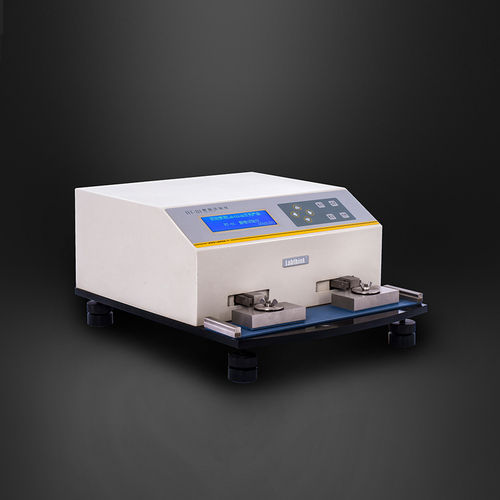

Digital Rub Tester For Printing Or Coating Layer

50000 USD ($)/Set

Product Details:

- Equipment Type Digital Rub Tester

- Power Supply AC 220V 50Hz

- Accuracy 1 cycle

- Temperature 10C 40C

- Test Range 0 99999 cycles

- Automation Grade Semi-Automatic

- Max Height 210 mm

- Click to View more

X

Digital Rub Tester For Printing Or Coating Layer Price And Quantity

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

- 1 Set

Digital Rub Tester For Printing Or Coating Layer Product Specifications

- 0.4 0.7 MPa

- LED Digital Display

- Standard test head hardness: 70 Shore A

- 50 140 mm

- 60 mm

- 50 mm

- 50 Hz

- Up to 99999 cycles

- 18 kg

- 220V AC

- 1

- Evaluation of printing, coating, label, packaging wear resistance

- 1 cycle

- Instantaneous (digital control)

- Abrasion resistance testing for printing or coating layer

- Tabletop

- 10C 40C

- 1 cycle

- AC 220V 50Hz

- Digital Rub Tester

- 0 99999 cycles

- Up to 500 g (rub head weight)

- 210 mm

- Semi-Automatic

- 43 cpm (cycles per minute)

- Digital/Touch Panel

- Touch Screen Interface

- Relative Humidity 45% - 85%

- Programmable test cycles, easy specimen mounting, digital counter

- 1/8 NPT

Product Description

Features of Ink Rub Tester

- 4 test modes of dry rub, wet rub, wet transfer, and wet smear and 4 different test speeds to meet different test requirements

- Dual stations with arc movement structure can test equivalent or distinct specimens simultaneously

- Intelligent design of power failure memory and buzzer reminding ensure the safety of test operation

- The instrument is controlled by micro-computer, with PVC operation panel, LCD and menu interface, which is convenient for users to operate or view the test data

Testing Standards

This test instrument conforms to the standard: ASTM D5264, TAPPI T830

Testing Applications

RT-01 Ink Rub Tester is applicable to the determination of abrasion resistance of:

| Basic Applications |

|---|

|

|

Technical Specifications

| Specifications | RT-01 Ink Rub Tester |

|---|---|

| Rub Pressure | 8.9 N(2lb); 17.8N(4lb) |

| Rub Speed | 21, 42, 85, 106 cpm |

| Rub Mode | Arc Reciprocating Movement |

| Rub Times | 0 999999 |

| Number of Specimens | 1 2 |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Instrument Dimension | 485 mm (L) x 390 mm (W) x 230 mm (H) |

| Net Weight | 40 kg |

Configurations

- Standard Configurations

- Instrument, 8.9N (2lb) Test Block, 17.8N (4lb) Test Block and Rubber Cushion

- Optional Parts

- Customized Test Block

Outstanding Performance and Adaptability

Engineered for rigorous abrasion testing, this digital rub tester delivers precise control with an LED digital display and touch panel operation. With flexibility in test cycle programming, quick setup within a minute, and a robust 18 kg build, it adapts seamlessly to various testing scenarios across printing, packaging, and labeling industries.

Comprehensive Testing Capability

The unit accommodates a specimen size up to 50 140 mm and supports adjustable test head weights for different abrasion scenarios. Capable of testing up to 99,999 cycles at a speed of 43 cpm, the tester ensures thorough evaluation of material endurance against rubbing forces, aiding in product quality improvement.

User-Friendly and Safe Operation

Designed for operator convenience, this rub tester features a straightforward mounting system, touch screen interface, and instant digital control. Built-in safety features like overload protection and emergency stop enhance user protection, while USB output streamlines data management for analysis and quality documentation.

FAQ's of Digital Rub Tester For Printing Or Coating Layer:

Q: How do I set up the Digital Rub Tester for use?

A: The tester is designed for quick setup, typically taking less than a minute. Simply mount your specimen, select desired settings using the digital touch panel, and attach the test head. The intuitive interface guides you through the process for fast and accurate preparation.Q: What materials and applications is this rub tester suitable for?

A: This device is ideal for assessing abrasion resistance on printed and coated surfaces, including labels, packaging materials, and coated paper, commonly used in printing, manufacturing, and packaging industries.Q: When should I perform a calibration on the rub tester?

A: The tester is factory calibrated for immediate use. Manual calibration is supported and should be performed as required by your internal quality guidelines or if you notice measurement discrepancies during testing.Q: Where can I export and analyze test data from the device?

A: Test results can be exported via the provided USB port, enabling easy transfer to a computer for in-depth analysis, quality documentation, or compliance recording.Q: What is the testing process for evaluating abrasion resistance?

A: After mounting your specimen and selecting test parameters (such as head weight and cycle count), the machine performs controlled rub cycles over a 60 mm stroke. The LED display provides instant feedback and progression tracking until test completion or the set parameter is reached.Q: How does the tester ensure user safety during operation?

A: Safety is ensured through integrated features like overload protection and an emergency stop button, minimizing risk from unexpected machine behaviors or operator mishandling.Q: What are the benefits of using this digital rub tester?

A: The tester offers fast, accurate abrasion assessment with programmable testing, easy specimen mounting, and digital data output. Its precision aids in quality assurance, improved product durability, and compliance with industry standards.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese