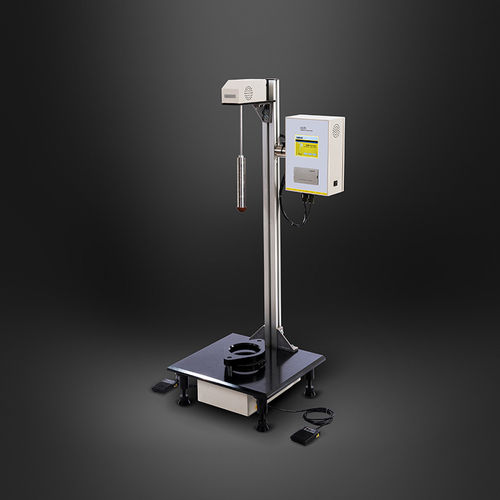

Drop Hammer impact testing apparatus for Plastic Films

Product Details:

- Temperature 10C - 40C operating

- Operating Voltage 220V10%, 50Hz

- Measuring Range 0.1 J 50 J

- Test Range 0.1 J 50 J

- Application Impact resistance testing of plastic films

- Features Interchangeable hammer weights, adjustable drop height, safety shield, easy specimen mounting

- Interface Type RS232/USB (optional)

- Click to View more

Drop Hammer impact testing apparatus for Plastic Films Price And Quantity

- 1 Set

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

Drop Hammer impact testing apparatus for Plastic Films Product Specifications

- RS232/USB (optional)

- Interchangeable hammer weights, adjustable drop height, safety shield, easy specimen mounting

- 0.1 J 50 J

- Up to 300 mm

- Impact resistance testing of plastic films

- 0.1 J 50 J

- Up to 2 kg drop weight

- 10C - 40C operating

- 220V10%, 50Hz

- 220V AC, 50 Hz

- Up to 85% RH

- 1% of full scale

- 0 - 1000 mm (adjustable)

- Free fall (Gravity-driven)

- Digital LCD display

- 1 per cycle

- Floor standing

- Standard 8 mm pneumatic

- 150 mm 150 mm (customizable)

- 0.01 J

- Drop Hammer Impact Tester

- 1000 mm drop height

- Hammer head: HRC 602

- Semi-automatic

- <1 sec

- Manual and pneumatic control

- Laboratory and industrial testing

- 0.6 MPa (compressed air required)

- Approx. 40 kg

- Single impact per operation

Product Description

Product Features Notes1

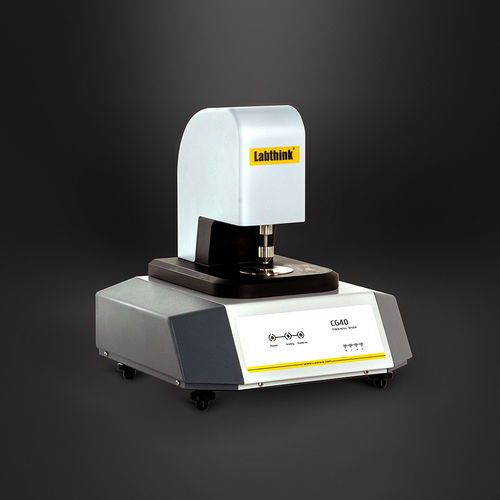

- Menu interface, color touch screen operation, convenient and fast to set test parameters.

- Two test modes A and B are provided, and the test status is automatically judged.

- The falling dart adopts the principle of electromagnetic hanging, which can release automatically, effectively avoiding the system error caused by human factors.

- Pneumatic sample clamping, manual and pedal dual start mode, built-in observation lamp unique design; convenient, fast and accurate operation.

- Professional computer software supports the functions of multi unit display of test results, graphic display of test process, output and print function, showing the results clearly and intuitively.

- Micro printer and standard RS232 interface make the tester convenient for the external connection and data transmission between the system and the computer.

Testing Principle

At the beginning of the test, select the test method as the first procedure, estimate an initial mass and 3m value, and conduct the test. If the first sample is damaged, the weight 3m shall be used to reduce the falling mass; if the first sample is not broken, the weight 3m shall be used to increase the falling mass for test in turn. In short, the use of weights to reduce or increase the falling mass depends on whether the previous sample is damaged. After 20 samples are tested, the total number of damaged samples is calculated. If n is equal to 10, the test is completed; if n is less than 10, continue the test after supplementing samples until n is equal to 10; if n is greater than 10, continue testing after supplementing samples until the total number of undamaged samples is equal to 10. Finally, the system automatically calculates the impact results.

Reference Standard Note 1

ISO 7765-1-1988, ASTM D1709, GB/T 9639.1-2008, JIS K7124-1

Test Applications

| Basic Applications |

|---|

|

|

|

| Extended Applications |

|

|

Technical Parameters Note 2

| Items | Parameters |

|---|---|

| Measuring Method | Method A, method B(optional) |

| Test Scope | Method A: 50-2000g Method B: 300-2000g |

| Weight Accuracy | +0.5% |

| Sample Clamping | Pneumatic |

| Air Source Pressure | 0.6 MPa (Prepared by user) |

| Air Connection | I 8 mm polyurethane pipe |

| Sample Size | >150 mm x 150 mm |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Net Weight | 70 kg |

| Dimensions | Amethod:500 mm (L) 450 mm (W) 1320 mm (H) |

| Method B: 500 mm (L) 450 mm (W) 2160 mm (H) |

Product Configuration Note 1

| Standard Configuration | A method configuration, touch screen, micro printer |

|---|---|

| Options | Method B configuration, professional software and communication cable |

| Remarks | The air source interface of the machine is I 8 mm polyurethane pipe; the air source is provided by the user |

Note 1: The product functions, reference standards and configuration information are subject to the specific marks in the "technical indicators".

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory according to the requirements and conditions of relevant laboratory environmental standards.

Accurate Impact Testing for Plastic Films

This apparatus delivers consistent and accurate measurements of impact resistance for plastic films using gravity-driven free-fall hammers and advanced sensors. Its compliance with ASTM D1709 and IS 2508 assures reliable, industry-standard results. Its robust construction and digital display provide ease of use and clear data interpretation, making it ideal for quality control in both laboratory and manufacturing environments.

Flexible and User-Friendly Design

With interchangeable hammer weights ranging from 300 g to 2,000 g and an adjustable drop height (up to 1,000 mm), users can tailor tests to specific film types and thicknesses. The pneumatic clamping system ensures secure specimen hold, while the intuitive manual and pneumatic controls simplify operation. The internal memory, storing up to 50 results, streamlines data management and reporting.

Enhanced Safety and Durability

Equipped with a powder-coated body, corrosion-resistant stainless steel impact plate, and a reliable guard with interlock safety mechanism, this impact tester emphasizes operator protection and long service life (>10,000 cycles). Its quiet operation (<65 dB), along with rigorous design for vibration-free installation, makes it a safe and durable addition to any test facility.

FAQ's of Drop Hammer impact testing apparatus for Plastic Films:

Q: How does the Drop Hammer Impact Tester measure the impact resistance of plastic films?

A: This tester operates using a gravity-driven free-fall hammer that impacts the secured film specimen, measuring the energy absorbed during the fracture. The adjustable hammer mass and drop height allow for precise calibration according to specific testing needs, and results are displayed instantly on a digital LCD.Q: What are the benefits of using interchangeable hammer weights for testing plastic films?

A: Interchangeable hammer weights (from 300 g to 2,000 g) enable a broad range of impact energies (0.1 J-50 J), allowing accurate simulation of various real-world conditions and compliance with different industry standards, thus improving the versatility and reliability of your testing process.Q: When should the calibration kit be used with the apparatus?

A: The certified calibration kit included with the tester should be used during initial setup and routine maintenance, typically before critical test sessions or at regular intervals, to ensure the ongoing accuracy of impact energy measurements and maintain compliance with ASTM and IS standards.Q: Where is this apparatus best installed and used?

A: The equipment is designed for installation in laboratory or industrial environments on a vibration-free, level surface, away from direct sunlight. Operating in controlled ambient conditions (10C-40C, up to 85% RH) will maximize precision and device longevity.Q: What is the process for conducting an impact test on plastic films?

A: First, mount the specimen (typically 150 mm 150 mm) securely using the pneumatic clamping system. Select the desired hammer mass and adjust the drop height. Once safety interlocks are confirmed, release the hammer for a single impact. The apparatus records the result, which can be reviewed immediately or stored for future reference.Q: How does the safety mechanism ensure operator protection during tests?

A: A mechanically robust guard with an interlock system prevents the operation when the cover is open, significantly reducing the risk of accidental contact with moving parts. This ensures safe testing and compliance with standard laboratory safety protocols.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese