Testing Barrier Properties of Multi-Layer Packaging Films

Product Details:

- Accuracy 1% FS

- Temperature 15C - 50C

- Measuring Range 0.01 - 500 cm/m24h0.1MPa

- Gas Pressure 0.6 MPa

- Automation Grade Automatic

- Resolution 0.001 cm/m24h0.1MPa

- Test Range 0.01 - 500 cm/m24h0.1MPa

- Click to View more

Testing Barrier Properties of Multi-Layer Packaging Films Price And Quantity

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

- 1 Set

Testing Barrier Properties of Multi-Layer Packaging Films Product Specifications

- Automatic

- 0.6 MPa

- 0.01 - 500 cm/m24h0.1MPa

- 15C - 50C

- 1% FS

- 30 mm

- 1 - 3

- 350 mm

- 0.01 - 500 cm/m24h0.1MPa

- Barrier Property Testing of Multi-Layer Packaging Films

- Approx. 60 kg

- 0.001 cm/m24h0.1MPa

- 0.1 - 10 mm/min

- 100 mm x 100 mm

- AC 220V, 50Hz

- LCD Digital Display

- Tabletop

- Laboratory Analysis/Quality Control

- Automatic Temperature and Humidity Control, Multi-style Data Storage, Real-time Data Display

- Standard Gas Inlet (6 mm OD)

- Microcomputer Controlled

- 20% - 90% RH

- Film Barrier Property Tester

- 220V AC

- 50 N

- RS232

- 70 mm

- 50 Hz

- 10 s

Product Description

Product Featuresnote1

OTR/WVTR tested in One Instrument

- OTR WVTR mode, OTR mode and WVTR mode are available for selection.

- OTR and WVTR tests can be automatically completed for each sample mounting.

- Genuinely reflect the OTR WVTR performance of the same sample, avoiding effect on test data due to sample contamination arising from instrument switching.

Coulometric Oxygen Sensor

- The instrument is equipped with a ppb level Coulometric Oxygen Sensor, as one of new Labthink technical achievements, which can obtain a lower limit of the test.

- Designed according to ASTM D3985 with absolute value, and no calibration is permitted.

- Longer service life, two times longer than that of a traditional Coulometric oxygen sensor.

- Over limit alarm and automatic protection.

Infrared Moisture Sensor

- The instrument is equipped with Labthink patented infrared moisture sensor which can obtain a lower limit of the test.

- Designed according to ASTM F1249.

- Longer service life, non-consumable.

- Over limit alarm and automatic protection.

Accurate Data

- Brand new rainbow bridge structural test cell and 360 air circulation constant temperature technology ensure better temperature stability.

- In the test process, the automatic control on flow, temperature and relative humidity is realized, reaching higher accuracy.

- The test cell is equipped with a high-precision humidity sensor to monitor and record humidity changes in real time.

High Efficiency 6 Test Cells

- Independent six sets of 50cm2 standard area test cells, which is three times the traditional oxygen transmission rate test instrument.

- Six samples can be tested at the same time under the same conditions, with independent tests data.

- In the same test cycle, the number of samples completed increases from 2 to 6.

- Automatic sample clamping, saving time and effort, ensuring consistent clamping force and better sealing.

Intelligent Operation

- The 12 Inch Touch panel of windows system is used for more convenient operation.

- Automatic mode - after inputting test temperature and humidity and clicking one key, the test proceeds automatically.

- Intelligent test cell hood which opens and closes automatically with sound and light alert.

Safe and Reliable

- Safe Running: Labthinks high-end industrial computer is embedded to eliminate the system failure caused by computer virus and ensure the operation reliability and data storage security.

- Safe Operation: equipped with optical and other intelligent sensors as well as intelligent sound and light alarms to ensure the operation safety.

- Safe Performance: the instrument uses global renowned brand components with stable and reliable performance.

Space Saving

- The width of the instrument is only 1/3 of the traditional six-cell instrument, saving laboratory space.

Powerful Functions

- Professional test mode provides flexible and plentiful control functions to meet the needs of scientific research.

- Display oxygen/water vapor transmission rate curve, oxygen/water vapor transmission coefficient curve, temperature curve and humidity curve.

- Wide temperature range, allowing the barrier test at different temperatures (customized).

- The gas purification device independently developed by Labthink can remove trace oxygen in nitrogen, providing oxygen-free carrier gas (optional).

Testing Principle

The pre-treated sample is clamped between the test chambers, oxygen or nitrogen with stable relative humidity flows on one side of the film, and the high purity nitrogen flows on the other side; oxygen or water molecules diffuse through the film into high-purity nitrogen on the other side, and are carried to the sensor by the flowing nitrogen. By analyzing the oxygen or water vapor concentration measured by the sensor, the oxygen or water vapor transmission rate can be calculated.

Reference Standards

ASTM D3985, ASTM F1307, GB/T 19789, GB/T 31354, DIN 53380-3, JIS K7126-2-B, YBB 00082003-2015

ASTM F1249, ISO 15106-2, GB/T 26253, JIS K7129, YBB00092003-2015

Test Applications

| Applications |

|---|

|

|

Technical Specifications

Table 1: Test Parameters Note2

| Parameter/Model | Model C406H | |

|---|---|---|

| OTR Test Range | cc/(m2day) (Standard area 50cm2) | 0.02 200 |

| cc/(m2day) (MASK area 1cm2) | 1 10000 (Optional) | |

| cc/(m2day) (MASK area 5cm2) | 0.2 2000 (Optional) | |

| OTR Resolution | cc/(m2day) | 0.0001 |

| OTR Repeatability | cc/(m2day) | 0.02 or 1%, whichever is greater |

| WVTR Test Range | g/(m2day) (Standard area 50cm2) | 0.02 40 |

| g/(m2day) (MASK area 5cm2) | 0.2 400 (Optional) | |

| g/(m2day) (MASK area 1cm2) | 1 2000 (Optional) | |

| WVTR Resolution | g/(m2day) | 0.0001 |

| WVTR Repeatability | g/(m2day) | 0.02 or 2%, whichever is greater |

| Temperature range | C | 15 - 50 5 60 (Customized) |

| Temperature fluctuation | C | 0.15 |

| Humidity range | %RH (Within standard temperature range) | 0%, 5 - 902%, 100% |

| Extended functions | GP-01 Gas Purification Unit | Optional |

| DataShieldTM Note3 | Optional | |

| Computer System required by GMP | Optional | |

| CFR21 Part11 | Optional | |

Table 2: Technical Specifications

| Test Chamber | 6 test chambers |

| Specimen Size | 4.6 x 4.6i1411.7cm11.7cm) |

| Specimen Thickness | 120 Mili143mmi14 |

| Standard Test Area | 50 cm2 |

| Carrier Gas | 99.999% high purity nitrogen, 99.5% oxygen (gas source is out of supply scope) |

| Carrier Gas Pressure | 40.6 PSI / 280 kPa |

| Port Size | 1/8 inch metal tubing |

| Power Supply | 120VAC10% 60Hz / 220VAC10% 50Hzi14either one of twoi14 |

| Instrument Dimensions | 23.6 H x 19.2 W x 25.9 D (60cm 49cm 66cm) |

| Net weight | 220Lbsi14100kgi14 |

Configurations

- Standard Configurations

- Mainframe, tablet, sampler, vacuum grease, polyurethane pipe of 6 mm in diameter

- Optional Parts

- GP-01 Gas Purification Unit, air compressor, CFR21Part11, GMP computer system requirements and DataShieldTM Data ShieldNote3

- Remarks

- 1. The gas supply port of the instrument isI 6 mm polyurethane pipe (pressure 79.7 psi / 550 kPa);

2. Customers will need to prepare for gas supply and distilled water.

Note 1: All the product features are subject to detailed descriptions in the "Technical Parameters.

Note 2: The parameters in the table are measured by professional operators in Labthink Laboratory according to the requirements and conditions of relevant laboratory environmental standards.

Note 3: DataShieldTM Data Shield System provides safe and reliable data application support. The system can be shared by multiple Labthink products. Please purchase separately as needed.

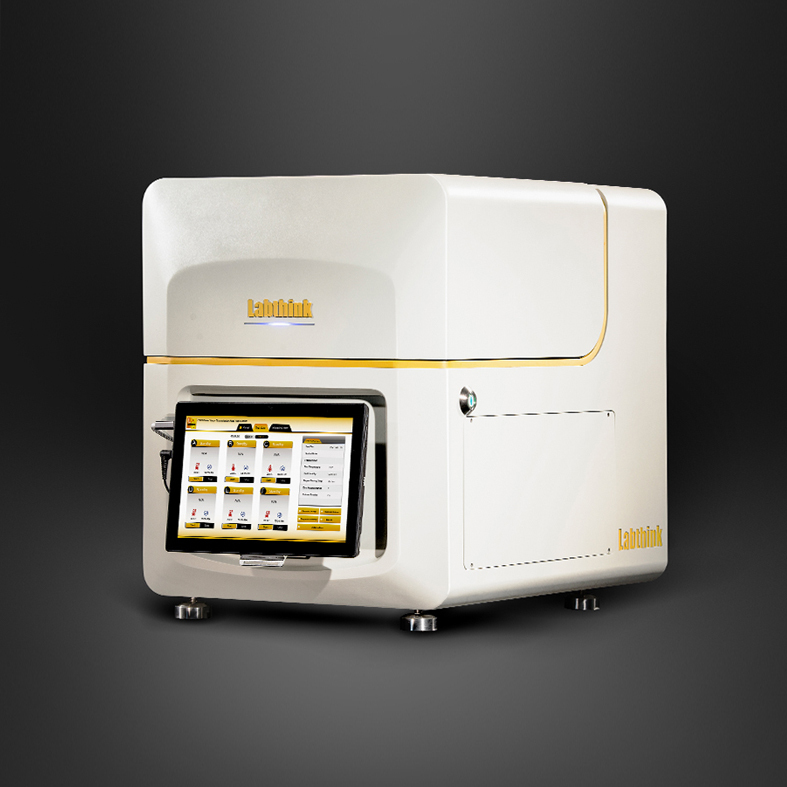

Versatile Barrier Testing for Films

Specially engineered for rigorous barrier property evaluation, this tester accommodates various multi-layer films. Its measuring range and high sensitivity (accuracy 1% FS, resolution 0.001 cm3/m224h0.1MPa) ensure reliability across research, development, and quality control applications. Support for up to three specimens enhances productivity and comparative analysis.

User-Friendly Design and Smart Features

The barrier tester boasts a clear LCD digital display, adjustable test speeds, and intuitive controls for an efficient testing experience. Automatic calibration and multi-style data storage streamline workflows, while the tabletop mounting and compact design (approx. 60 kg) fit seamlessly into most laboratories, reducing operational noise to a pleasant 60 dB.

Powerful Software and Data Management

Equipped with dedicated analysis software, the tester enables real-time monitoring, easy data extraction (USB/Ethernet, RS232), and storage of up to 10,000 test results. Automatic temperature and humidity control ensure consistency, supporting traceable compliance with international standards for barrier property testing.

FAQ's of Testing Barrier Properties of Multi-Layer Packaging Films:

Q: How does the coulometric sensor method work in testing barrier properties of films?

A: The coulometric sensor method measures the passage of gases through multi-layer packaging films, providing highly accurate quantification of barrier properties. By monitoring the amount of gas that penetrates the film over a controlled area and time, the system delivers precise results, making it ideal for assessing oxygen transmission as per ASTM D3985 and ISO 15105-2.Q: What types of samples and environments are suitable for this barrier tester?

A: This barrier property tester is suitable for multi-layer packaging films with specimen sizes of 100 mm x 100 mm and a test width of up to 30 mm. It operates effectively both in clean rooms and standard laboratory environments, with ambient conditions ranging from 20%-90% RH humidity and 15C to 50C temperature.Q: When should samples be conditioned before testing, and why is it important?

A: Samples should undergo conditioning for 30 minutes to 24 hours prior to testing to achieve equilibrium with ambient laboratory conditions. Proper conditioning ensures reliable and reproducible barrier property data, minimizing errors from moisture or temperature variations.Q: What is the process for conducting a test using this equipment?

A: To test a film, specimens are placed in the chamber, then conditioned as required. Parameters are set using the microcomputer control, followed by automatic calibration. The system monitors gas transmission, and results are displayed in real-time on the LCD display, with data exportable via USB or Ethernet for further analysis.Q: Where are the test data stored and how can they be accessed?

A: The device features built-in memory capable of storing up to 10,000 test results. Data can be accessed directly from the instrument via its analysis software and exported through USB, Ethernet, or RS232 interfaces, facilitating easy sharing and reporting for quality control documentation.Q: How does this tester benefit laboratory analysis and quality control workflows?

A: By offering automatic calibration, high-resolution measurements, rapid response, and dedicated software, the tester improves productivity and accuracy in laboratory settings. Support for multiple specimens and compliance with industry standards allow for robust, automated, and standardized barrier property assessments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'OTR/WVTR Test System' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese