Oxygen Control in Packaging for Maintaining Vaccine Potency

Product Details:

- Interface Type RS232/USB

- Port Size 6 mm

- Response Time 5 seconds

- Frequency 50 Hz

- Gas Pressure 0.1 0.6 MPa

- Features Automated testing, Data logging, Alarm system

- Hardness Standard

- Click to View more

Oxygen Control in Packaging for Maintaining Vaccine Potency Price And Quantity

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

- 1 Set

Oxygen Control in Packaging for Maintaining Vaccine Potency Product Specifications

- 0.01%

- Maintaining vaccine potency by oxygen control in packaging

- 0.1 200 mm/min adjustable

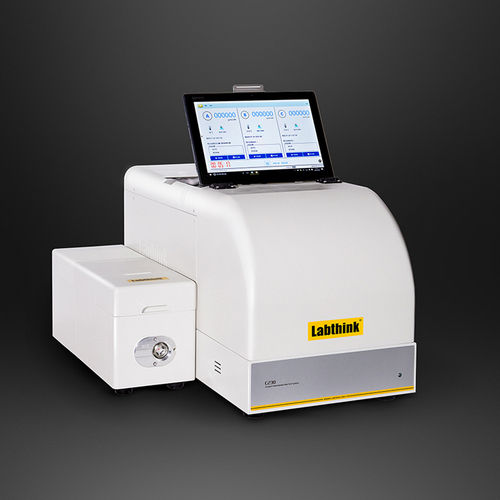

- Oxygen Controller Packaging Analyzer

- 50 Hz

- 5 seconds

- Quality control in pharmaceutical and vaccine packaging

- 6 mm

- RS232/USB

- 150 mm 100 mm

- Standard

- Automated testing, Data logging, Alarm system

- 0.1 0.6 MPa

- Bench-top

- 20% 90% RH

- Microprocessor-based digital control

- High capacity for continuous operation

- 0100% O

- 600 mm

- Digital LCD display

- 220V

- 700 mm

- 0.5%

- 13

- Automatic

- 0.01~2.0 atm

- 22 kg

- 300 mm

- 5C 45C

- AC 220V 10%, 50Hz

Product Description

Product FeaturesNote1

- The new ceramic oxygen sensor developed by Labthink has the characteristics of high precision and good repeatability.

- Ceramic oxygen sensor is non consumption type and has long service life.

- PC material operation panel, menu interface, LCD display, easy to operate and view the results.

- The system supports Chinese and English bilingual operating environment to meet the needs of different language users.

- The microcomputer control system can analyze and process the test data and output the report.

- It is easy to print the test results at any time with the embedded micro printer.

- The system has built-in data storage to meet the needs of large amount of data storage.

- Portable, easy to use in laboratory or production sites.

- Equipped with RS232 interface and professional software, which convenient for computer connection and data import and export.

Test Principle

The gas in the sample is pumped into the sensor through the vacuum pump, and the sensor outputs the real time current and voltage signals of O2 and CO2 (optional) concentration of the gas in the sample. The instrument calculates the content of O2 and CO2 (optional) in the gas by obtaining the current and voltage signal output by the sensor. After reaching the requirements for ending the tests, the tests stop, and the instrument records the concentration of O2 and CO2 (optional) in the gas tested in the sample.

Test Applications

| Basic Applications |

|---|

|

|

| Extended Applications |

|

Technical SpecificationsNote2

| Items | Parameters | |

|---|---|---|

| Type of Gas Measured | O2 (Standard) | CO2 (optional) |

| Measuring Range | 0.2%i21% | 2%i100% |

| Measurement Accuracy | 0.2% | 2% |

| Sample Size | 5ml (standard atmospheric pressure) | 20ml (standard atmospheric pressure) |

| Dimensions | 350mm (L) 330mm(W) 200mm(H) | |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz | |

| Net Weight | 5.5 kg | |

Product Configuration Note 1

| Standard Configuration | Mainframe, micro printer, sampling needle, filter and gasket |

|---|---|

| Options | CO2 sensor, professional software, communication cable, hard packaging sampler, underwater sampling device |

Note 1: The product functions, reference standards and configuration information are subject to the specific notes in the "Technical Parameters".

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory according to the requirements and conditions of relevant laboratory environmental standards.

Advanced Oxygen Monitoring for Vaccine Integrity

The equipment delivers precise oxygen control essential for sustaining vaccine potency during packaging. By leveraging a high-sensitivity electrochemical sensor, it identifies minute changes in oxygen concentration, ensuring the internal atmosphere is strictly regulated. Automated and manual calibration modes, coupled with robust data storage, help meet the strictest regulatory requirements while simplifying operation across diverse packaging materials like plastic, glass, and composite films.

Streamlined Quality Assurance and Data Management

The analyzer integrates with laboratory workflows through Ethernet, wireless, RS232, and USB connectivity. Its user-friendly digital LCD interface supports multiple languages, enhancing usability for international teams. Automated data logging for up to 10,000 test records, real-time alarms, and visual/audio indicators streamline quality assurance, helping operators catch anomalies early and maintain compliance with CE and ISO 9001 standards.

FAQ's of Oxygen Control in Packaging for Maintaining Vaccine Potency:

Q: How does the Oxygen Controller Packaging Analyzer maintain vaccine potency during packaging?

A: This equipment ensures optimal vaccine potency by precisely regulating and monitoring oxygen concentration inside packaging. By utilizing its electrochemical oxygen sensor, it accurately measures oxygen from 0% to 100%, preventing oxidative damage and preserving vaccine efficacy throughout the supply chain.Q: What is the process for measuring and controlling oxygen levels with this analyzer?

A: The analyzer automatically samples oxygen concentrations in packaging materials via its electrochemical sensor. It offers both automatic and manual calibration methods. Operators can set desired oxygen thresholds, and the device will trigger audio/visual alarms if these are exceeded. Data is logged for ongoing analysis and compliance reporting.Q: Where is this device typically used and what packaging materials are compatible?

A: This analyzer is used in cleanroom and laboratory settings-ideal environments for vaccine and pharmaceutical packaging. It is compatible with a wide variety of packaging materials including plastic, glass, and composite films, making it versatile for many pharmaceutical and biotechnology applications.Q: When should calibration be performed on the Oxygen Controller Packaging Analyzer?

A: Calibration should be conducted routinely as part of standard quality practices or whenever accuracy checks indicate a deviation. The analyzer supports both automated scheduled calibration and manual triggering, ensuring continuous accuracy without interrupting workflow.Q: How does the alarm system enhance safety and product quality?

A: The integrated alarm system provides immediate audio and visual alerts if oxygen levels breach preset thresholds. This rapid notification allows operators to act swiftly, minimizing the risk of compromised vaccine potency due to oxygen exposure.Q: What benefits does the data logging feature offer to users?

A: With a storage capacity of up to 10,000 test records, the data logging system facilitates traceability, compliance, and ongoing quality improvement. It aids in audit preparation, provides insights for process optimization, and ensures reliable documentation for regulatory bodies.Q: Why is multi-language interface support important for this analyzer?

A: Multi-language support makes the analyzer accessible to global user bases, reducing training barriers and minimizing errors in multicultural laboratory environments. This ensures consistently high-quality results, regardless of the operator's native language.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese