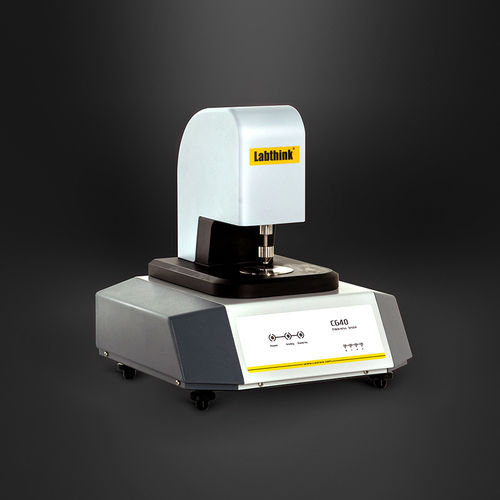

Tearing performance Tester to Guarantee High-Quality Cosmetic Packaging

Product Details:

- Automation Grade Semi-Automatic

- Temperature 15C 40C

- Features High Precision, Easy Calibration, User Friendly Interface

- Response Time Instantaneous

- Operating Voltage 220 V AC

- Display Type Digital LCD

- Frequency 50 Hz

- Click to View more

Tearing performance Tester to Guarantee High-Quality Cosmetic Packaging Price And Quantity

- 50000.00 - 100000.00 USD ($)/Set

- 1 Set

- 50000 USD ($)/Set

Tearing performance Tester to Guarantee High-Quality Cosmetic Packaging Product Specifications

- Tearing Performance Tester

- 50 Hz

- Digital LCD

- Adjustable

- 220 V AC

- Microprocessor Based

- Instantaneous

- RS232/USB

- 1/4 inch

- 1 mN

- Laboratory/Quality Control

- 0.6 MPa

- 1% of reading

- 200 mm/min

- Semi-Automatic

- High Precision, Easy Calibration, User Friendly Interface

- 15C 40C

- Approx. 23 kg

- Bench-top

- 35% 85% RH

- 10 32,000 mN

- 10 32,000 mN

- 1 (per test)

- AC 220V, 50Hz

- Cosmetic packaging material tear resistance measurement

- 63 x 50 mm or as per standard

- 15 mm

- 210 mm

- 100 mm

Product Description

Product Features Notes1

- Computer control, automatic electronic measurement, easy to operate.

- Pneumatic sample clamping and automatic pendulum release can effectively avoid the systematic error caused by human factors.

- Computer assisted adjustment system can ensure the instrument is always in the best test state.

- It can be equipped with multiple groups of pendulum capacity to meet different test requirements.

- Professional software supports the data output of various test units.

- Standard RS232 interface is convenient for external access and data transmission of the system.

Test Principle

Lift the pendulum to a certain height to make it have a certain potential energy; when the pendulum swings freely, it uses its own stored energy to tear the sample; the computer control system calculates the energy consumed in tearing the sample, so as to obtain the force required for tearing the sample.

Reference Standard Notes1

ISO 6383-1-1983, ISO 6383-2-1983, ISO 1974, GB/T 16578.2-2009, GB/T 455, ASTM D1922, ASTM D1424, ASTM D689, TAPPI T414

Test Applications

| Basic Applications |

|---|

|

|

|

| Extended Applications |

|

|

|

|

Technical Parameters Notes2

| Items | Parameters |

|---|---|

| Pendulum Capacity | 200gfa400gfa800gfa1600gfa3200gfa6400gf |

| Air Source Pressure | 0.6 MPa (supplied by user) |

| Air Connection | I 4 mm polyurethane pipe |

| Dimensions | 480 mm (L) 380 mm (W) 560 mm (H) |

| Mainframe Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Net Weight of Mainframe | 40kg (200gf basic pendulum) |

Product Configuration Notes1

| Standard configuration | Mainframe, 1 Basic pendulum, 1 calibration weight, professional software, communication cable |

|---|---|

| Options Notes3 | Basic pendulum: 200gf, 1600gf Weight gain: 400gf, 800gf, 3200gf, 6400gf Calibration weights: 200gf, 400gf, 800gf, 1600gf, 3200gf, 6400gf computer |

| Notes | The air source interface of the machine is I 4 mm polyurethane pipe; the air source is provided by the user |

Note 1: The product functions, reference standards and configuration information are subject to the specific marks in the "technical indicators".

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory according to the requirements and conditions of relevant laboratory environmental standards.

Note 3: "basic pendulum" should select at least one pendulum capacity, "correction weight" should be consistent with the pendulum capacity, and it should be noted when placing an order.

Precision Testing for High-Quality Packaging

The Tearing Performance Tester is engineered to guarantee consistent quality in cosmetic packaging. It provides high-precision tear resistance measurements, allowing manufacturers to evaluate material durability before production. With adjustable capacities, instant data response, and a digitally controlled system, users can ensure that their packaging meets industry standards every time.

User-Friendly and Versatile Operation

Managing the Tearing Performance Tester is made simple with its digital LCD display, intuitive interface, and easy calibration process. The equipment supports both English and Chinese languages, accommodating various users. Its pneumatic clamping and adjustable test parameters offer versatility for testing different materials and conforming to industry or custom standards.

FAQ's of Tearing performance Tester to Guarantee High-Quality Cosmetic Packaging:

Q: How does the Tearing Performance Tester ensure reliable tear resistance results for cosmetic packaging?

A: The tester utilizes precision sensors, adjustable tear angles (90 or 135), and a microprocessor-based control mode to deliver consistent and accurate measurements within 1% of reading. Its digital LCD display provides instant results, while calibration can be set manually or automatically for optimal reliability.Q: What materials can be tested using this equipment, and what are the specimen requirements?

A: This tester is compatible with a wide range of packaging materials, including paper, film, foil, and laminates. The standard specimen size is 63 x 50 mm, but it may be adjusted to meet specific standards or requirements.Q: When should calibration be performed on the Tearing Performance Tester?

A: It's recommended to calibrate the instrument before initiating a test series, after any major maintenance, and periodically according to your quality assurance protocols. Both manual and automatic calibration options are available for user convenience.Q: Where should the Tearing Performance Tester be installed for optimal performance?

A: The equipment should be set up in a clean, dust-free, and vibration-free laboratory area. Ensure that the indoor temperature ranges between 15C - 40C and humidity remains between 35% - 85% RH to maintain accurate results.Q: What is the process for conducting a tear resistance test using this tester?

A: Place the specimen into the pneumatic sample clamping system, select the desired tear angle, and set test parameters via the digital interface. Once started, the machine initiates tearing at 200 mm/min, automatically records results, and displays data instantly.Q: How can the stored test data be accessed and exported from the equipment?

A: The tester can store up to 1000 test results in its memory. Data can be accessed, reviewed on the display, or exported to external devices using the available RS232 or USB interfaces for further analysis or record-keeping.Q: What are the primary benefits of using this tester for cosmetic packaging quality assurance?

A: Users benefit from high-precision, repeatable measurements, user-friendly operation, extensive data storage, and robust safety features. The device ensures cosmetic packaging is thoroughly tested for durability, helping manufacturers meet international quality standards and reduce material failure risks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese