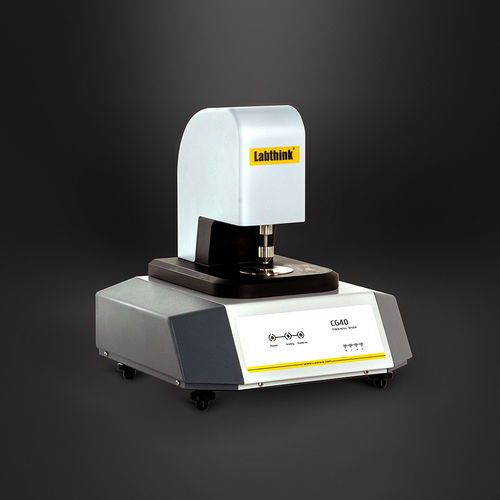

Friction Coefficient Tester for Safety Implications of Friction Control in Industrial Settings

50000 USD ($)/Set

Product Details:

- Hardness Tested specimen hardness 50-90 shore A

- Measuring Range Static and dynamic COF measurement, 0.01-1.50

- Temperature 10-40C

- Resolution 0.001 N

- Gas Pressure 0.6 MPa

- Number of Specimens 1-3

- Max Height 450 mm

- Click to View more

X

Friction Coefficient Tester for Safety Implications of Friction Control in Industrial Settings Price And Quantity

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

Friction Coefficient Tester for Safety Implications of Friction Control in Industrial Settings Product Specifications

- 70 mm

- Testing surface friction and slip resistance for safety compliance

- 6 mm pneumatic input

- AC 220V, 50Hz

- 220 V

- 70 mm x 200 mm

- 0.01 N

- 40-80% RH

- Microprocessor-based digital control

- Evaluation of friction control for safety in industrial environments

- Digital Friction Coefficient Tester

- 50/60 Hz

- USB and RS232

- Digital LCD Display

- 0-30 N

- 10-300 mm/min adjustable

- Tested specimen hardness 50-90 shore A

- 25 kg

- Static and dynamic COF measurement, 0.01-1.50

- 10-40C

- 0.001 N

- 150 mm

- 30 N

- 0.6 MPa

- 1-3

- 450 mm

- High precision sensor, user-friendly software, automatic data logging

- 0.2 s

- Automatic

- Benchtop

Product Description

Features

- Static and kinetic coefficients of friction can be tested for each specimen

- This instrument conforms to multiple standards of ISO, ASTM and GB and the user could select testing methods as required

- Test speed could be preset and adjusted by the users as required

- Sled of specific weight could be customized

- The sliding plane and the sled are treated by degaussing and remanence detection which effectively reduce the system error

- Top quality parts and components made by world famous brands are used to ensure reliable overall product performance

- The instrument is controlled by micro-computer with LCD display, PVC operation panel and menu interface

- Professional operating software support statistical analysis of single specimen, group specimens, superposition analysis of test curves and historical data comparison functions

- Equipped with RS232 port and micro printer port which is convenient to the data transmission and PC connection

- Supports LystemTM Lab Data Sharing System for uniform and systematic data management

Standards

This instrument conforms to various national and international standards:

ISO 8295, ASTM D1894, TAPPI T816, GB 10006

Applications

| Basic Applications |

|---|

|

|

|

|

|

|

| Extended Applications |

|

|

|

|

|

|

|

|

Technical Specifications

| Specifications | MXD-02 Coefficient of Friction Tester |

|---|---|

| Capacity Range | 0 5 N |

| Accuracy | 0.5% FS |

| Stroke | 70 mm, 150 mm |

| Mass of Sled | 200 g (Standard) |

| Sled of specific weight could be customized | |

| Test Speed | 100 mm/min, 150 mm/min |

| Test speed could be adjusted | |

| Environment Condition | Temperature: 232C |

| Humidity: 20%RH 70%RH | |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Instrument Dimension | 630 mm (L) x 360 mm (W) x 230 mm (H) |

| Net Weight | 33 kg |

Configurations

- Standard Configurations

- Instrument, Micro Printer and Sled of 200g

- Optional Parts

- Professional Software, Communication Cable and Customized Sled of 500g

Robust and Accurate Surface Friction Testing

Designed for industrial safety, this friction coefficient tester utilizes high-precision strain gauge technology and automatic electronic calibration to deliver swift, reliable friction measurements. The programmable test temperature, broad test speed range, and versatile settings guarantee adaptability for various surface types and industrial standards.

Comprehensive Data Management and Output

Data collection and reporting are made effortless with large memory capacity, automatic data logging, and support for CSV and PDF exports. The tester interfaces easily via USB or RS232, enabling seamless integration with laboratory or production line data systems for ongoing safety monitoring.

User-Friendly Operation and Enhanced Safety

An ergonomic layout with a quick-release sample clamp, digital LCD, and easy-touch microprocessor controls enhances operational efficiency. Safety is further supported by automatic overload protection, low noise emission, and an IP20 enclosure, ensuring reliable performance without disrupting workplace environments.

FAQ's of Friction Coefficient Tester for Safety Implications of Friction Control in Industrial Settings:

Q: How does this friction coefficient tester enhance safety control in industrial settings?

A: The tester accurately measures the static and dynamic coefficients of friction on various surfaces, helping identify slip risks and enabling facilities to ensure their flooring and materials meet safety standards for accident prevention.Q: What calibration method does the tester use, and how often is calibration needed?

A: It employs an automatic electronic calibration system, ensuring precise results before every test cycle. Manual calibration is not necessary, reducing downtime and user intervention.Q: When is the programmable sample temperature feature most useful?

A: Temperature control (up to 50C) is particularly valuable when simulating real-world industrial environments or processing conditions where temperature can influence surface friction and slip behavior.Q: Where can test data be stored and how can results be accessed?

A: The device stores up to 1,000 results internally. Users can export data conveniently in CSV or PDF format via USB or RS232 for further analysis or archiving.Q: What is the process for setting up a friction test on this machine?

A: Operators place the specimen (up to 70 mm x 200 mm) on the stainless steel test plate, adjust the quick-release clamp, set desired parameters (temperature, speed), and initiate the test via the digital control panel. Results are displayed and stored automatically.Q: How does automatic overload protection benefit users?

A: If the test force exceeds 35 N, the tester immediately shuts off to prevent damage to the equipment or specimen, thus extending machine life and ensuring user safety.Q: What are the main advantages of using this friction coefficient tester for safety compliance?

A: Advantages include precise, repeatable measurements, fast response (0.2 s), minimal user intervention, digital data output, multi-specimen capability, and compliance support for industrial safety standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese