Coulometric Method for Measuring Contact Lenses Oxygen Permeability

50000 USD ($)/Set

Product Details:

- Interface Type RS232 for data transfer

- Measuring Range 0.2 - 200 Barrer

- Application Contact lens oxygen permeability measurement

- Number of Specimens Up to 5 at a time

- Gas Pressure 1-5 psi

- Automation Grade Semi-automatic

- Max Height 350 mm

- Click to View more

X

Coulometric Method for Measuring Contact Lenses Oxygen Permeability Price And Quantity

- 50000.00 - 100000.00 USD ($)/Set

- 1 Set

- 50000 USD ($)/Set

Coulometric Method for Measuring Contact Lenses Oxygen Permeability Product Specifications

- 10-90% RH

- Real-time monitoring, automatic calibration

- Benchtop

- 220V AC, 50Hz

- Laboratory and industrial quality control

- 350 mm

- Ambient, 10-40°C

- 1-5 psi

- Semi-automatic

- Adjustable up to 60 rpm

- Up to 5 at a time

- Contact lens oxygen permeability measurement

- 0.2 - 200 Barrer

- RS232 for data transfer

- LCD digital display

- 50 Hz

- 0.01 Barrer

- 220V AC

- Standard 6 mm OD

- Diameter 12-20 mm

- <10 s

- Up to 25 mm

- 0-50 mm (variable)

- 12 kg

- ±2% of reading

- Coulometric Test Apparatus

- Single and Multi-chamber options

- 0.2 to 200 Barrer

- Microprocessor-based digital control

Product Description

Product FeaturesNote1

- Equipped with Labthink self-developed coulometric sensor conforming to ASTM D3985, intrinsic standard and no calibration is required

- Support temperature control to satisfy tests under different conditions (optional)

- Built-in high-quality stainless steel test cell with better sealing performance

- Imported manual isolation valve and flow regulator are adopted for better sealing performance and lower failure rate

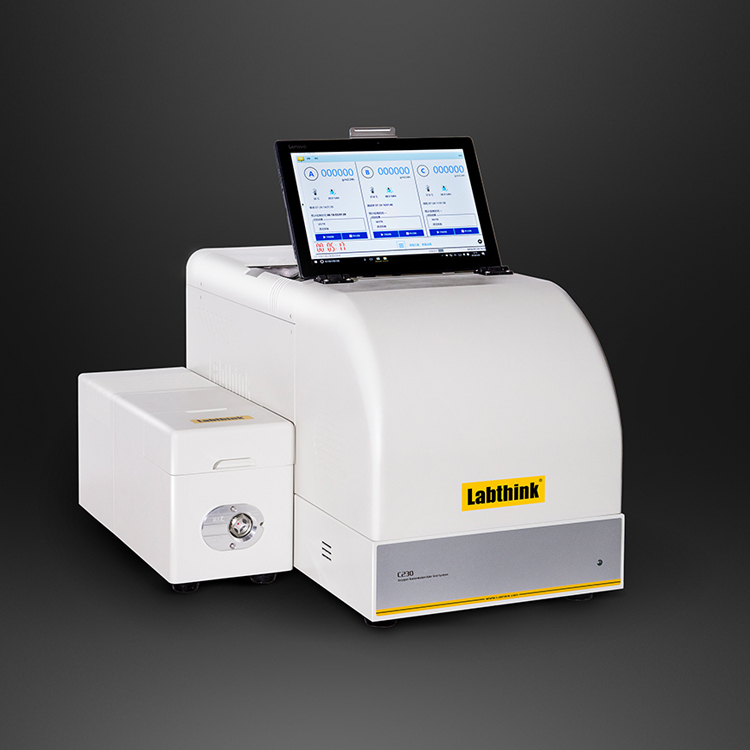

- Industrial computer appearance design, small size and fast cooling

- Reference film is provided for quick calibration

- The system adopts single-chip microcomputer control and can run independently

- The test report can be exported in common formats such as EXCEL and PDF

- Support micro printer, automatically print test data (optional)

- Equipped with RS232 data interface, which can be connected to computer software for curve analysis, data storage, report printing, etc. (optional)

- The gas purifier independently developed by Labthink can remove trace oxygen in nitrogen and provide oxygen-free carrier gas (optional).

Standard

ASTM D3985ASTM F1307GB/T 19789GB/T 31354DIN 53380-3JIS K7126-2-BYBB 00082003-2015

Applications

| Basic Applications |

|---|

|

|

|

| Extended Applications |

|

|

|

|

|

|

Technical Specifications

Table 1: Test Parameters Note1

| Parameter | Model C230H | |

|---|---|---|

| Test Range | cm3/(m2d) (Standard) | 0.01 200 |

| cc/(100in2day) | 0.0007 12.9 | |

| cm3/(pkgd)(Package) | 0.00005 1 | |

| Resolution | cm3/(m2day) | 0.001 |

| Repeatability | cm3/(m2day) | 0.01 or 2% |

| Test Temperature | C | 10 55 0.2 |

| Test Humidity | RH | O2: 0%, 5% 901%, 100% Carrier Gas: 0%, 5% 902%(optional) |

| Additional Functions | Package Test (3L Max.) | Optional |

| DataShieldTM Note2 | Optional | |

| Computer System required by GMP | Optional | |

| CFR21 Part11 | Optional | |

Table 2: Technical Specifications

| Test Chamber | 3 test chambers |

| Specimen Size | 108 mm X 108 mm |

| Specimen Thickness | 3 mm |

| Standard Test Area | 50 cm2 |

| Carrier Gas | 99.999% High-purity Nitrogen (outside of supply scope) |

| Carrier Gas Pressure | 0.28 MPa/40.6psi |

| Port Size | 1/8 inch metal tubing |

Advanced Coulometric Sensor Technology

Equipped with a high sensitivity coulometric sensor, this apparatus ensures precise oxygen permeability measurements for diverse contact lens materials. The technology minimizes noise and interference, allowing reliable evaluation of both hydrogel and silicone hydrogel lenses over a broad range of test conditions. Its automatic calibration with standard films secures consistent, traceable results every cycle.

User-Friendly Operation and Versatile Data Management

A configurable control interface and microprocessor-based digital control make operations straightforward. Data can be stored on internal memory or seamlessly exported via USB, while an RS232 interface supports integration with external systems. The Windows-compatible software delivers comprehensive analysis and easy report generation for both laboratory and industrial quality control environments.

Designed for Safety, Compliance, and Efficiency

The device is engineered with built-in pressure relief and over-temperature protection, assuring safe operation. It surpasses ISO 18369-4 and ASTM F1307 standards, making it a dependable choice for international testing requirements. Its adjustable test speed and multi-specimen capacity boost productivity without compromising measurement precision.

FAQs of Coulometric Method for Measuring Contact Lenses Oxygen Permeability:

Q: How does the coulometric sensor enhance oxygen permeability measurement for contact lenses?

A: The high sensitivity coulometric sensor provides accurate detection of oxygen transmission through contact lens materials. It operates with minimal noise and boasts rapid response times, ensuring reliable and reproducible measurements for both hydrogel and silicone hydrogel lenses.Q: What types of gases can be used in this testing apparatus?

A: This unit supports pure oxygen as well as custom oxygen/nitrogen mixtures, allowing flexible testing according to various research or quality control protocols.Q: When should calibration be performed, and how does the device manage it?

A: Calibration is conducted automatically using standard films, ensuring precise measurements for each testing session. Users can also initiate calibration cycles as part of regular quality assurance procedures or after gas mixture changes.Q: Where can this coulometric testing apparatus be utilized effectively?

A: Designed for benchtop mounting, it is ideal for laboratory and industrial settingsespecially in quality control departments of contact lens manufacturers, research facilities, and accredited testing agencies.Q: What is the process for preparing and measuring multiple specimens at once?

A: The system accommodates up to five specimens simultaneously, each placed in individual chambers. Automated controls manage gas flow, test interval, and sensor readings, streamlining the workflow for enhanced throughput.Q: How does real-time monitoring and data management benefit users?

A: Real-time monitoring with the LCD digital display allows immediate feedback during tests. The devices internal memory and USB export features facilitate secure data storage and convenient transfer to analysis systems, supporting efficient tracking and reporting of results.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'OTR/WVTR Test System' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese