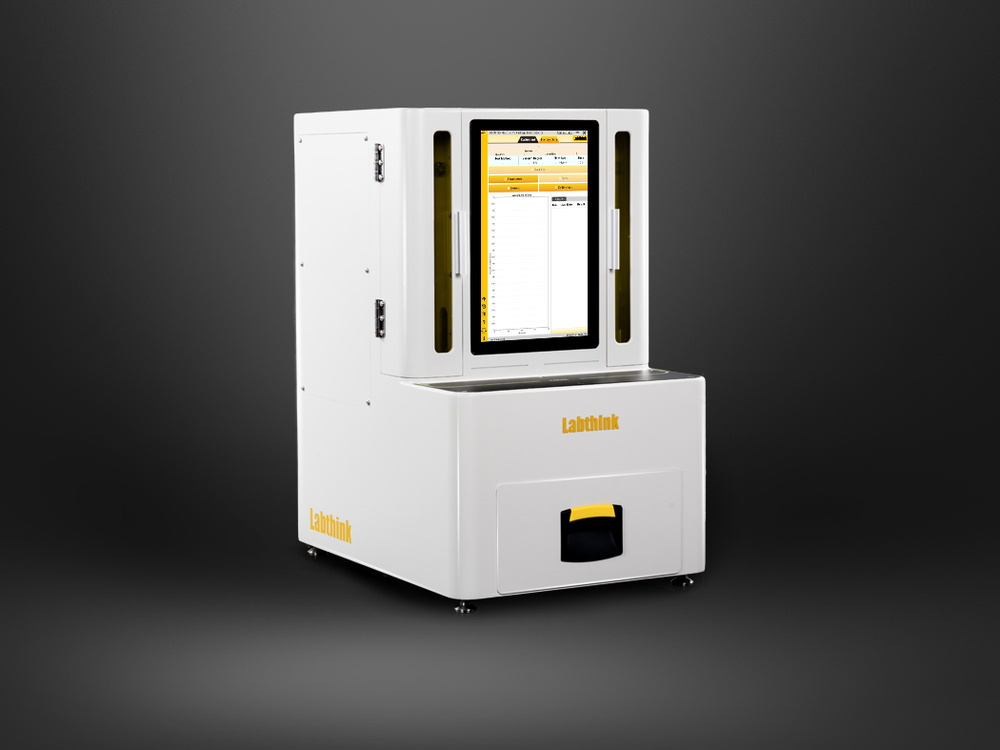

Bags Seal Leak Detection Equipment

2000.00 - 20000.00 USD ($)/Set

Product Details:

- Mounting Type Tabletop

- Equipment Type Bags Seal Leak Detection Equipment

- Hardness -

- Measuring Range 0~600 kPa

- Port Size 6 mm

- Power Supply 220V, 50Hz

- Display Type Digital LCD

- Click to View more

X

Bags Seal Leak Detection Equipment Price And Quantity

- 1 Set

- 2000.00 - 20000.00 USD ($)/Set

Bags Seal Leak Detection Equipment Product Specifications

- Seal integrity and leak detection for flexible packaging bags

- 0.1 kPa

- 0.6 MPa

- Single chamber

- Up to 300x300 mm

- Microprocessor based

- Adjustable, 10~60 cycles/min

- Approx. 25 kg

- 0~600 kPa

- Leak detection, auto alarm, real-time monitoring

- 50 Hz

- RS232/USB

- Semi-Automatic

- < 2 s

- 300 mm

- 1% F.S.

- 0~600 kPa

- 6 mm

- 0~300 mm

- 220V, 50Hz

- Tabletop

- Bags Seal Leak Detection Equipment

- -

- Up to 300 mm

- 40%~90% RH

- 220V AC

- Digital LCD

- Industrial Quality Control

- 15~40C

- Single or multiple

Bags Seal Leak Detection Equipment Trade Information

- 10 Set Per Week

- 7 Days

Product Description

Technical Specifications- Vacuum Degree: 0 ~ -90 KPa

- Accuracy: 1% FS

- Vacuum Chamber Effective Sizes: 270 mm x 210 mm (H) (standard)

- 360 mm x 585 mm (H) (optional)

- 460 mm x 330 mm (H) (optional)

- Note: customization is available for other sizes

Highly Sensitive Leak Detection

This equipment delivers exceptional leak detection performance, identifying leaks down to 0.2 mm in packaging bags. The precision is enabled by advanced testing methods and accurate digital measurement, ensuring consistent seal integrity validation for critical quality assurance processes.

Robust and Versatile Construction

Crafted from corrosion-resistant 304 stainless steel and engineered plastic, the testing system is robust enough for industrial environments. Its oil-free, maintenance-free pump suits both laboratory and production settings, handling specimen sizes up to 300x300 mm with adjustable testing parameters.

User-Friendly, Safe, and Compliant

Equipped with an intuitive LCD display and English/Chinese interface, the system streamlines operation for global teams. Safety features like overload protection and emergency stops, plus compliance with key international standards, make it a reliable choice for manufacturers, suppliers, and quality control personnel.

FAQs of Bags Seal Leak Detection Equipment:

Q: How does the Bags Seal Leak Detection Equipment identify leaks in flexible packaging?

A: The equipment uses the Vacuum Decay Method and Bubble Emission Test to pinpoint leaks. By creating a vacuum around the specimen and monitoring pressure changes or observing bubble formation, it can detect leaks as small as 0.2 mm with high accuracy.Q: What is the process for conducting a leak detection test with this machine?

A: To perform a test, place the packaging bag specimen in the chamber, set test parameters via the microprocessor display, and initiate the test. The system then performs the vacuum decay or bubble test, providing real-time results and signaling any detected leaks through audio and visual alarms.Q: Where can this leak detection equipment be used effectively?

A: This device is ideal for laboratories, manufacturing facilities, and quality assurance departments in industries involved with flexible packaging. It is suited for use in environments free of corrosive gases and where dry conditions are maintained.Q: What are the main benefits of using this leak detection equipment in industrial quality control?

A: Benefits include precise leak detection for seal integrity, compliance with international standards (ASTM F2096, ISO 11607), user-friendly controls, and digital documentation via USB or RS232 interfaces. Its fast response time and adjustable speed enhance operational efficiency.Q: When should this equipment be used during the packaging process?

A: The equipment should be used during regular quality control checks, especially after sealing processes, to ensure that all packaging meets required integrity standards before distribution or shipment.Q: What safety features are integrated into the machine?

A: The machine includes overload protection, an emergency stop switch, and both audio and visual alarms to ensure safe operation and immediate notification in case of detected faults or hazardous conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Package Leak Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese