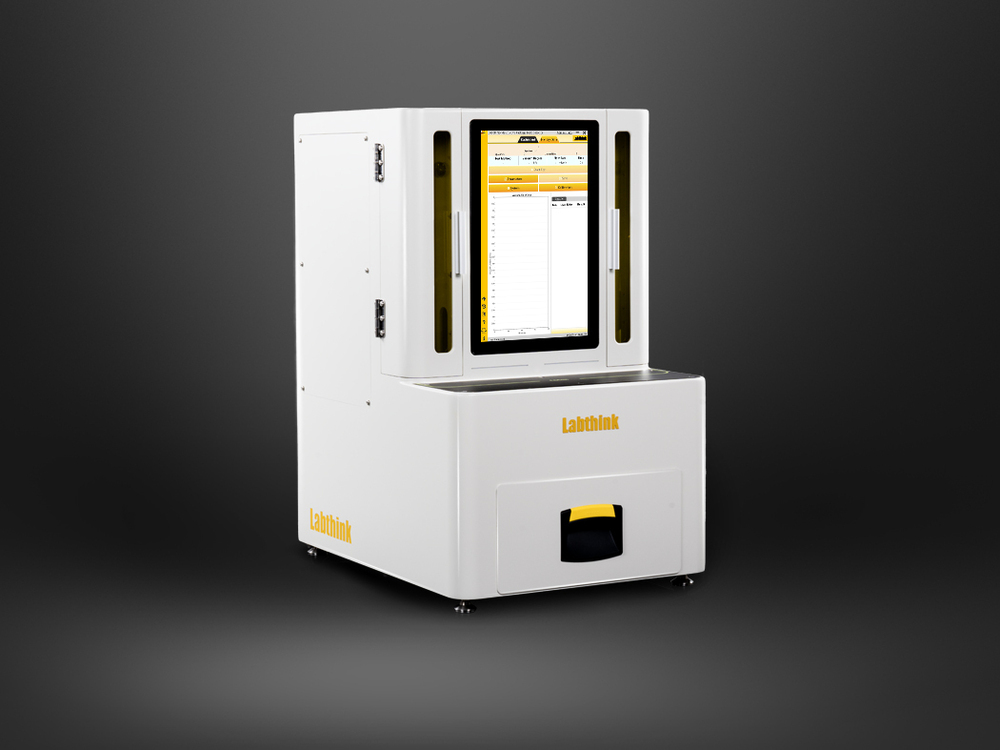

Vacuum Leak Tester for PET bottles

Product Details:

- Gas Pressure Adjustable vacuum pressure up to 900 mbar

- Sensor Integrated vacuum pressure sensor

- Specimen Size 250 ml to 2 L PET bottles

- Operating Temperature 5C to 45C

- Accuracy +/- 1% of full scale

- Power Supply AC mains

- Display Digital LED

- Click to View more

Vacuum Leak Tester for PET bottles Price And Quantity

- 50000 USD ($)/Set

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

Vacuum Leak Tester for PET bottles Product Specifications

- 5C to 45C

- +/- 1% of full scale

- Air/Vacuum

- 1 (single bottle per test)

- 220V AC, 50Hz

- Suitable for PET bottle base up to 150mm diameter

- Integrated vacuum pressure sensor

- Adjustable vacuum pressure up to 900 mbar

- 250 ml to 2 L PET bottles

- Standard fitting for PET bottles (compliant with various neck sizes)

- PET bottles

- To detect leaks in PET bottles by vacuum testing method

- < 5 seconds

- Stainless Steel

- 5C to 45C (Operating)

- Digital LED

- 0 - 900 mbar

- AC mains

- Manual Operation

- Up to 80% RH, non-condensing

- 7.5 kg

- Bench-top

Product Description

Product FeaturesNote1

Multiple Test Modes & Intelligent Statistics of Qualified Specimens

- Negative pressure method

- Multiple test modes including standard, multi-grade vacuum and methylthionine chloride mode

- Automatic test with traditional methylthionine chloride

- Vacuum degree, test time and infiltration time can be adjusted and test parameters can be saved automatically so that the tests with same test parameters can be started quickly

- Automatic constant pressure compensation ensures that the tests can be performed under preset vacuum conditions

- Real-time display of test curves, easy to observe the test results

- Automatic statistics of qualified specimens

- Main components and parts are supplied by well-known global manufacturers, with guaranteed performance

Brand New Patented Intelligent Touch Operating System

- Industrial grade touch screen, one-button operation, simplified operating interface, remote upgrade and maintenance

- Chinese and English operating interface

- Measurement unit conversion

- Automatic data storage and power failure memory to prevent data loss

- Storage up to 1200 test records (standard mode)

- Multiple-level user management and login with password

- Micro-printer and USB ports for data transmission (optional)

- The instrument conforms to the requirements of GMP (optional)

- Labthinks unique DataShiledTM System for data management and connecting with information system (optional)

Test Principle

Firstly submerge the specimen in the water in the vacuum chamber, and then evacuate the vacuum chamber to form differential pressure between the inside and outside of specimen. The seal property can be obtained by observing the steady progression of bubbles from the specimen or observing how the specimen expands and restores to its original shape after vacuum release.

Test StandardNote1

ASTM D3078, GB/T 15171

Applications

| Basic Applications |

|---|

|

|

|

|

| Extended Applications |

|

|

|

Technical Specifications

| Specifications | C660B |

|---|---|

| Vacuum Degree | 0 -90 KPa/ 0 -13 psi |

| Accuracy | 0.25% FS |

| Resolution | 0.1 KPa / 0.01 psi |

| Vacuum Chamber Effective Sizes |

I270 mm x 210 mm (H) (standard) |

| I360 mm x 585 mm (H) (optional) | |

| I460 mm x 330 mm (H) (optional) | |

| Note: customization is available for other sizes | |

| Gas Supply | Air (outside of supply scope) |

| Gas Supply Pressure | 0.5 MPa 0.7 Mpa (73psi 101psi) |

| Instrument Dimension | 334 mm (L) x 230 mm (W) x 170 mm (H) |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Net Weight | Instrument: 6.5 kg Standard Vacuum Chamber: 9kg |

Configurations

- Standard Configurations

- Instrument, Standard Vacuum Chamber (I270 mm x 210 mm), I6 PU Tubing (1m)

- Optional Parts

- Micro Printer, Professional Software, Customized Vacuum Chamber, Air Compressor, GMP System, DataShieldTM Note3

- Note

- 1. The gas supply port of the instrument isI6 mm PU Tubing;

2. Customers need to prepare gas supply.

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

Precise Leak Testing for PET Bottles

The vacuum leak tester facilitates accurate detection of leaks in PET bottles by employing a pressure drop monitoring system. It is compatible with a wide range of bottle types and sizes, ensuring versatility in bottling facilities. The transparent chamber and durable materials make observation easy and improve safety during testing.

Simple Operation and Maintenance

With its start/stop push button controls and selectable cycle times, the tester offers straightforward manual operation. The built-in oil-free vacuum pump ensures reliability with minimal maintenance, while accessible internal components simplify any service needs. On-site and remote support options are available for customer convenience.

Safety and Compliance Assurance

Safety is prioritized through automatic pressure relief and over-pressure protection, combined with robust construction. Factory calibration and external re-calibration ports guarantee ongoing accuracy, while CE marking and ISO 9001 certification provide added peace of mind for global markets.

FAQ's of Vacuum Leak Tester for PET bottles:

Q: How does the vacuum leak tester identify leaks in PET bottles?

A: The tester uses a vacuum pressure drop monitoring technique to detect leaks. When a PET bottle is placed in the chamber, a vacuum is created, and the unit measures any pressure changes. If a significant pressure drop is detected, it indicates the presence of a leak.Q: What types and sizes of PET bottles can be tested with this device?

A: The tester is designed for single-bottle testing of PET water, carbonated soft drink, and edible oil bottles. It accommodates bottles between 250 ml and 2 L with a base diameter up to 150 mm, ensuring compatibility with most standard PET bottle sizes.Q: How is the leak test performed using this bench-top tester?

A: Simply position a PET bottle in the chamber, close the transparent lid, select the desired test cycle time (typically between 10-60 seconds), and press the start button. The unit automatically runs the vacuum test, visually and audibly alerting the user to any detected leaks.Q: When should the tester be recalibrated, and how is this done?

A: Though the tester comes factory-calibrated, periodic recalibration is recommended as per your quality protocol or after significant service. The external calibration port allows for straightforward recalibration using standard pressure calibration equipment.Q: Where can this vacuum leak tester be installed and used?

A: Thanks to its compact table-top design and plug-and-play setup, the tester is suitable for laboratories, quality control rooms, and production areas. It only requires a standard 220V AC power supply and operates efficiently in environments with temperatures from 5C to 45C and up to 80% relative humidity.Q: What maintenance is required for the vacuum leak tester?

A: Minimal maintenance is needed due to the oil-free diaphragm pump and accessible internal components. Regular checks on the chamber, seals, and pump are sufficient for optimal operation. The robust stainless steel construction also aids in longevity.Q: What are the main benefits of using this vacuum leak tester for PET bottles?

A: Using this tester ensures reliable detection of leaks, reduces the risk of product recalls, and maintains product quality. It features fast response times, high accuracy, comprehensive safety mechanisms, user-friendly controls, and low maintenance, making it an effective and valuable tool for bottle manufacturers and exporters.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Leak and Integrity Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese