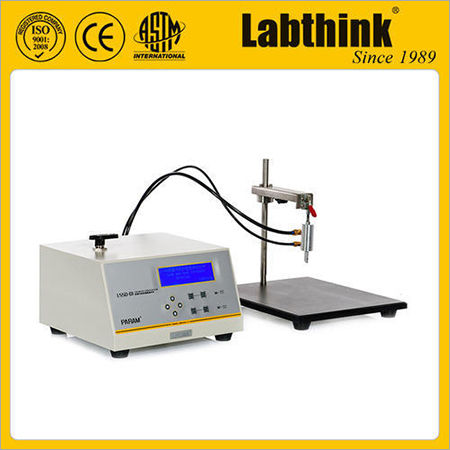

Vacuum Leak Testing Machine

2000.00 - 20000.00 USD ($)/Set

Product Details:

- Input Compressed Air / Vacuum source

- Output Pass/Fail indication with buzzer

- Product Type Vacuum Leak Testing Machine

- Usage Testing leak integrity of packaging and components

- Efficiency High sensitivity leakage detection

- Standard ISO 9001:2015

- Insulation Material Acrylic/Polycarbonate chamber

- Click to View more

X

Vacuum Leak Testing Machine Price And Quantity

- 1 Set

- 2000.00 - 20000.00 USD ($)/Set

Vacuum Leak Testing Machine Product Specifications

- Testing leak integrity of packaging and components

- Gray/Transparent

- ISO 9001:2015

- Digital Touch/Manual

- Compressed Air / Vacuum source

- 230V AC, 50 Hz, Single Phase

- 230V

- Approx. 450 x 350 x 400 mm (Standard)

- High sensitivity leakage detection

- Vacuum Leak Testing Machine

- Customizable chamber sizes

- Up to 1% of set value

- 22 kg (approx.)

- Acrylic/Polycarbonate chamber

- Pass/Fail indication with buzzer

- Manual/Automatic lid operation

Vacuum Leak Testing Machine Trade Information

- 10 Set Per Week

- 7 Days

Product Description

Product Details:

| Operation | Automatic |

| Certifications | ISO 9001, Ce |

Technical Specifications

- Vacuum degree: 0~-90kpa

- Accuracy: 1% of FS

- Vacuum Chamber Size:270 mm x 210 mm (H) customization is available for other sizes

Advanced Leak Testing for Multiple Applications

Designed for the accurate assessment of packaging and component integrity, this machine employs digital pressure monitoring and robust chamber materials to guarantee reliable results. Suitable for pharmaceutical, food, and industrial sectors, it assures compliance, quality and safety through high sensitivity detection and strict adherence to ISO 9001:2015 standards.

User-Oriented Controls and Flexible Operation

The Vacuum Leak Testing Machine offers both digital touch and manual control options, allowing operators to select their preferred method. Adjustable cycle times (10999 seconds), pass/fail output with buzzer alarms, and manual or automatic lid operation make testing seamless and versatile in diverse settings.

Reliable Safety and Data Management Features

Equipped with overpressure protection, auto-release mechanisms, and data logging via USB or printer, the machine ensures both operator safety and effortless record-keeping. Its quiet operation and customizable chamber size further enhance laboratory and production workflows.

FAQs of Vacuum Leak Testing Machine:

Q: How is vacuum leak testing performed using this machine?

A: The process involves placing the sample inside the high-grade acrylic or stainless steel chamber, sealing it with a silicone rubber gasket, and applying a controlled vacuum (0 to -700 mmHg) via compressed air or external vacuum source. The cycle time is adjustable, and results are indicated by the digital pressure gauge/LCD display, with pass/fail outputs and buzzer alerts.Q: What types of samples and packaging can be tested for leaks?

A: This machine is suitable for testing a wide range of packaging materials, medical devices, food containers, and critical components. Customizable chamber dimensions and various sample holders accommodate different sizes and shapes, making it adaptable for diverse testing requirements.Q: When should the vacuum leak testing machine be used in the inspection process?

A: It is recommended to use this machine during quality control stages, especially before product dispatch or after packaging to verify seal integrity, compliance with standards, and to prevent defective shipments. Routine testing also ensures ongoing quality and safety in production environments.Q: Where can the vacuum leak testing machine be installed and operated?

A: Due to its compact size (approx. 450 x 350 x 400 mm) and quiet operation (<60 dB), it is ideal for laboratory benchtops, factory floors, and quality assurance departments in various industries including pharmaceuticals, food, and manufacturing.Q: What is the benefit of adjustable cycle time and data logging?

A: Adjustable cycle times (10 to 999 seconds) provide flexibility for different sample requirements and process optimization. Optional data logging via USB or printer interface enables tracking, analysis, and easy documentation of each test, supporting compliance and quality audits.Q: How does the machine ensure safety during operation?

A: Integrated overpressure protection and automatic vacuum release mechanisms protect operators and samples. The sturdy chamber construction and insulation materials (acrylic/polycarbonate) further enhance safety and durability during repeated usage.Q: What makes this vacuum leak tester efficient for high sensitivity leak detection?

A: It achieves leak detection accuracy up to 1% of the set value with advanced digital pressure controls and high-quality sealing. The rapid test cycle, customizable chamber, and integrated output indicators ensure efficient and reliable testing for even the smallest leaks.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Seal Strength Testing Machine' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese