Testing for Friction Reduction in Manufacturing Processes Comes with Economic Benefits

50000 USD ($)/Set

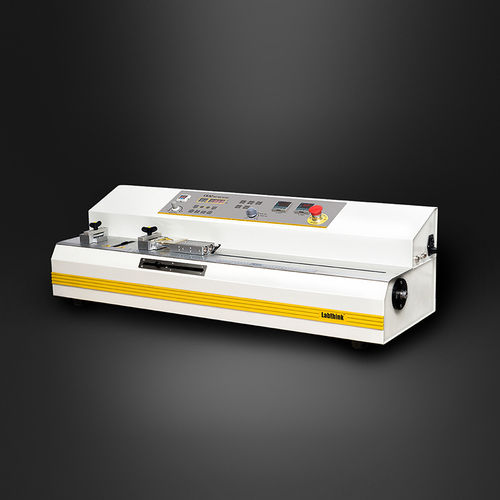

Product Details:

- Operating Voltage 220 V AC

- Mounting Type Floor/Benchtop

- Interface Type USB/RS232

- Display Type Digital Display

- Frequency 50/60 Hz

- Gas Pressure 0.50.8 MPa

- Port Size 1/4 NPT

- Click to View more

X

Testing for Friction Reduction in Manufacturing Processes Comes with Economic Benefits Price And Quantity

- 50000 USD ($)/Set

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

Testing for Friction Reduction in Manufacturing Processes Comes with Economic Benefits Product Specifications

- 0500 N

- 0.1 N

- 50 x 200 mm

- < 2 s

- Up to 4

- Evaluation of friction properties in manufacturing processes

- 1545C

- 0500 N

- 145 kg

- Economic Benefits, Repeatable Testing, Modular Design, Safety Interlocks

- 1300 mm

- Semi-Automatic

- 2090% RH

- AC 220V 10%, 50/60 Hz

- 5-300 mm/min (Adjustable)

- 0.5% of reading

- 50 mm

- Floor/Benchtop

- 220 V AC

- Digital/Manual

- 600 mm

- 50/60 Hz

- 500 N

- 0.50.8 MPa

- 1/4 NPT

- USB/RS232

- Industrial Quality Control, R&D

- Digital Display

Product Description

Features

- Static and kinetic coefficients of friction can be tested for each specimen

- This instrument conforms to multiple standards of ISO, ASTM and GB and the user could select testing methods as required

- Test speed could be preset and adjusted by the users as required

- Sled of specific weight could be customized

- The sliding plane and the sled are treated by degaussing and remanence detection which effectively reduce the system error

- Top quality parts and components made by world famous brands are used to ensure reliable overall product performance

- The instrument is controlled by micro-computer with LCD display, PVC operation panel and menu interface

- Professional operating software support statistical analysis of single specimen, group specimens, superposition analysis of test curves and historical data comparison functions

- Equipped with RS232 port and micro printer port which is convenient to the data transmission and PC connection

- Supports LystemTM Lab Data Sharing System for uniform and systematic data management

Standards

This instrument conforms to various national and international standards:

ISO 8295, ASTM D1894, TAPPI T816, GB 10006

Applications

| Basic Applications |

|---|

|

|

|

|

|

|

| Extended Applications |

|

|

|

|

|

|

|

|

Technical Specifications

| Specifications | MXD-02 Coefficient of Friction Tester |

|---|---|

| Capacity Range | 0 5 N |

| Accuracy | 0.5% FS |

| Stroke | 70 mm, 150 mm |

| Mass of Sled | 200 g (Standard) |

| Sled of specific weight could be customized | |

| Test Speed | 100 mm/min, 150 mm/min |

| Test speed could be adjusted | |

| Environment Condition | Temperature: 232C |

| Humidity: 20%RH 70%RH | |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Instrument Dimension | 630 mm (L) x 360 mm (W) x 230 mm (H) |

| Net Weight | 33 kg |

Configurations

- Standard Configurations

- Instrument, Micro Printer and Sled of 200g

- Optional Parts

- Professional Software, Communication Cable and Customized Sled of 500g

Comprehensive Friction Testing for Manufacturing Efficiency

Our Friction Reduction Testing Machine provides a precise and reliable solution for analyzing the frictional behavior of diverse materials. With automated calibration options and internal/external lubrication capabilities, it supports both quality assurance and innovation in industrial applications. Its digital display, large data storage, and modular design enable seamless integration into your workflow, while advanced safety features ensure user protection during every test cycle.

Versatile Design for Varied Testing Needs

Engineered to handle up to four specimens simultaneously, this machine accommodates a wide range of sample types and testing parameters. Adjustable speeds, stroke, and a broad test load range make it suitable for comprehensive research and production monitoring. Its intuitive touch keypad and digital/manual control modes provide flexibility, empowering operators for efficient, repeatable testing in manufacturing environments.

FAQ's of Testing for Friction Reduction in Manufacturing Processes Comes with Economic Benefits:

Q: How does this friction reduction testing machine contribute to economic benefits in manufacturing?

A: By accurately measuring friction properties, the machine helps manufacturers identify effective lubrication and material combinations, improving equipment lifespan and product quality. This leads to reduced maintenance costs, lower downtime, and optimized manufacturing processes, resulting in significant cost savings over time.Q: What materials can be tested with this equipment?

A: This machine is compatible with a variety of materials, including metals, polymers, and composites. Its robust design and adjustable test parameters make it suitable for a wide spectrum of industrial applications.Q: When is it advisable to perform regular friction reduction testing?

A: Regular friction testing is recommended during new material development, upon changes in raw material supplies, or periodically as part of quality control protocols. Consistent testing ensures ongoing product reliability and process efficiency.Q: Where should the machine be installed for optimal performance?

A: The equipment should be placed in a stable, dust-free environment with ambient temperature between 15-45C and humidity ranging from 20-90% RH. Ensure sufficient space (dimensions: 1250 x 620 x 1300 mm) and access to a reliable AC 220V 10% power supply.Q: What is the testing process using this system?

A: Operators can select either sliding or reciprocating friction tests via the digital display and touch keypad. The machine handles up to four specimens, allows customizable settings for speed, stroke, and lubrication, and stores up to 1000 test sets. Data can be exported through USB or RS232 interfaces for further analysis.Q: How is safety ensured during usage of the machine?

A: Safety measures include an emergency stop feature, overload protection, and safety interlocks-all designed to protect users and prevent equipment damage during operation.Q: What are the usage scenarios for this friction reduction testing machine?

A: The machine is widely used in industrial quality control, research and development, and material innovation initiatives. Its adaptability supports both routine production checks and advanced R&D investigations for exporters, manufacturers, and suppliers.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese