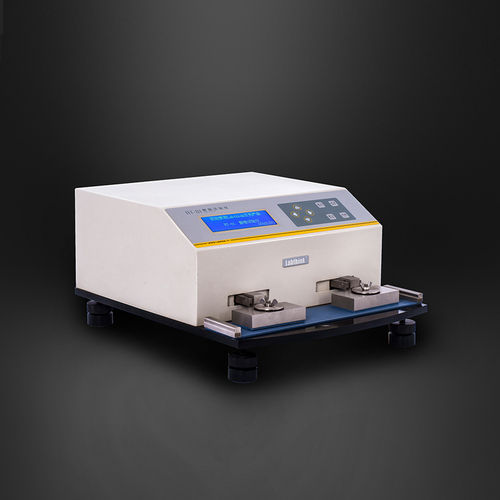

Sutherland Rub Method ink abrasion tester

50000 USD ($)/Set

Product Details:

- Humidity 40%80% RH

- Power Supply AC 220V, 50Hz

- Max Height 350 mm

- Features Adjustable rub cycles, different speed selection

- Hardness Standard

- Accuracy 1 cycle

- Response Time Instant

- Click to View more

X

Sutherland Rub Method ink abrasion tester Price And Quantity

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

Sutherland Rub Method ink abrasion tester Product Specifications

- Digital Counter

- Push button

- Rubbing abrasion resistance ink test

- 2.5 inches (approx. 64 mm)

- 10C40C

- 60 x 152 mm (approx.)

- 09999 cycles

- 1 cycle

- 38 kg

- Semi-automatic

- Instant

- 1 cycle

- 152 mm

- Standard

- Adjustable rub cycles, different speed selection

- 21, 42, 85, 127 cycles/min

- AC 220V, 50Hz

- 350 mm

- 40%80% RH

- 50 Hz

- Ink Abrasion Tester

- Up to 9999 rubs

- Bench-top

- Single test

- Print rub and abrasion resistance testing

- Standard

- 220V AC

- 1 per test

- Digital / Manual

Product Description

Features of Ink Rub Tester

- 4 test modes of dry rub, wet rub, wet transfer, and wet smear and 4 different test speeds to meet different test requirements

- Dual stations with arc movement structure can test equivalent or distinct specimens simultaneously

- Intelligent design of power failure memory and buzzer reminding ensure the safety of test operation

- The instrument is controlled by micro-computer, with PVC operation panel, LCD and menu interface, which is convenient for users to operate or view the test data

Testing Standards

This test instrument conforms to the standard: ASTM D5264, TAPPI T830

Testing Applications

RT-01 Ink Rub Tester is applicable to the determination of abrasion resistance of:

| Basic Applications |

|---|

|

|

Technical Specifications

| Specifications | RT-01 Ink Rub Tester |

|---|---|

| Rub Pressure | 8.9 N(2lb); 17.8N(4lb) |

| Rub Speed | 21, 42, 85, 106 cpm |

| Rub Mode | Arc Reciprocating Movement |

| Rub Times | 0 999999 |

| Number of Specimens | 1 2 |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Instrument Dimension | 485 mm (L) x 390 mm (W) x 230 mm (H) |

| Net Weight | 40 kg |

Configurations

- Standard Configurations

- Instrument, 8.9N (2lb) Test Block, 17.8N (4lb) Test Block and Rubber Cushion

- Optional Parts

- Customized Test Block

Precision Abrasion Testing for Print Quality Assurance

This abrasion tester is designed to deliver accurate and consistent evaluations of ink rub resistance. Its digital counter and adjustable settings enable users to tailor test parameters, ensuring precise compliance with ASTM D5264 standards. The inclusion of a high-grade rubber roller and digital/manual control enhances flexibility and adaptability, making it ideal for manufacturers, exporters, and suppliers prioritizing print quality and durability.

User-Friendly Operation with Enhanced Safety

With its programmable digital timer and user-centric push-button interface, the device simplifies the testing workflow. Key safety features, such as overload protection and an emergency stop, safeguard both operators and samples. Factory calibration ensures accurate readings right out of the box, eliminating the need for immediate recalibration. The powder-coated steel body offers durability and reduces maintenance requirements.

FAQ's of Sutherland Rub Method ink abrasion tester:

Q: How do I operate the Sutherland Rub Method Ink Abrasion Tester?

A: To operate, securely clamp the sample using the clamp-type holder, set the desired speed and number of cycles on the digital counter, adjust weights if necessary, and start the test using the push-button interface. The programmable timer controls test duration, and the digital display provides a real-time cycle count.Q: What type of samples can this ink abrasion tester accommodate?

A: The tester is designed for single specimens up to 60 x 152 mm (approx.), making it suitable for testing most printed substrates like paper, cardboard, labels, or packaging in accordance with standard rub resistance requirements.Q: When should I use the emergency stop or overload protection features?

A: Engage the emergency stop or rely on the built-in overload protection if you notice abnormal operation, unexpected machine behavior, or suspect sample jamming. These safety mechanisms are in place to protect both the operator and the equipment during testing.Q: Where is this tester commonly used and who are the primary users?

A: This abrasion tester is commonly implemented in print manufacturing, packaging quality control labs, and by exporters seeking compliance with ASTM D5264. Primary users include quality assurance engineers, laboratory technicians, manufacturers, and suppliers focused on ink performance.Q: What benefits does the programmable timer and adjustable speed provide?

A: The programmable digital timer and multiple speed settings (21, 42, 85, 127 cycles/min) allow for custom test parameters, simulating real-world rub conditions and ensuring repeatability. This enhances test relevance for diverse printed materials and durability requirements.Q: How do I maintain optimal calibration and ensure measurement accuracy?

A: The tester comes factory calibrated for immediate use. To maintain accuracy, perform periodic operational checks as advised in the instruction manual, keep the roller and sample holder clean, and avoid excessive vibration or shock to the device.Q: Can I conduct tests at varying environmental conditions?

A: Yes, the tester is designed to perform reliably within humidity levels of 40%-80% RH and temperatures of 10C-40C, covering a wide range of typical lab environments for dependable, standardized results.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Ink Rub Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese