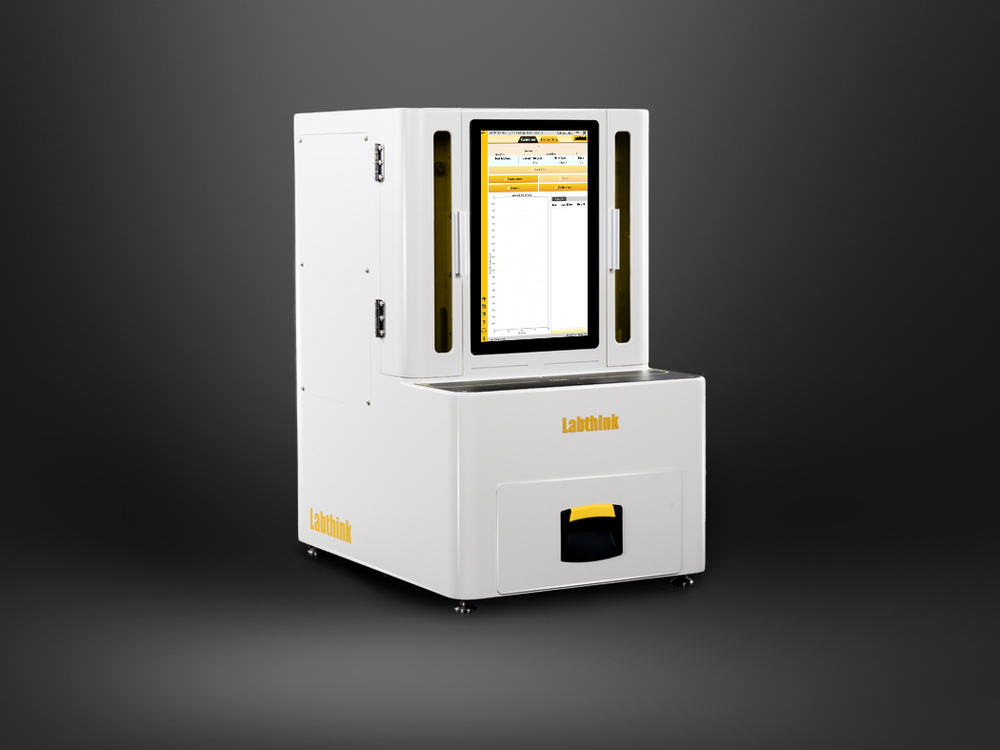

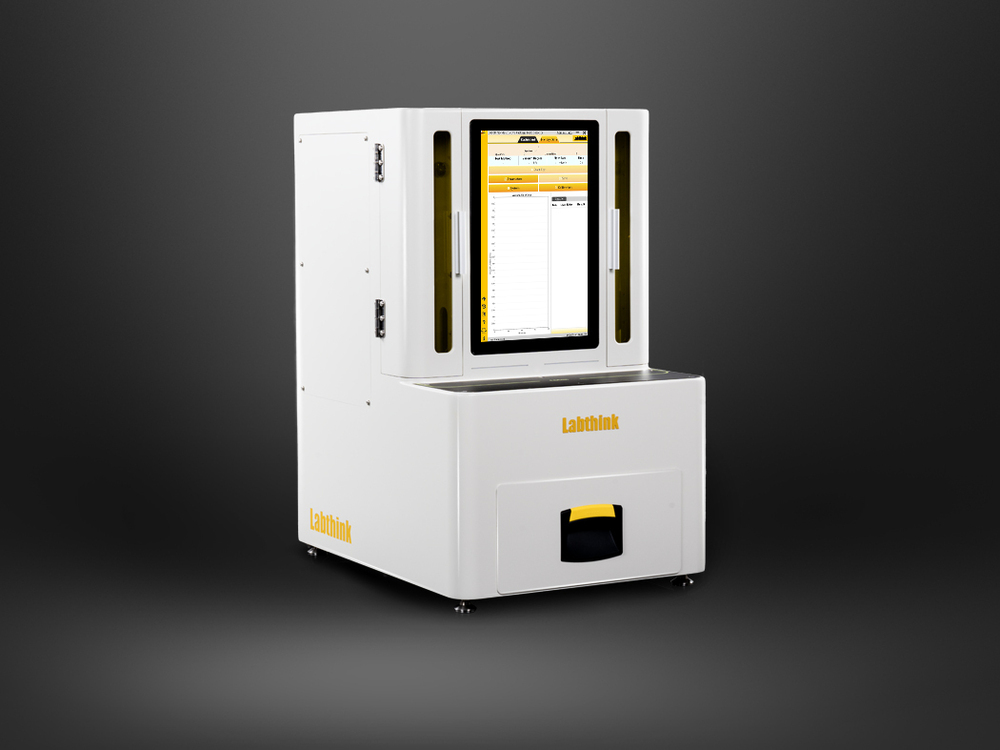

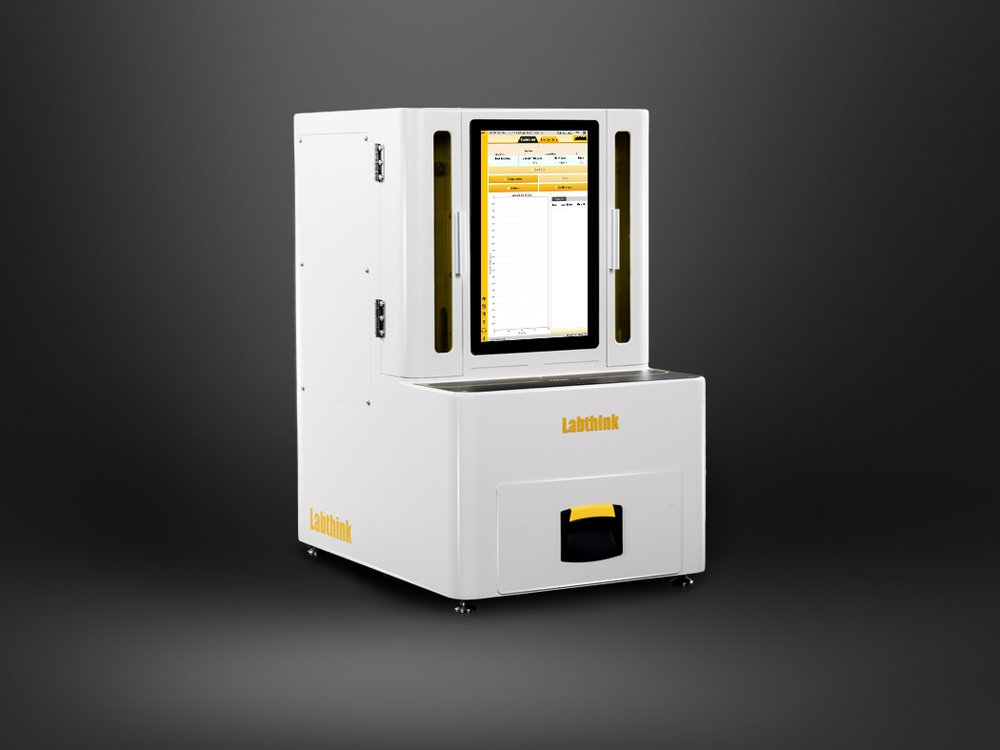

Vacuum Decay Approach Non-Destructive Leak Testing Instrument

50000 USD ($)/Set

Product Details:

- Display Type LCD digital display

- Resolution 0.01 mbar

- Max Height 400 mm chamber

- Gas Pressure 0.5 0.8 MPa

- Number of Specimens 1 at a time

- Features Non-destructive, automatic leak measurement, data storage

- Humidity 85% RH

- Click to View more

X

Vacuum Decay Approach Non-Destructive Leak Testing Instrument Price And Quantity

- 50000 USD ($)/Set

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

Vacuum Decay Approach Non-Destructive Leak Testing Instrument Product Specifications

- 85% RH

- 230V AC, 50 Hz

- 0-100 mm adjustable

- Customizable (standard: up to 300 mm length)

- 10C 40C

- 50 Hz

- 400 mm chamber

- LCD digital display

- 0.01 mbar

- 0.5 0.8 MPa

- 1 at a time

- Non-destructive, automatic leak measurement, data storage

- 45 kg

- < 2 sec

- Microprocessor-based digital control

- Benchtop

- Laboratory / Quality Control

- 230V AC

- Single chamber

- 150 mm

- Semi-Automatic

- G1/4

- 0.1 600 mbar

- Vacuum Decay-based Leak Tester

- RS232 / USB

- 2% F.S.

- 0.1 600 mbar

- Up to 10 tests/min

- Non-destructive package and seal integrity testing

Product Description

Technical Parameters

Table 1: Test Parameters Note2

| ParameterModel | C690H | |

|---|---|---|

| Testing Range | um(Reference aperture size USP1207) | 3i8igreat leakage |

| Detection Lower Limit | um | 3 |

| Resolution | um | 0.1 |

| Repeatability | um | 1 |

| Pressure Range | kPa | -100i0ii14100 |

| Extended Functions | 21 CFR Part11 | Optional |

| GMP computer system requirements | Optional | |

Table 2: Technical Specifications

| Testing Cell | 1 set for A group and 1 set for B group |

| Sample Feeder | 1 set for A group and 1 set for B group |

| Sample Size | I45 mm80mmNote3 |

| Sample Quantity | 20120 pieces |

| Gas Specifications | Compressed Air (Gas source is provided by the user) |

| Gas Source Pressure | 40.6 PSI / 500 kPa |

| Port Size | I6 mm Polyurethane tube |

| Dimensions | 33.4 H x 19.6 W x 28.7 D (85cm 50cm 73cm) |

| Power | 120VAC10% 60Hz / 220VAC10% 50Hzi14select one from the twoi14 |

| Net weight | 209Lbs (95kg) |

Product Configuration

| Standard Configuration | Mainframe, embedded tablet computer, software, flow meter, European vacuum pump, I6 mm polyurethane tube |

|---|---|

| Customization | Test cell and sample feeder of group A, test cell and sample feeder of group B, negative standard reference sample and positive standard reference sample designed according to sample specifications |

| Optional Parts | GMP computer system requirements, 21 CFR Part11, air compressor, IQ/OQ/PQ documents |

Note 1: The described product characteristics are subject to the specific annotation of the "Technical Parameters" table.

Note 2: The parameters in the table are measured in the Labthink laboratory by professional operators according to the requirements and conditions of the relevant laboratory environmental standards.

Note 3: Group C test cell can be customized for samples beyond the "Sample Size", but the lower detection limit and test range will change according to the sample size, and the actual delivery shall prevail.

Premium Non-Destructive Leak Testing

Utilizing vacuum decay methodology, this leak tester provides reliable, repeatable results without damaging the tested item. It meets stringent regulatory standards and is suitable for pharmaceutical, food, and medical packaging integrity assessment. Fast test cycles and a user-friendly interface allow for efficient quality control.

Advanced Digital Control and Data Management

Equipped with a digital LCD display and microprocessor-based controls, the instrument allows precise adjustment of test parameters. Result archiving and trend analysis functionalities streamline documentation, while export options via USB or RS232 interface facilitate seamless data transfer and reporting.

Robust Design and Flexible Compatibility

Manufactured from stainless steel (SS304), the vacuum chamber accommodates a wide array of packaging types and sizes. With customizable specimen sizing and adjustable testing chamber, the unit is suitable for both standard and unique applications, ensuring reliability in diverse laboratory setups.

FAQ's of Vacuum Decay Approach Non-Destructive Leak Testing Instrument:

Q: How does the vacuum decay leak testing process work with this instrument?

A: The vacuum decay leak testing process involves placing a sealed package into the stainless steel chamber, where an automatic programmable vacuum is applied. The device monitors pressure changes within the chamber; any increase indicates a potential leak, allowing for precise, non-destructive detection.Q: What standard compliance does this vacuum leak tester meet?

A: This instrument fully complies with ASTM F2338 and ISO 11607-1, ensuring its suitability for regulated environments, including pharmaceutical, medical, and food packaging quality control.Q: When and where can this equipment be effectively used?

A: The tester is optimized for laboratory and quality control settings, and is ideal for use during routine package integrity checks, product development, or before product release, ensuring consistent package and seal integrity.Q: What types and sizes of packages can be tested with this machine?

A: It accommodates blister packs, bottles, pouches, vials, and trays. The chamber supports custom specimen sizes up to 300 mm in length (standard) and 400 mm in height, making it adaptable to various packaging formats.Q: How is data handled and exported from the device?

A: All test results are digitally archived in the system. Users can export or print reports via USB or RS232 interfaces, and benefit from trend analysis tools built into the software for comprehensive quality tracking.Q: What are the key benefits of using this vacuum decay leak tester?

A: Key advantages include non-destructive leak detection, high accuracy (2% F.S.), rapid test speed (up to 10 tests/min), automatic vacuum control, customizable settings, and robust stainless steel construction for dependable, long-lasting performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Package Leak Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese