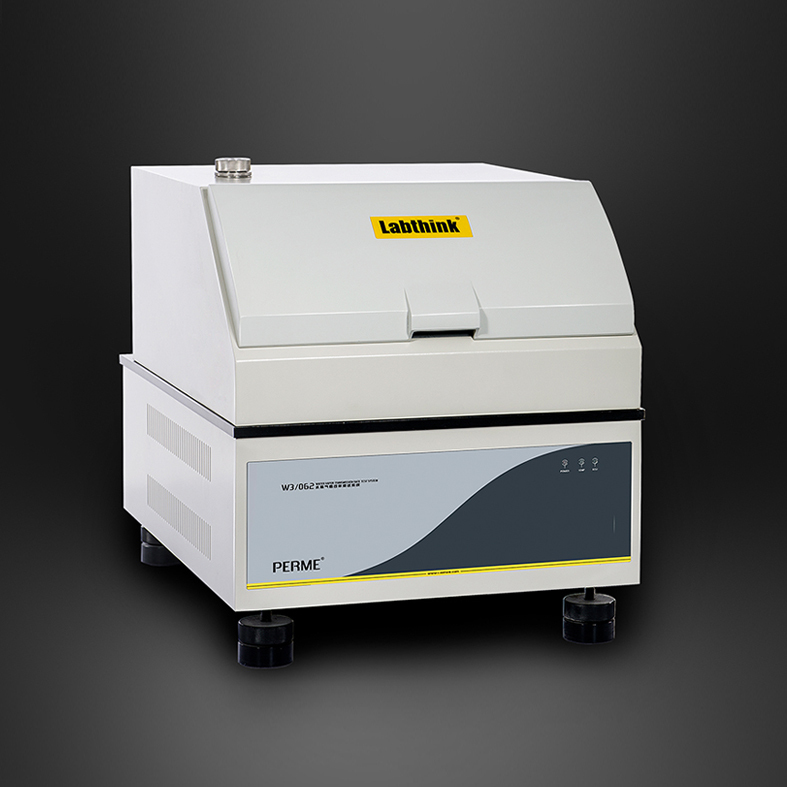

Cup Method Leather Water Vapor Permeability Testing

Product Details:

- Measuring Range 09999 g/m24h

- Display Type Analog

- Frequency Manual, according to test requirements

- Test Range 05000 g/m24h

- Specimen Size 33 mm

- Humidity 40%90% RH (adjustable)

- Temperature Room Temperature or as specified

- Click to View more

Cup Method Leather Water Vapor Permeability Testing Price And Quantity

- 1 Set

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

Cup Method Leather Water Vapor Permeability Testing Product Specifications

- 220V AC

- 400 mm

- Simultaneous multi-cup testing, simple operation

- 05000 g/m24h

- 20 mm

- Analog

- 09999 g/m24h

- Manual, according to test requirements

- Manual

- Immediate after manual weight change

- Leather Water Vapor Permeability Tester

- 6 cups/specimens

- 40%90% RH (adjustable)

- Room Temperature or as specified

- Laboratory quality control and research

- 33 mm

- Standard cup opening (customizable)

- 90 cycles/min

- Manual

- 1 g/m24h

- Benchtop

- 220V, 50Hz

- 35 kg

- Water vapor permeability testing of leather and synthetic materials

- 70 mm

- 0.01 g

- 6 specimens per test

Product Description

Principle

Under a certain test temperature, a constant humidity difference is generated between two sides of the test specimen. The water vapor permeates through the specimen and into the dry side. By measuring the weight changes of the test dish in different time, water vapor transmission rate and other parameters can be obtained.

Standards

This test instrument conforms to the following standards:

ISO 2528, GB 1037, GB/T 16928, ASTM E96, ASTM D1653, TAPPI T464, DIN 53122-1, JIS Z0208, YBB 00092003

Applications

This instrument is applicable to the determination of water vapor transmission rate of:

| Basic Applications |

|---|

|

|

|

|

| Extended Applications |

|

|

|

|

|

|

|

Technical Specifications

| Specifications | Film Test |

|---|---|

| Test Range | 0.110,000 g/m224h (Water Method) 0.12,500 g/m224h (Desiccant Method) |

| Number of Specimens | 16 with independent test results |

| Accuracy | 0.01 g/m224h |

| Resolution | 0.001 g (Customization Available) |

| Temperature Range | 15C55C (standard) |

| Temperature Accuracy | 0.1C(standard) |

| Humidity Range | Water Method: 90%RH 70%RH Note1 |

| Desiccant Method: 10%RH98%RH Note2 | |

| Humidity Accuracy | 1%RH |

| Air Velocity | 0.52.5 m/s (customization available) |

| Specimen Thickness | 3 mm (customization is available for other thickness) |

| Test Area | 33 cm2 |

| Specimen Size | I74 mm |

| Test Chamber Size | 45 L |

| Gas Supply | Air |

| Gas Supply Pressure | 0.6 MPa |

| Port Size | I6 mm PU tubing |

| Instrument Dimension | 660 mm (L) x 580 mm (W) x 580 mm (H) |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Net Weight | 80 kg |

Note1: Herein the "Humidity means the humidity difference between the two sides of the film specimen. The humidity in the test chamber is 10%30%RH accordingly.

Note2: Herein the "Humidity means the humidity difference between the two sides of the film specimen. The humidity in the test chamber is 10%RH-98%RH when the temperature is 15 to 40 C, 10%RH-90%RH when the temperature is 45 C, 10%RH-80%RH when the temperature is 50 C, 10%RH-70%RH when the temperature is 55 C.

Configurations

- Standard Configurations

- Instrument, Professional Software, Test Dishes, Desiccant Tube, Humidity Generator, Calibration Weight, Communication Cable, Round Sample Cutter and Valve Set

- Optional Parts

- Satellite Base, Reference Film, Air compressor and Desiccant

- Note

- 1. The gas supply port of the instrument is I6 mm PU tubing;

2. Customers will need to prepare for gas supply and distilled water.

Precision Meets Versatility in Leather Testing

This instrument is expertly crafted for laboratories focused on quality control and research, ensuring reliable and reproducible water vapor permeability results. It supports simultaneous analysis of up to six samples, enhancing throughput and operational efficiency. With its robust stainless steel build and simple manual operation, this tester accommodates both routine and specialized testing demands on leather and synthetics.

Adherence to International Standards

Complying rigorously with ISO 14268 and GB/T 12704.1, this tester guarantees data credibility and international acceptance. Whether used by manufacturers, exporters, or research teams, its construction and measurement accuracy meet global requirements, ensuring test results can be reliably shared and benchmarked across borders.

FAQ's of Cup Method Leather Water Vapor Permeability Testing:

Q: How does the Cup Method Leather Water Vapor Permeability Tester operate?

A: The tester measures water vapor transmission by sealing leather specimens in stainless steel cups, then rotating them via a precision gear drive mechanism. The change in specimen weight-monitored either mechanically or digitally-reflects water vapor permeation over time, enabling accurate calculation of permeability.Q: What materials and specimen sizes are compatible with this tester?

A: The instrument is suitable for both leather and synthetic materials, accommodating specimens up to 33 mm in diameter. Its standard cup opening can be customized for special applications, enhancing its versatility in research and quality control environments.Q: When should this tester be used during the production process?

A: Use this equipment during quality control or research stages, typically after leather or synthetic materials are processed but before product assembly. Early testing allows for specification verification and process adjustments, ensuring product reliability and compliance with standards.Q: Where is the Leather Water Vapor Permeability Tester typically installed?

A: Designed for benchtop use, the tester should be placed in a clean, non-corrosive laboratory with controlled humidity conditions. Its compact size facilitates easy setup in research labs, manufacturing quality departments, or export inspection facilities.Q: What preparation steps are required prior to testing?

A: Sample preparation tools are included with the tester. Cut specimens to a diameter of 33 mm, mount them in the stainless steel cups, and adjust the operating environment to the required temperature and humidity. The device accommodates up to six samples per run for efficient parallel testing.Q: How does using this tester benefit manufacturers and exporters?

A: By delivering accurate and internationally recognized water vapor permeability data, this equipment helps manufacturers verify material performance and meet export or industry specifications, enhancing product quality and market acceptance.Q: What is the measurement accuracy and response time of the tester?

A: The tester achieves a high level of accuracy (1 g/m224h) with a resolution of 0.01 g. It delivers immediate results after each manual weight measurement, ensuring fast data collection and analysis.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'OTR/WVTR Test System' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese