Leather Breathability Testing Ensuring Comfort and Hygiene in Clothing

Product Details:

- Response Time 1 s

- Test Range 0.1-1000 g/m/24h

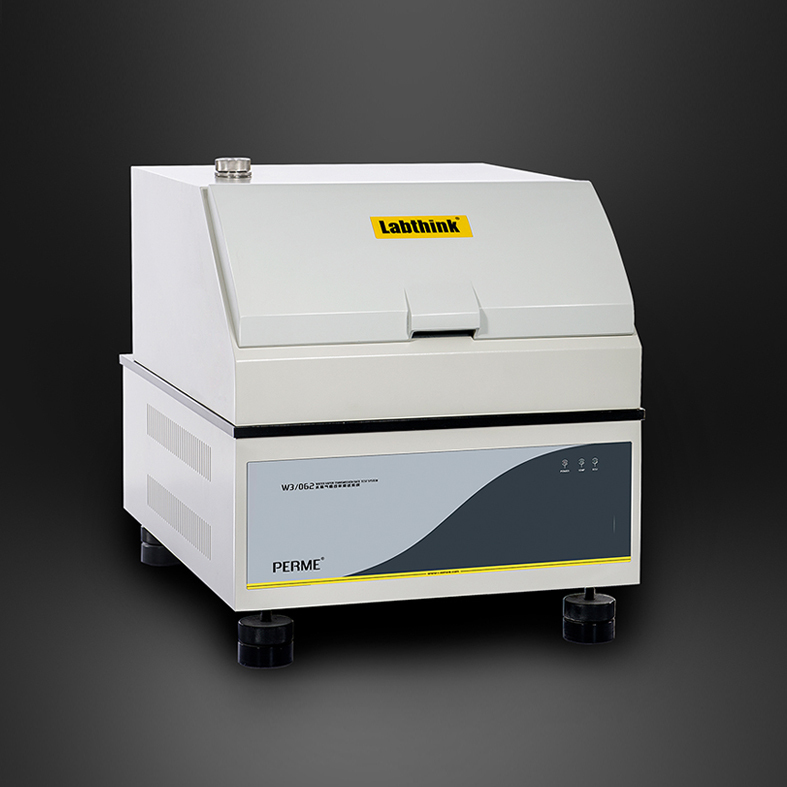

- Equipment Type Leather Breathability Tester

- Measuring Range 0.1-1000 g/m/24h

- Interface Type USB, RS232

- Number of Specimens 4

- Accuracy 1% of reading

- Click to View more

Leather Breathability Testing Ensuring Comfort and Hygiene in Clothing Price And Quantity

- 50000 USD ($)/Set

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

Leather Breathability Testing Ensuring Comfort and Hygiene in Clothing Product Specifications

- Semi-Automatic

- 220V AC, 50Hz

- 100 x 100 mm

- 8 mm

- 15-50C

- Auto calibration, Data logging, Touch screen

- Microprocessor Control

- 50 Hz

- Leather clothing, garments, upholstery

- Testing breathability of leather materials

- 220 V

- 0.01 g/m/24h

- 25 mm

- 25 kg

- 0.5-5 bar

- Digital LCD

- 10 mm/min

- Benchtop

- 4 Samples

- 40-95% RH

- 100 mm

- 1 s

- 0.1-1000 g/m/24h

- Leather Breathability Tester

- 4

- 1% of reading

- 420 mm

- 0.1-1000 g/m/24h

- USB, RS232

Product Description

Principle

Under a certain test temperature, a constant humidity difference is generated between two sides of the test specimen. The water vapor permeates through the specimen and into the dry side. By measuring the weight changes of the test dish in different time, water vapor transmission rate and other parameters can be obtained.

Standards

This test instrument conforms to the following standards:

ISO 2528, GB 1037, GB/T 16928, ASTM E96, ASTM D1653, TAPPI T464, DIN 53122-1, JIS Z0208, YBB 00092003

Applications

This instrument is applicable to the determination of water vapor transmission rate of:

| Basic Applications |

|---|

|

|

|

|

| Extended Applications |

|

|

|

|

|

|

|

Technical Specifications

| Specifications | Film Test |

|---|---|

| Test Range | 0.110,000 g/m224h (Water Method) 0.12,500 g/m224h (Desiccant Method) |

| Number of Specimens | 16 with independent test results |

| Accuracy | 0.01 g/m224h |

| Resolution | 0.001 g (Customization Available) |

| Temperature Range | 15C55C (standard) |

| Temperature Accuracy | 0.1C(standard) |

| Humidity Range | Water Method: 90%RH 70%RH Note1 |

| Desiccant Method: 10%RH98%RH Note2 | |

| Humidity Accuracy | 1%RH |

| Air Velocity | 0.52.5 m/s (customization available) |

| Specimen Thickness | 3 mm (customization is available for other thickness) |

| Test Area | 33 cm2 |

| Specimen Size | I74 mm |

| Test Chamber Size | 45 L |

| Gas Supply | Air |

| Gas Supply Pressure | 0.6 MPa |

| Port Size | I6 mm PU tubing |

| Instrument Dimension | 660 mm (L) x 580 mm (W) x 580 mm (H) |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Net Weight | 80 kg |

Note1: Herein the "Humidity means the humidity difference between the two sides of the film specimen. The humidity in the test chamber is 10%30%RH accordingly.

Note2: Herein the "Humidity means the humidity difference between the two sides of the film specimen. The humidity in the test chamber is 10%RH-98%RH when the temperature is 15 to 40 C, 10%RH-90%RH when the temperature is 45 C, 10%RH-80%RH when the temperature is 50 C, 10%RH-70%RH when the temperature is 55 C.

Configurations

- Standard Configurations

- Instrument, Professional Software, Test Dishes, Desiccant Tube, Humidity Generator, Calibration Weight, Communication Cable, Round Sample Cutter and Valve Set

- Optional Parts

- Satellite Base, Reference Film, Air compressor and Desiccant

Ensuring Reliable Leather Comfort Testing

The Leather Breathability Tester employs dynamic airflow measurement technology, offering meticulous analysis of material breathability to ensure maximum comfort and hygiene. Its stainless steel clamp securely holds up to four specimens, delivering accurate and repeatable results for textile engineers and quality control teams involved in clothing and upholstery manufacturing. The digital LCD interface and auto-calibration functions streamline testing and data handling, making the device both user-friendly and highly dependable in professional laboratory settings.

Advanced Features and Safety Standards

Built with safety and performance in mind, the tester integrates overload protection, an emergency stop, and noise control (<60 dB) for operator confidence. Automatic calibration at six-month intervals and compliance with global standards like ISO 17229 and EN ISO 20344 guarantee reliable and traceable results. The robust export-grade packaging ensures safe delivery and installation worldwide, reinforced by onsite installation and professional training for seamless adoption.

FAQ's of Leather Breathability Testing Ensuring Comfort and Hygiene in Clothing:

Q: How is leather breathability measured using this tester?

A: This tester uses a high-precision digital sensor and dynamic airflow measurement to determine the breathability of leather. Leather samples are clamped securely, and airflow is measured across them, providing accurate readings in units of g/m2/24h via the digital LCD display.Q: What is the typical process for conducting a breathability test on leather?

A: Up to four specimens (each 100 x 100 mm) are mounted in the stainless steel clamps. The microprocessor-controlled test begins with dynamic airflow at a speed of 10 mm/min. Results are captured electronically, with built-in calibration ensuring ongoing accuracy.Q: When and how should the equipment be calibrated?

A: The tester features automatic built-in calibration, with a recommended sensor calibration interval of every six months. This ensures precision and compliance with international testing standards with minimal user intervention.Q: Where is this tester best utilized?

A: Designed for controlled, indoor laboratory environments, the tester is ideal for use by manufacturers, exporters, and suppliers in the leather, garment, and upholstery industries, particularly where professional quality assessments are essential.Q: What are the benefits of using this leather breathability tester?

A: Benefits include highly accurate, repeatable results (1% of reading), large storage capacity (up to 5000 test results), user-friendly touch screen operation, and advanced safety features. Compliance with key ISO and EN standards supports global trade and product certification.Q: Can the data be exported or integrated into other systems?

A: Yes, the tester includes USB and RS232 interfaces for seamless data transfer and integration with external data management systems, facilitating effective record-keeping and further analysis.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'OTR/WVTR Test System' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese