Accurate Oxygen Measurement for Optimal Drug Safety

Product Details:

- Application Drug packaging oxygen measurement

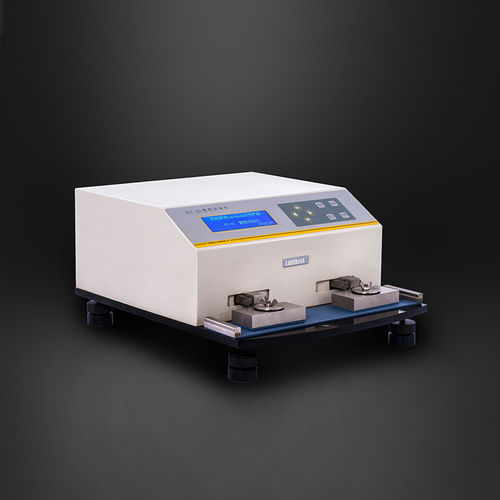

- Mounting Type Bench-top

- Test Range 0.01-1000 cc/m2/day

- Equipment Type Oxygen Transmission Rate Tester

- Interface Type RS232 / USB

- Power Supply AC 220V 10%, 50Hz

- Gas Pressure 0.1-0.8 MPa

- Click to View more

Accurate Oxygen Measurement for Optimal Drug Safety Price And Quantity

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

- 1 Set

Accurate Oxygen Measurement for Optimal Drug Safety Product Specifications

- AC 220V 10%, 50Hz

- 0.1-0.8 MPa

- 0.01 ~ 1000 cc/m2/day

- Pharmaceutical drug safety testing

- LCD digital display

- 1-99 mm/min adjustable

- Automatic

- 0.01 cc/m2/day

- Drug packaging oxygen measurement

- Bench-top

- 0.01-1000 cc/m2/day

- Oxygen Transmission Rate Tester

- RS232 / USB

- Max 100 mm

- Up to 120 mm

- 1% of reading

- 5C - 45C operating range

- Standard 8 mm

- 220 V

- Microprocessor based automatic control

- 3

- 100 mm100 mm

- Approximately 15 kg

- 100 tests/day

- 0-90% RH

- <5 sec

- 50 Hz

- 350 mm

- Automated, Data Logging, High Sensitivity

Product Description

Product FeaturesNote1

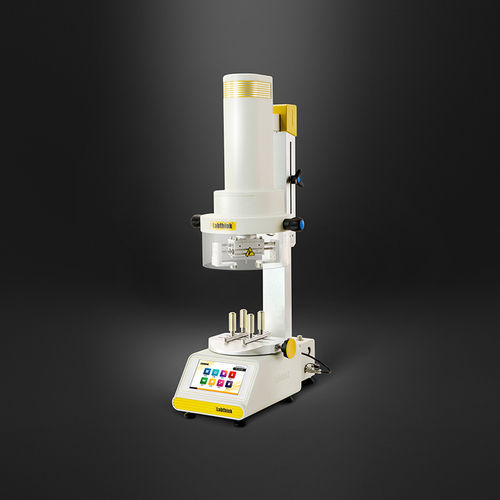

- Handheld and portable design, easy-to-operate with one hand, suitable for tests on production line

- Auto shutdown for energy saving

- One-button calibration, simple and efficient

- Components and parts are supplied by global well-known manufacturers, which guarantee stable performance of the instrument

- Protective cover for sampling probe to ensure the safety of the operator

- Embedded gas sensors for accurate analysis of the gas contents inside flexible or rigid packages

- Embedded pressure sensor for accurate determination of the vacuum degree inside the package

- CO2 sensor uses NDIR technology, patented solid state LED, detector and gold-plated optic components

- The sensors are supplied by globally well-known manufacturers, which have ultra-high precision, low fault rate and long service life

- Industrial grade touch screen, one button operation, intuitive operating interface, remote upgrade & maintenance

- Chinese and English language operating system can meet different requirements of the users

- Automatic data storage, power failure memory to prevent data loss

- Up to 1200 test results can be stored

- Equipped with wireless micro-printer for convenient data printing (optional)

- Equipped with standard USB ports and professional software for convenient PC connection and data transfer (optional)

Test Principle

The gas inside the test package is brought to the gas sensor by the air pump. The instrument analyzes the volume of oxygen and carbon dioxide (optional) contained in the sample gas by calculating the electrical signals generated by the gas sensor. When the preset condition is met, the test is completed and the system records the oxygen and carbon dioxide (optional) concentration.

Applications

| Basic Applications |

|---|

|

|

| Extended Applications |

|

Technical SpecificationsNote2

| Specifications | C650M | |

|---|---|---|

| Testable Gases | O2 (Standard) | CO2 (optional) |

| Test Principle | Electrochemistry | Infrared Absorption |

| Sensor Service Life | 2 Years (in air) | >15 Years |

| Test Range | 0 100% | 0 100% |

| Resolution | 0.01% | 0.01% |

| Test Accuracy | 0.2% | (0.03% + displayed value * 5%) |

| Sampling Volume | <2 mL (Standard Mode) | 15 mL (Standard Mode) |

| Instrument Dimension | 220mm (L) 110mm(W) 70mm(H) | |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz | |

| Net Weight | 0.6 kg | |

Configurations

- Standard Configurations

- Instrument, Sampling Probe, Filter, Seal Gasket

- Optional Parts

- Professional Software, Micro Printer, B2227 Test Frame for Headspace Gas Analyzer, B2226 Underwater Sampling Set, CO2 Sensor, Pressure Sensor

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: The picture in this brochure has included B2227 Test Frame for Headspace Gas Analyzer.

Precision Measurement for Drug Safety

Ensure exact oxygen permeability assessment in pharmaceutical packaging with our electrochemical oxygen sensor. Its high accuracy (1% of reading) and rapid response time (<5 seconds) help maintain optimal drug efficacy by detecting even minor changes in oxygen levels.

Advanced Automation and User-friendly Controls

Utilizing microprocessor-based automatic control, this tester streamlines the testing process. The LCD digital display, programmable parameters, and Windows-compatible software offer simple operation, while automated data logging maximizes traceability and compliance.

Robust Build and Safety Compliance

Built with durable stainless steel 304 and conforming to EN 61010-1 safety standards, this bench-top instrument is suitable for intensive, reliable use in manufacturing and laboratory environments. Comprehensive audible and visual alarms further safeguard operations.

FAQ's of Accurate Oxygen Measurement for Optimal Drug Safety:

Q: How does the electrochemical oxygen sensor contribute to accurate measurements in drug packaging?

A: The electrochemical oxygen sensor is highly sensitive, providing accurate readings within 1% of the actual value. This level of precision is crucial for detecting trace oxygen levels in pharmaceutical packaging, ensuring the safety and stability of drugs.Q: What is the process for calibrating the Oxygen Transmission Rate Tester?

A: Calibration is performed using a single-point method, ensuring quick and straightforward setup while maintaining measurement accuracy. Regular calibration ensures consistent, reliable performance for all your drug safety tests.Q: When should this tester be used during pharmaceutical quality control?

A: Employ the tester during or after drug packaging to assess oxygen permeability and confirm the packaging's integrity. Frequent use is recommended when verifying new packaging materials or batches for optimum drug protection.Q: Where can the Oxygen Transmission Rate Tester be installed?

A: This compact, bench-top device is suitable for laboratory and manufacturing settings in pharmaceutical facilities. Its robust stainless steel build and low noise output (<50 dB) make it a practical addition to quality control environments.Q: How does automatic data logging benefit pharmaceutical quality assurance?

A: Automated data logging stores up to 10,000 test records, eliminating manual entry errors and providing a comprehensive, traceable test history. This enhances compliance with regulatory standards and streamlines audit processes.Q: What safety features are included to ensure reliable operation?

A: The equipment meets EN 61010-1 safety standards and features built-in audible and visual alarms. These alerts promptly notify users of any irregularities during testing, reducing risk and ensuring operator and product safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese