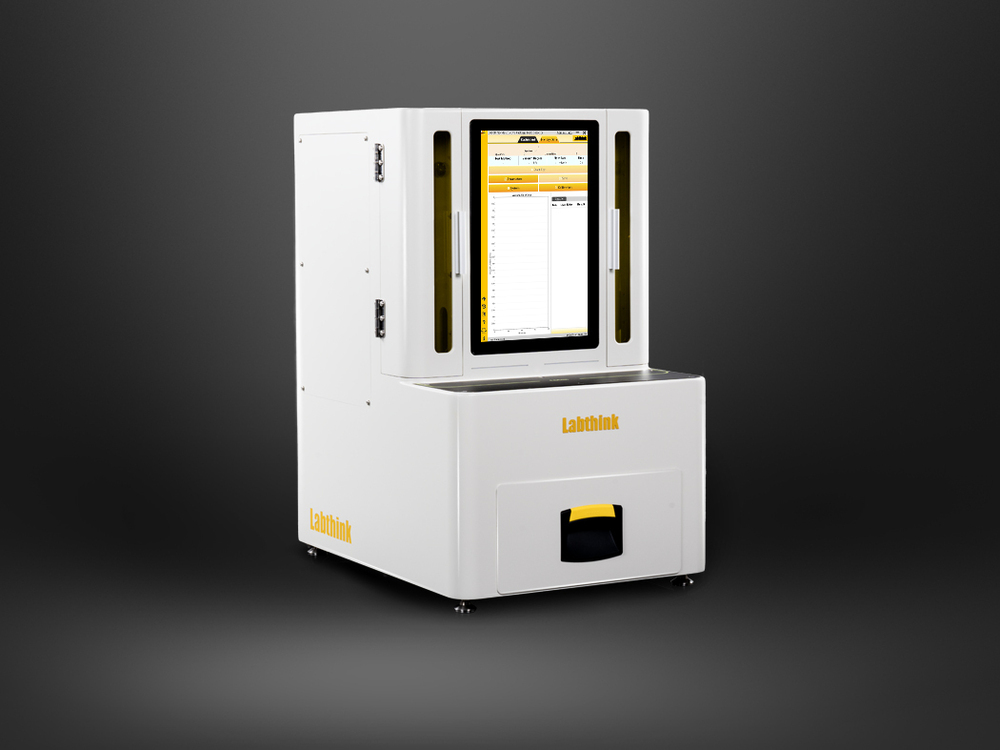

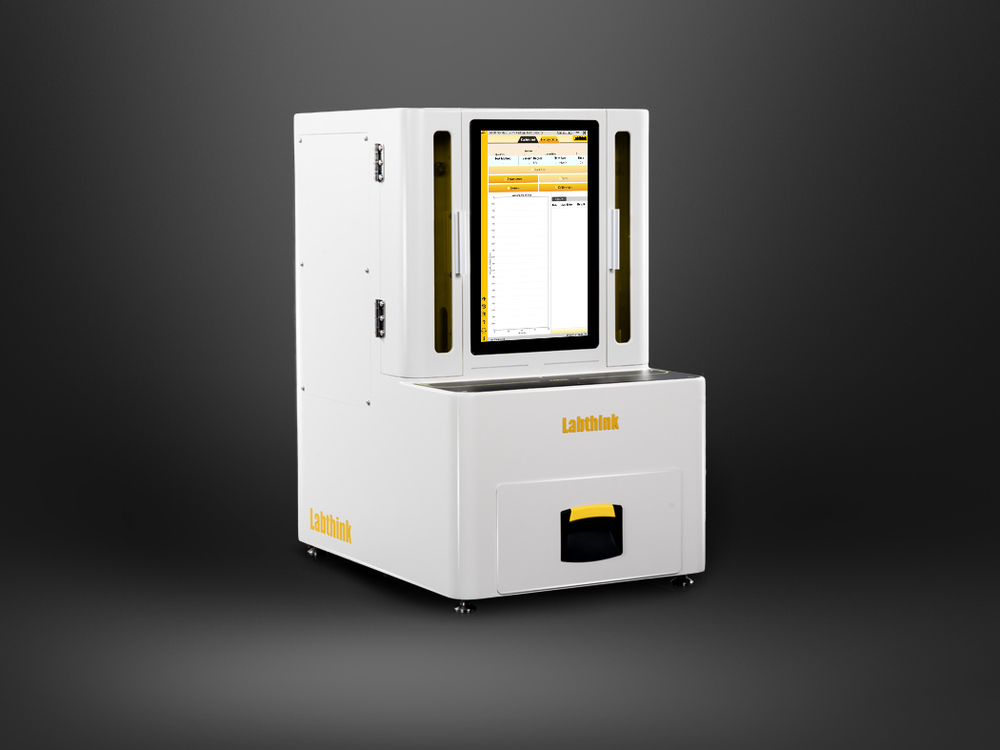

Package Leak Detection Instrument

2000.00 - 20000.00 USD ($)/Set

Product Details:

- Operating Voltage 220V AC

- Display Type Digital LCD

- Max Height 400 mm

- Humidity 0~98% RH (non-condensing)

- Port Size 6 mm

- Application Leak testing for packaging materials

- Resolution 0.1 mbar

- Click to View more

X

Package Leak Detection Instrument Price And Quantity

- 10 Set

- 2000.00 - 20000.00 USD ($)/Set

Package Leak Detection Instrument Product Specifications

- 10C - 40C

- 220V AC, 50Hz

- RS232

- Tabletop

- Customizable

- Up to 300 mm

- Digital Touch Panel

- Adjustable

- Package Leak Detection Instrument

- 1~1000 mbar

- 0-1000 mbar

- Single Chamber

- Easy operation, Fast detection, High sensitivity, Audible alarm

- 50 Hz

- 1% FS

- 0-0.9 MPa

- 2 seconds

- 0-200 mm

- Semi-automatic

- Package quality testing

- 0.1 mbar

- 1

- 0~98% RH (non-condensing)

- 25 kg

- 6 mm

- Leak testing for packaging materials

- 220V AC

- Digital LCD

- 400 mm

Package Leak Detection Instrument Trade Information

- 10 Set Per Week

- 7 Days

Product Description

Product Details:|

| Measurement Range | Three-side sealed packages, Finished Packages |

| Display Type | Digital |

| Model | LSSD-01 |

Technical Specification

| Specifications | LSSD-01 |

|---|---|

| Test Range | 1.5 ~ 600 KPa; 0.22 ~ 87.0 psi (standard) |

| 0.004 ~ 1.6 MPa; 0.58 ~ 232.1 psi (optional) | |

| Gas Injection Head | 10 mm (standard) |

| 4 mm, 1.6 mm (optional) | |

| Gas Supply Pressure | 0.5 MPa ~ 0.7 MPa (outside of supply scope) |

| Port Size | 8 mm PU Tubing |

| Instrument Dimension | 300 mm (L) x 310 mm (W) x 180 mm (H) |

| Pedestal Size | 305 mm(L) x 356 mm(W) x 325 mm(H) |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Net Weight | 23 kg |

Advanced Leak Detection Technology

By using the vacuum decay method, this instrument detects even minute leaks within packages. Its high-accuracy sensors and rapid response time provide dependable results, while the adjustable test speed and wide test range accommodate diverse packaging types. Stainless steel construction enhances durability and maintains consistent test environments.

User-Friendly Operation & Data Management

Featuring a digital touch panel for easy operation and a built-in memory for up to 100 test records, the instrument offers streamlined workflow and comprehensive traceability. The clear LCD display, customizable specimen sizes, and semi-automatic functions facilitate efficient use for operators of varying expertise.

Safety and Compliance

Safety is ensured through overpressure automatic cut-off and audible visual alarms. The instrument is calibrated annually and complies with ISO 11607 and ASTM F2338, demonstrating its compatibility with international standards. This makes it a reliable choice for businesses demanding stringent quality testing.

FAQs of Package Leak Detection Instrument:

Q: How does the Package Leak Detection Instrument identify leaks in packaging?

A: The instrument employs the vacuum decay method, reducing air pressure within the chamber and monitoring for pressure changes that indicate a leak in the specimen. This sensitive technique allows for accurate detection of even small leaks in various package types.Q: What types of packaging can be tested with this instrument?

A: It is designed to test flexible, rigid, and semi-rigid packages. The machines customizable specimen size feature and adjustable test stroke up to 200 mm support a wide array of packaging formats commonly used in industries.Q: When should the instrument be calibrated for optimal performance?

A: Annual calibration is recommended to maintain measurement accuracy and ensure compliance with ISO 11607 and ASTM F2338 standards. Regular calibration helps preserve reliability in your testing results.Q: Where is this instrument suitable for installation and use?

A: With its compact tabletop design and robust stainless steel chamber, the instrument is ideal for use in laboratories, production facilities, quality control departments, and package manufacturing environments.Q: What is the process for conducting a leak test using this equipment?

A: Users place the specimen within the chamber, set the desired parameters via the digital touch panel, and initiate the test. The instrument automatically performs the vacuum decay analysis, followed by a digital display of the results and alerts for any detected leaks.Q: How can test data be managed and retrieved from the instrument?

A: The built-in memory stores up to 100 test results, which can be accessed directly via the digital LCD. For deeper integration, the RS232 interface supports data export to external systems for further analysis or archiving.Q: What are the main benefits of using this vacuum decay leak detection instrument?

A: Key advantages include rapid and accurate leak identification, automated alarms for safety, easy operation, flexible specimen testing, and compliance with international quality standardsall contributing to improved package integrity and quality assurance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Package Leak Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese