Testing Pet Food Bags seal integrity for Freshness and Safety

Product Details:

- Test Range 0-100 N (can be customized)

- Temperature 5C-35C

- Application Testing seal integrity for pet food bags, pouches, and packaging

- Response Time <10 ms

- Power Supply AC 220V, 50Hz

- Accuracy 0.5% FS

- Gas Pressure 0-0.9 MPa

- Click to View more

Testing Pet Food Bags seal integrity for Freshness and Safety Price And Quantity

- 50000 USD ($)/Set

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

Testing Pet Food Bags seal integrity for Freshness and Safety Product Specifications

- Bench-top

- Automatic

- 0.01 - 500 mm/min (adjustable)

- 50 Hz

- 0.01 N

- Leak detection, pressure decay analysis, digital data storage, programmable operation

- 220V AC

- 0-100 N

- USB, RS232

- up to 300 mm width

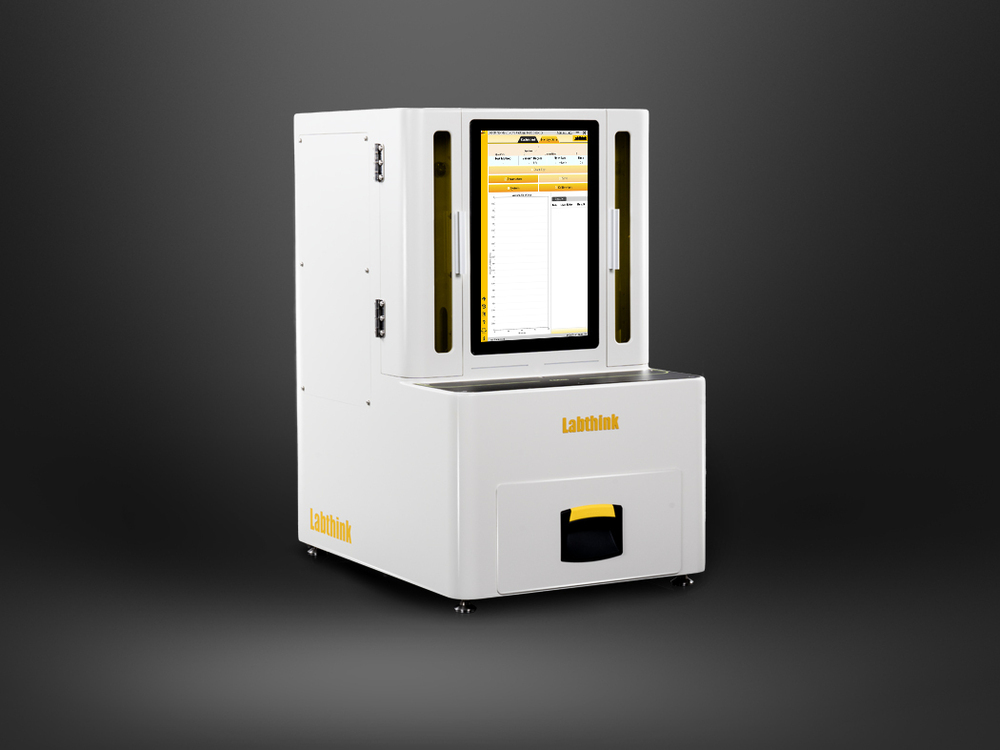

- Microcomputer control with touch screen operation

- 6 mm OD push-in fitting

- 20%-70% RH

- Digital LCD touchscreen

- Seal strength, leak, and integrity testing

- 0-300 mm

- 1-5 kg

- 900 mm

- 1-3

- 32 kg

- 0-100 N (can be customized)

- 0-0.9 MPa

- <10 ms

- 5C-35C

- Testing seal integrity for pet food bags, pouches, and packaging

- 0.5% FS

- 0-900 mm

- AC 220V, 50Hz

Product Description

Product FeaturesNote1

Multiple Test Modes & Automatic Testing Process

- Positive pressure method

- Multiple test modes including burst test, creep test, creep-to-failure test and pressure retaining test

- Dual test methods of restraint distension and unrestraint distension at customer's choice

- Real-time display of test curves and automatic statistics of test data

- Test range can be selected for non-standard tests

- Main components and parts are supplied by well-known global manufacturers, with guaranteed performance

Innovative Real-time Monitoring of Gas Inlet Flow

- Real-time monitoring of gas inlet flow under high pressure ensures the uniform testing condition during testing process

- High repeatability of test data

Brand New Patented Intelligent Touch Operating System

- Industrial grade touch screen, one-button operation, simplified operating interface, remote upgrade and maintenance

- Chinese and English operating interface

- Automatic data storage and power failure memory to prevent data loss

- Storage up to 1200 test records

- Multiple-level user management and login with password

- Micro-printer and USB ports for data transmission (optional)

- The instrument conforms to the requirements of GMP (optional)

- Labthinks unique DataShiledTM System for data management and connecting with information system (optional)

Test StandardNote1

ISO 11607-1, ISO 11607-2, GB/T 10440, GB 18454, GB 19741, GB 17447, ASTM F1140, ASTM F2054, GB/T 17876, GB/T 10004, BB/T 0025, QB/T 1871, YBB 00252005, YBB 00162002

| Basic Applications |

|---|

|

|

|

|

| Extended Applications |

|

|

|

|

|

Technical SpecificationsNote2

| Specifications | C660M Leak and Seal Strength Tester |

|---|---|

| Test Range | 0 600 KPa; 0 87.0 psi (standard) |

| 0 1.6 MPa; 0 232.1 psi (optional) | |

| Resolution | 0.1 KPa / 0.01 psi |

| Pressure Accuracy | 0.25%FS |

| Gas Injection Head | I10 mm (standard) I4 mm, I1.6 mm (optional) |

| Gas Flow Rate | 0.0110L/min |

| Pressure Retaining Time | 0.1s 999999.9 s |

| Gas Supply | Air |

| Gas Supply Pressure | 0.6MPa 0.7MPa (87psi 101psi) |

| Port Size | I8 mm PU Tubing |

| Instrument Dimension | 334 mm (L) x 230 mm (W) x 200 mm (H) |

| Test Frame Size | 305 mm (L) x 356 mm (W) x 338 mm(H) |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Net Weight | 8Kg (Instrument) 16Kg (Pedestal) |

Configurations

- Standard Configurations

- Instrument, Test Frame, Sealing Gasket, 8mm PU Tubing (2m)

- Optional Parts

- Micro-printer, Professional Software, Communication Cable, Test Fixtures for Extended Applications, Air Compressor, GMP System, DataShieldTM Note3

- Note

- 1. The gas supply port of the instrument is 8 mm PU Tubing;

2. Customers need to prepare gas supply.

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

Advanced Seal Integrity Testing

Benefit from sophisticated seal integrity assessment for pet food bags, pouches, and trays with pressure decay and bubble emission test methods. The tester allows highly accurate detection of micro-leaks, ensuring product freshness and regulatory compliance. It supports both manual and automatic programmable cycles, suitable for routine quality checks and thorough inspections.

User-Friendly Digital Operation

Enjoy an intuitive microcomputer-controlled system, complete with a digital LCD touchscreen, for seamless operation. The equipment enables easy test parameter setup, real-time monitoring, and straightforward selection between tests. With direct data transfer via USB or RS232 ports and memory storage for up to 500 results, recordkeeping and traceability are fully optimized.

Comprehensive Compliance and Customization

Adhering to leading international standards such as ASTM F2096, ASTM F88, and ISO 11607-1, this tester is engineered for versatility, accommodating up to 300 mm wide and 900 mm tall samples with capacity ranging from 1-5 kg. A customizable interface and language support enable adaptation to varied production needs, supporting global export operations effectively.

FAQ's of Testing Pet Food Bags seal integrity for Freshness and Safety:

Q: How does the Seal Integrity Tester assess the freshness and safety of pet food bags?

A: The tester utilizes pressure decay and bubble emission methods, applying clean compressed air to the packaging. By monitoring pressure changes and observing for bubble emissions, it detects leaks or compromised seals, ensuring that each bag maintains the required freshness and product integrity.Q: What types of packaging can be tested with this equipment?

A: This machine supports flexible pouches, bags, and trays, accommodating specimens up to 300 mm in width and 900 mm in height, with a capacity of 1-5 kg. It is suitable for various packaging formats commonly used in the pet food industry.Q: When should seal integrity testing be performed during the packaging process?

A: Testing is recommended at critical control points such as after filling and sealing operations or during routine quality assurance checks. Implementing regular seal integrity tests helps identify issues before products reach consumers, ensuring consistent freshness and safety standards.Q: Where can the data from seal testing be accessed or stored?

A: Test data can be viewed in real-time on the LCD touchscreen, downloaded externally via USB or RS232 communication interfaces, and is automatically stored in the equipment's memory, which holds up to 500 test results for comprehensive traceability.Q: What is the process for conducting seal integrity tests with this machine?

A: Operators place up to three specimens in the chamber, select the desired test program (manual or automatic), and start the process using the touchscreen controls. The system applies pressure, monitors seal performance, and provides immediate audio-visual alerts and digital results upon completion.Q: How does the tester comply with relevant international standards?

A: The equipment is built to conform with ASTM F2096 for bubble emission testing, ASTM F88 for seal strength, and ISO 11607-1 for packaging of terminally sterilized medical devices, ensuring it meets strict global safety and quality requirements for packaging integrity.Q: What are the main benefits of using this Seal Integrity Tester?

A: Key benefits include enhanced leak detection accuracy, automated and digital workflows that boost testing efficiency, comprehensive data management, customizable language settings, compliance with major standards, and reliable audio-visual alarms-all contributing to superior product quality assurance in pet food packaging.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Package Leak Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese