Flow Wrap Seal Integrity Testing for Product Safety and Quality

50000 USD ($)/Set

Product Details:

- Resolution 0.01 bar

- Display Type Digital

- Operating Voltage 230V AC

- Accuracy 0.5% F.S.

- Number of Specimens 1 per cycle

- Specimen Size Up to 300 mm width

- Port Size 1/4 BSP

- Click to View more

X

Flow Wrap Seal Integrity Testing for Product Safety and Quality Price And Quantity

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

Flow Wrap Seal Integrity Testing for Product Safety and Quality Product Specifications

- 300 mm max

- Digital

- 45 kg

- 0.01 bar

- Varies by model

- Flow wrap seal strength and integrity testing

- 1 per cycle

- 0.5% F.S.

- 230V AC

- 1/4 BSP

- Up to 300 mm width

- Up to 200 mm

- 10-30 tests/hr (adjustable)

- 10~40C

- RS232, USB

- Automatic

- 0.5 - 5 bar

- Automatic test cycle, data logging, user-friendly interface

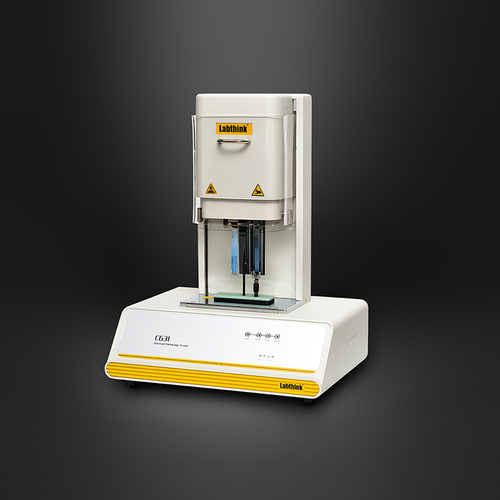

- Flow Wrap Seal Integrity Tester

- 2 seconds

- 230V AC, 50 Hz

- 0.5 - 0.7 MPa

- 350 mm

- 85% RH (non-condensing)

- Detection of leaks and weak points in flow wrap packaging

- 0 to 5 bar

- 50 Hz

- Digital Touch Panel

- Table Top

Product Description

Product FeaturesNote1

- Ten (upper and lower) sealing jaws with metal surfaces to obtain heat sealing parameters that are close to actual parameters

- Digital P.I.D. temperature control technology ensures the preset temperature to be reached rapidly without fluctuations

- Auto constant pressure technology guarantees the stable sealing pressure, requiring no manual adjustment

- Auto leveling technology of sealing jaws ensures uniform sealing performance

- Wide range control of temperature, pressure and time that meet various test conditions

- Manual or pedal switch, as well as anti-scald design provides convenient and safe operating environment

- Professional software supports remote operation for convenient data saving, exporting and printing

Excellent User-oriented, High-efficient and Safe Designs

- The instrument can complete 5 groups of specimen tests at a time, helps the user to obtain heat sealing parameters of the specimens accurately and efficiently.

- The temperature of upper sealing jaws and lower sealing jaws can be controlled separately, which can meet the requirements for different combination of temperatures

- Separated type sealing jaws can be easily replaced

- Manual and pedal switch mode for starting test as well as the anti-scald design ensures the safe operation

High-end and Easy-to-Use Embedded Computer-controlled System

- The instrument is equipped with large size tablet (touch screen), which is easy to operate and observe during the test process

- Brand new software simplifies the testing process.

- The system supports comparison analysis of groups of test data with unit conversion function

- USB ports and internet interface for connecting of external device and data transmission

- The instrument conforms to the requirements of GMP (optional)

- Labthinks unique data security system separates the test data from the computer to avoid the risks caused by computer virus

- Labthinks unique DataShiledTM System for data management and connecting with information system (optional)

Test StandardNote1

ASTM F2029, QB/T 2358, YBB 00122003

Applications

| Basic Applications |

|---|

|

|

| Extended Applications |

|

Technical SpecificationsNote2

| Specifications | C630H Heat Seal Tester |

|---|---|

| Sealing Temperature | Room temperature 300C |

| Sealing Pressure | 0.1Mpa 0.7 Mpa (14psi 101psi) |

| Resolution of Pressure | 0.001 MPa |

| Dwell Time | 0.1 999.99 s |

| Resolution of Time | 0.01 s |

| Resolution of Temperature | 0.1C |

| Temperature Fluctuation | 0.2C |

| Temperature Accuracy | 0.5C (single point calibration) |

| Temperature Gradient | 20C |

| Gas Supply Pressure | 0.7 Mpa (101psi) |

| Port Size | 8 mm PU Tubing |

| Sealing Area | 40 mm 10 mm |

| Number of Sealing Jaws | 5 groups of upper and lower sealing jaws with independent temperature control |

| Instrument Dimension | 375mm (L) 360 mm (W) 518mm (H) |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Net Weight | 55 kg |

Configurations

- Standard Configurations

- Instrument, Tablet, Pedal Switch, High-temperature Welding Cloth, Sample Cutter, 8mm PU Tubing (2m)

- Optional Parts

- High-temperature Welding Cloth, Air Compressor, GMP System, DataShieldTM Note3

- Note

- 1. The gas supply port of the instrument is 8 mm PU Tubing;

2. Customers need to prepare gas supply.

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

Efficient Seal Compatibility

This tester adapts easily to various seal types, including fin, lap, and custom flow wrap seals, providing flexibility across a range of packaging formats. It allows for comprehensive testing of different materials and configurations, making it a valuable asset for industries requiring high-quality seal verification and product integrity assurance.

Comprehensive Safety Features

With safety as a priority, the Flow Wrap Seal Integrity Tester includes emergency stop and overload protection. These features ensure operator well-being throughout testing. The robust design, coupled with automatic control, reduces risks while maximizing operational uptime and reliability in any industrial setting.

Advanced Digital Reporting & Calibration

Users benefit from digital and graphical reporting, delivering precise, easily interpretable results. The built-in calibration routine simplifies maintenance, ensures ongoing accuracy, and supports compliance with global testing standards. Automated data logging fosters traceability and streamlines quality assurance processes.

FAQs of Flow Wrap Seal Integrity Testing for Product Safety and Quality:

Q: How does the Flow Wrap Seal Integrity Tester operate to detect leaks and weak points?

A: The tester uses burst, creep, and peel modes to apply controlled pressure cycles to flow wrap seals, monitoring for any drop or anomaly in pressure. This process reveals leaks or weak points with high accuracy, allowing for targeted quality assurance and compliance with industry standards.Q: What types of seals and package sizes can be tested with this equipment?

A: The device accommodates fin, lap, and custom flow wrap seals, supporting specimens up to 300 mm in width and 350 mm in height. Its adaptable design allows manufacturers to run tests on a variety of packaging formats without the need for multiple machines.Q: When should companies use this tester during their production process?

A: Seal integrity testing is recommended during routine quality checks, production changeovers, or whenever new packaging materials are introduced. Regular testing ensures product safety, prevents leaks, and maintains compliance with ASTM F88 and ISO 11607-1.Q: Where is this Flow Wrap Seal Integrity Tester typically installed and used?

A: This table-top unit is suited for packaging lines, quality assurance labs, or R&D environments. Its compact size and straightforward digital touch panel make it practical for dealer, exporter, supplier, or manufacturer facilities, particularly those with space constraints.Q: What is the process for calibrating and reporting test data?

A: Calibration is achieved through the built-in routine accessible from the digital interface, ensuring accuracy for every test. Test results are provided in both digital and graphical formats, with reporting and data logging handled automatically for robust traceability.Q: What are the main benefits of using this automated integrity tester?

A: Automated operation increases throughput and consistency, while comprehensive safety features protect operators. The devices precise measurement and digital reporting enhance quality control, reduce manual errors, and support regulatory compliance, providing significant value for all stakeholders.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Heat Seal and Hot Tack Testers' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese