Optimizing Hot Sealing Parameters for Increased Efficiency in Form-Fill-Seal Applications

50000 USD ($)/Set

Product Details:

- Features Multi-zone temperature control, Real-time curve display, Auto-sealing, Data export

- Max Height 650 mm

- Accuracy 0.5% FS

- Display Type LCD Digital Display

- Mounting Type Bench-top

- Number of Specimens 1 - 3

- Temperature Ambient to 300C

- Click to View more

X

Optimizing Hot Sealing Parameters for Increased Efficiency in Form-Fill-Seal Applications Price And Quantity

- 50000 USD ($)/Set

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

Optimizing Hot Sealing Parameters for Increased Efficiency in Form-Fill-Seal Applications Product Specifications

- Multi-zone temperature control, Real-time curve display, Auto-sealing, Data export

- 650 mm

- 0.5% FS

- 1 - 3

- Bench-top

- 5 N, 50 N, 100 N, 200 N, 500 N (optional)

- LCD Digital Display

- 0-300 mm

- 20% RH - 70% RH

- Ambient to 300C

- 10 mm/min - 500 mm/min

- 500 mm (Max)

- 50 Hz

- AC 220V, 50 Hz

- Form-Fill-Seal Applications, Flexible Packaging

- USB/RS232

- 45 kg

- <100 ms

- 6 mm

- 200 mm 15 mm

- 0.01 N

- 5 N - 500 N

- Hot Seal Strength Testing, Quality Control

- 0.5 MPa - 0.7 MPa

- 220 V AC

- 5 N to 500 N

- Semi-Automatic

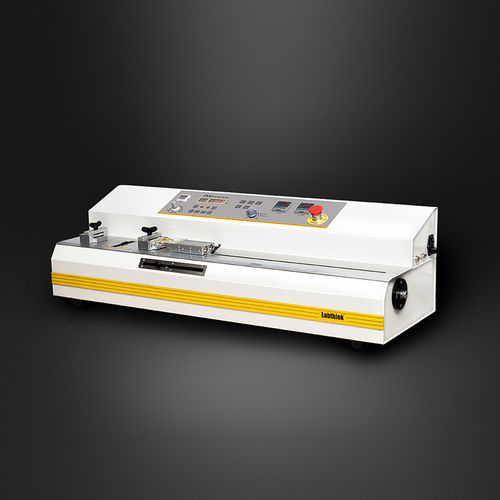

- Hot Sealing Analyzer

- Microprocessor based digital control

Product Description

Product FeaturesNote1

Multiple Test Modes in One Instrument

- Four test modes including hot tack, heat seal, peel and tensile test.

- With Digital P.I.D. temperature control system, the preset temperature can be reached in a short time without fluctuations.

- Four force test ranges and 6 testing speeds are available to meet various testing requirements

- The instrument meets the requirement for testing speed specified in standard GB/T 34445-2017

Excellent Designs & Auto Sampling

- Auto sampling for hot tack test, simplifies the testing operation and minimizes errors, ensures the uniformity of test data

- Pneumatic sample clamping system (optional)

- Automatic zeroing, error alert, overload protection and stroke protection guarantee safe operations

- Instrument can be started manually or by pedal switch. it is convenient for the operator and the anti-scald design ensures safe operations

- Components and parts of the instrument are supplied by world renowned manufacturers and have reliable performance

Computer & Instrument Controlled Operations

- Test operations can be performed on the instrument or by the software

- The instrument can be operated without a computer, easy to operate and view test data

- Data I/O ports for data export

Test StandardNote1

GB/T 34445, ASTM F1921, ASTM F2029, QB/T 2358, YBB 00122003

Applications

| Basic Applications |

|---|

|

|

|

|

| Extended Applications |

|

|

|

|

|

|

Technical SpecificationsNote2

| Specification | C632B Hot Tack Tester |

|---|---|

| Load Cell Capacity | 30 N (Standard) 50 N 100 N 200 N (Optional) |

| Force Accuracy | Indicated Value 1% (10%-100% of load cell capacity) 0.1%FS (0%-10% of load cell capacity) |

| Force Resolution | 0.01 N |

| Test Speed | 150 200 300 500 hot tack 1500mm/min, 2000mm/min |

| Specimen Width | 15 mm, 25 mm or 25.4 mm |

| Stroke | 500 mm |

| Heat Seal Temperature | Room Temperature 250C |

| Temperature Variation | 0.2C |

| Temperature Accuracy | 0.5C (Single Point Calibration) |

| Dwell Time (Heat Seal Test) | 0.1 999.9 s |

| Dwell Time (Hot Tack Test) | 0.1 999.9 s |

| Sealing Pressure | 0.05 Mpa 0.7 MPa |

| Sealing Area | 100 mm x 5 mm |

| Sealing Jaws | Double (one is silicon rubber) |

| Gas Supply | Air (Not in supply scope) |

| Gas Supply Pressure | 0.7 Mpa (101.5psi) |

| Port Size | 4 mm PU Tubing |

| Instrument Dimension | 1120 mm (L) 380 mm (W) 330 mm (H) |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Net Weight | 45 kg |

Configurations

- Standard Configurations

- Instrument, Manual Clamp, Pedal Switch, Sampling Plate, Calibration Support, 4 mm PU Tubing (2m)

- Optional Parts

- Computer, Professional Software, Pneumatic Sample Grips, Air Compressor

- Note

- 1.The gas supply port of this instrument is 4 mm PU Tubing;

2.Customers need to prepare gas supply.

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Advanced Sealing Precision for Quality Packaging

Equipped with PID-controlled heating and microprocessor-based seal pressure control, this Hot Sealing Analyzer ensures precise reproducibility for all flexible packaging materials. Accurate temperature (up to 300C) and seal jaw pressure are easily adjusted to match varied testing needs, delivering optimum hot seals and enhanced efficiency. Its multi-zone temperature control and fast response time guarantee consistent and reliable results, critical for form-fill-seal production environments.

Seamless Data Handling and Analysis

This analyzer supports comprehensive data management, including real-time curve displays, easy USB/RS232 connectivity, and data export options in Excel and PDF. Operators can analyze up to 5,000 test results, facilitating thorough process evaluations and streamlined quality assurance documentation. The equipment interfaces smoothly with Windows OS, increasing productivity and traceability for manufacturers and quality control teams.

Efficient Operation and User-Centric Design

The tool-free, minimal maintenance regimen, along with auto and manual calibration, makes this analyzer exceptionally user-friendly. Safety is prioritized with features like emergency stop and overload protection. The LCD digital display, multi-language operator interface, and bench-top mounting make integration into existing lab or production lines straightforward. With adjustable specimen capacity and wide test parameters, it adapts flexibly to diverse sealing needs.

FAQs of Optimizing Hot Sealing Parameters for Increased Efficiency in Form-Fill-Seal Applications:

Q: How does the PID-controlled heating method improve seal quality in form-fill-seal applications?

A: PID-controlled heating ensures precise and consistent temperature management across the sealing jaw, reducing fluctuations and enabling optimal heat distribution. This leads to high-quality, reliable seals on various materials such as films, laminates, and foils, which are essential for effective form-fill-seal packaging.Q: What is the process for optimizing seal pressure and temperature with this analyzer?

A: Seal pressure is digitally controlled via a microprocessor, allowing accurate adjustments based on material type and desired seal strength. You can set and monitor temperature up to 300C, while the systems real-time display and feedback ensure parameters are tuned for peak efficiency. Automatic and manual calibration options enhance reproducibility.Q: When should operators export test data, and in which formats are results available?

A: Operators typically export test data after completing testing cycles, analysis, or quality audits. Data export is supported in Excel and PDF formats, facilitating further processing, reporting, or sharing with quality control teams or clients for process validation and documentation.Q: Where can this Hot Sealing Analyzer be installed for maximum productivity?

A: Featuring a compact, bench-top design, this analyzer is suitable for quality control laboratories, production lines, or research and development settings within the flexible packaging industry. Its robust construction and safety features make it ideal for use at manufacturers, suppliers, and exporters alike.Q: What safety and maintenance features are integrated into the equipment?

A: The analyzer includes safety mechanisms such as emergency stop and overload protection. Maintenance is minimal and tool-free, with options for both automatic and manual calibration to keep the instrument operating accurately and reliably. Routine checks are easy and do not require specialized tools or skills.Q: How does the high-sensitivity load cell sensor benefit hot seal testing?

A: The integrated high-sensitivity load cell enables exceptionally precise measurement of sealing force (from 5 N to 500 N) with a resolution of 0.01 N. This ensures accurate detection of seal strength variations, helping operators optimize process parameters and improve overall product quality.Q: What are the main benefits of using this analyzer for flexible packaging applications?

A: Key benefits include enhanced seal consistency and quality, rapid test speed (10500 mm/min), wide compatibility with seal materials, easy data storage and export, multi-language display, and user-friendly, semi-automatic controls. This significantly delays potential production issues and elevates quality control standards across the packaging supply chain.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese