length, and specimen capacity for simultaneous testing, laboratories benefit from versatile functionality. The equipment supports various test modes to accommodate a range of sample sizes and testing requirements.

Enhanced Data Handling and Safety

Real-time printing and data storage simplify record-keeping, while advanced protection features guard against overheat and overpressure incidents. The tester operates effectively in diverse environments with wide temperature and humidity tolerances, ensuring safety and reliability during extended use.

FAQ's of Heat Seal & Hot Tack Testers:

Q: How do I set up and calibrate the Heat Seal & Hot Tack Tester for accurate results?

A: You can calibrate the tester automatically through its built-in calibration function, or manually depending on laboratory requirements. Follow the on-screen digital LCD instructions to set jaw pressure, seal time, and temperature before running test cycles. Calibration options ensure consistent precision for each new batch of specimens.Q: What materials and packaging types can be analyzed using this equipment?

A: This tester is designed for flexible plastics and film packaging materials. It accommodates specimens up to 100 mm in length and 15 mm in width, enabling evaluation of sealing strength and hot tack properties essential to various packaging formats used across food, pharmaceuticals, and industrial goods.Q: When should I use programmable parameters such as time, pressure, and temperature in testing?

A: Programmable parameters are crucial for simulating real-world packaging conditions and meeting specific test standards. Adjust seal time, jaw pressure (0.1-1.0 MPa), and temperature (room temperature to 250C) to replicate production-level environments or comply with regulatory norms for material performance evaluation.Q: Where does the data from the tests get stored and how can it be accessed?

A: Test data are stored internally with a capacity for 500 records, accessible via the digital interface or output through RS232/USB for direct connection to a computer or printer. This enables efficient archiving, analysis, and compliance reporting as needed by laboratory protocols.Q: What is the typical process for running simultaneous specimen tests?

A: Load one to three specimens (each up to 100 mm x 15 mm) onto the seal jaws, program the desired test settings, and start the run via the microprocessor controls. The system will automatically process each specimen, record data in real time, and perform printing and storage of test results.Q: How does automatic safety protection benefit users during operation?

A: Overheat and overpressure protection mechanisms continuously monitor system status, automatically intervening if set limits are exceeded. This protects both operator and samples from accidental damage, ensuring reliable operation and extending equipment lifespan.Q: What are the advantages of using benchtop, fully automatic testers in laboratory analysis?

A: Benchtop, fully automatic testers streamline workflows by automating repetitive test routines, reducing manual errors, and providing high-speed data acquisition. They enhance productivity, accuracy, and traceability, ultimately improving the reliability of material testing and quality assurance processes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'OTR/WVTR Test System' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese