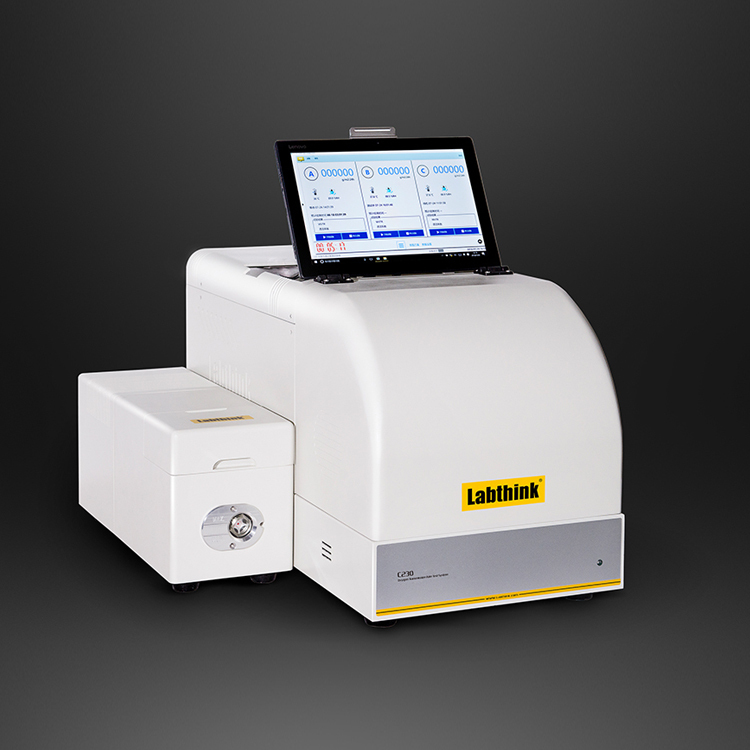

Air Permeability Tester for Assessing the Breathability of Leather Upholstery

50000 USD ($)/Set

Product Details:

- Gas Pressure 0.2 0.4 MPa

- Port Size 30 mm standard, customizable

- Test Range 1 2000 mm/s (air flow velocity)

- Features Automatic control, large LCD display, data memory, alarm system

- Humidity 45% 85% RH

- Operating Voltage 220 V

- Response Time 2 s

- Click to View more

X

Air Permeability Tester for Assessing the Breathability of Leather Upholstery Price And Quantity

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

Air Permeability Tester for Assessing the Breathability of Leather Upholstery Product Specifications

- Assessing the breathability of leather upholstery and other seat materials

- 600 mm

- 2% of reading

- 15C 35C

- 0.1 2000 mm/s

- Laboratory and industrial use

- 0.1 mm/s

- AC 220V / 50Hz

- Tabletop / Bench-top

- 42 kg

- Semi-automatic

- Adjustable (0.5 5 L/min)

- 40 mm diameter

- RS232

- 50 Hz

- 50 mm

- 0.2 0.4 MPa

- 30 mm standard, customizable

- Automatic control, large LCD display, data memory, alarm system

- 1 2000 mm/s (air flow velocity)

- 1

- 180 mm

- Digital automatic

- Digital LCD

- Single testing port

- 220 V

- 45% 85% RH

- 2 s

Product Description

Features

- This instrument is designed according to the standard requirements of global automakers.

- 2 test modes are available for customers: fix pressure difference to test flux and fix flux to test pressure difference

- High precision sensors of electronic airflow and air pressure to ensure the accuracy of test data

- The instrument is controlled by micro-computer, with LCD menu interface and PVC operation panel, which is convenient for customers to operate or view test data

- Equipped with micro-printer and standard RS232 port for easy connection with PC and data transfer

Test Principle

Method A

Providing a constant air flux going through the specimen vertically, the air permeability could be obtained by measuring the pressure difference.

Method B

Providing the constant pressure difference between two sides of the specimen, the air permeability could be obtained by measuring the air flux through specific area in the certain time.

Test Standards

TQD-G1 air permeability tester conforms to the multiple national and international standards: ISO 9237, ISO 4638, ISO 5636, GB/T 10655, GB/T 5453, GB/T 4689.22, GB/T 13764, ASTM D737, TAPPI T460, JIS P8117

Applications

TQD-G1 air permeability tester is applicable to the determination of:

| Basic Applications |

|---|

|

|

|

|

| Extended Applications |

|

Technical Specifications

| Specifications | TQD-G1 Air permeability tester |

|---|---|

| Test Range of Pressure | 0 1000 Pa |

| Test Range of Flux | 0 30 L/min |

| Specimen Size | Method A: 52 mm x 52 mm Method B12 mm D(diameter) I71 mm |

| Port Size | I8 mm PU Tubing |

| Instrument Dimension | 502 mm (L) x 334 mm (W) x 298 mm (H) |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Net Weight | 27 kg |

Configurations

- Standard Configurations

- Instrument, Micro-printer, Grips, Round Sample Cutter and Vacuum Pump from America

- Optional Parts

- Professional Software, Communication Cable and Customized Grips

- Note

- The gas supply port of the instrument is I8 mm PU tubing.

Digital Precision and Reliable Compliance

Engineered to deliver reproducible results, the Air Permeability Tester integrates intuitive digital controls, automatic operation, and strict adherence to ASTM D737 and ISO 9237. The large digital LCD simplifies monitoring test parameters, and status LEDs offer clear feedback during operation. Its robust aluminum alloy sample holder provides stability during testing, ensuring consistent and precise measurements.

Versatile Application for Upholstery and Beyond

Aimed at both laboratory and industrial use, this tester seamlessly evaluates the breathability of leather as well as other seat materials. Its single-port testing and customizable port size cater to a variety of specimen types, making it a versatile solution for exporters, manufacturers, and suppliers. The automatic memory function and RS232 interface also support efficient data management and reporting.

FAQ's of Air Permeability Tester for Assessing the Breathability of Leather Upholstery:

Q: How does the Air Permeability Tester operate to assess leather breathability?

A: This instrument measures the pressure differential and air flow passing through a leather specimen clamped in an aluminum alloy holder. The digital automatic control adjusts test speed and air flow, complying with ASTM D737 and ISO 9237 standards.Q: What materials and environments can the tester be used for?

A: While primarily designed for leather upholstery, the tester can evaluate various seat and textile materials. Suitable for laboratory and industrial applications, it operates efficiently in environments with 45-85% relative humidity and 15C-35C temperature.Q: When should I use this tester for optimal performance and results?

A: It is best utilized during quality control, research, and material development stages when accurate breathability data is needed. The system should operate within specified environmental conditions and be powered by a 220V AC supply.Q: Where can I install or mount the Air Permeability Tester?

A: The tester is designed for tabletop or benchtop mounting, making it suited for laboratories, manufacturing quality control rooms, and research facilities.Q: What is the process for conducting a test using this machine?

A: Place a 40 mm diameter specimen into the holder, configure the test parameters via the digital controls, and initiate the automatic test. The system measures and displays air permeability in real-time, storing up to 250 results for later analysis.Q: How is data displayed and managed after testing?

A: Test results are shown on a large digital LCD screen with clear readings and status indicators. Data can be stored in the internal memory and exported via the RS232 interface as needed.Q: What are the main benefits of using this Air Permeability Tester?

A: The device provides high accuracy (2%), rapid response, automatic safety features, low maintenance due to its oil-free pump, bilingual support (English/Chinese), and the ability to handle diverse testing requirements for leather and seat materials.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Gas Permeability Testers' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese