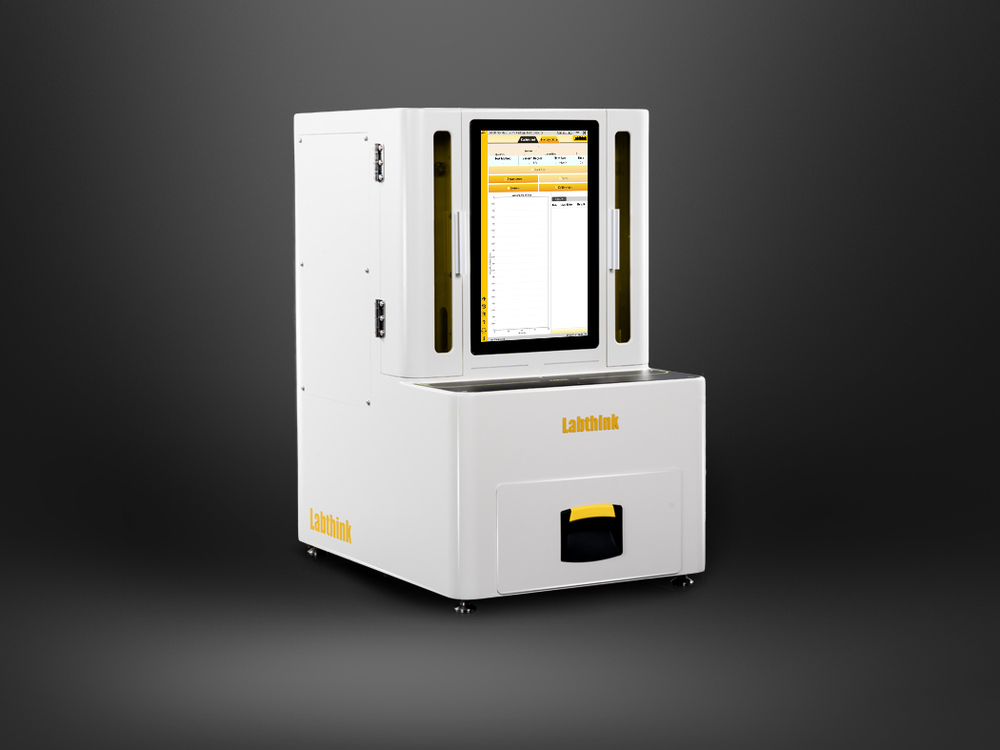

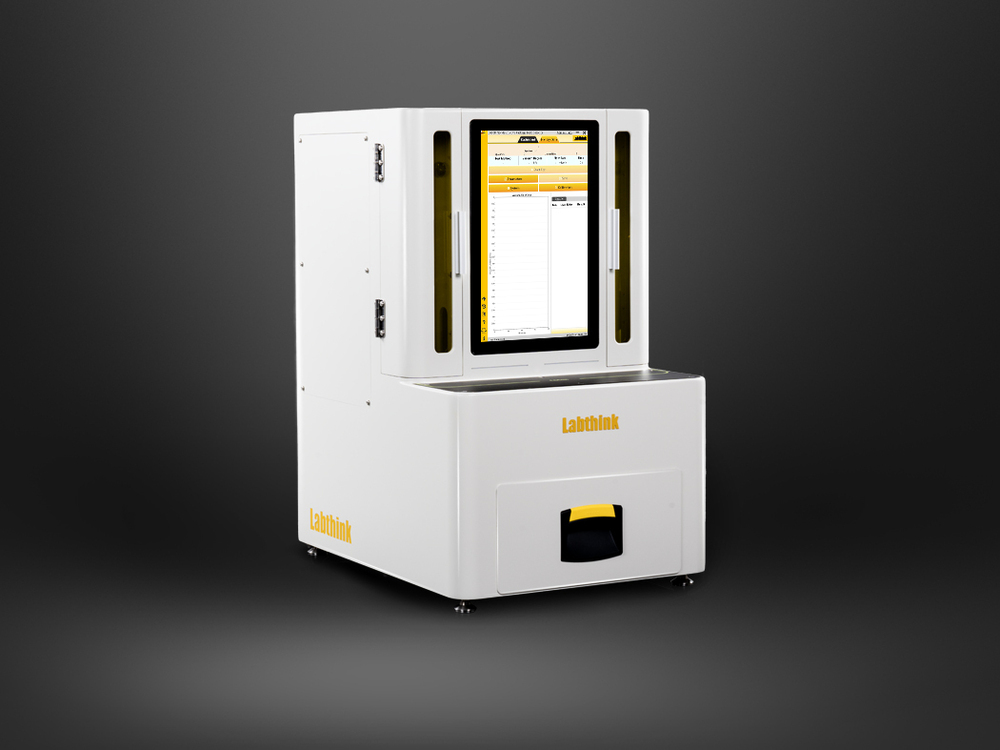

Nondestructive Leak Detector for Packages by Vacuum Decay Method

2599.0 USD ($)/Set

Product Details:

- Mounting Type Bench-top

- Port Size 1/4 inch NPT

- Frequency 50Hz

- Measuring Range 0.11000 mbar

- Features Nondestructive, automatic data logging, user-friendly interface

- Resolution 0.01 mbar

- Accuracy 1% FS

- Click to View more

X

Nondestructive Leak Detector for Packages by Vacuum Decay Method Price And Quantity

- 2599.0 USD ($)/Set

- 1 Set

- 25000.00 - 120000.00 USD ($)/Set

Nondestructive Leak Detector for Packages by Vacuum Decay Method Product Specifications

- Single or multiple (customizable)

- 100 mm (sample chamber)

- Up to 300 mm

- 10C40C

- 220V AC

- Leak tightness test for sealed packages

- RS232/USB

- Up to 300 300 100 mm

- Automatic

- Automatic microprocessor controlled

- 1 sec

- AC 220V 10% 50Hz

- 0.40.7 MPa

- 20%80% RH (non-condensing)

- Nondestructive leak detector

- 55 kg

- Digital LCD display

- 0.11000 mbar

- 1% FS

- Nondestructive, automatic data logging, user-friendly interface

- 0.01 mbar

- Laboratory and industrial QC

- Volume chamber up to 8L

- up to 60 tests/hour

- 01000 mbar

- 1/4 inch NPT

- Bench-top

- Adjustable, up to 200 mm

- 50Hz

Product Description

Non-destructive Leak Detector with vacuum decay method is specialized in the detection of leaks in ampoule, vial, injection bottle, freeze-dried powder injection bottle and pre-filled package.This test instrument conforms to many national and international standards:

ASTM F2338, USP1207

| Features: 1. Based on International standards ASTM F2338, YY-T 0681.18, and USP<1207> 2. Can realize continuous test of 20 to 120 samples. 3. Two Technologies available: Vacuum Decay and Pressure Decay 4. Achieve a higher test repetition of 1um 5. Target vacuum degree can be set freely |

| Technical Parametersi14 1. Testing Range: 3i8umigreat leakage 2. Detection Lower Limit: 3um 3. Sample Quantity: 20120 pieces 4. Resolution: 0.1um 5. Repeatability: 1um 6. Sample Size: I45 mm80mm |

| Principle: The sample is placed in the sample feeder and automatically delivered into the test cell. The leak rate and other results can be calculated and obtained by analyzing pressure changes measured by the sensor. |

Advanced Vacuum Decay Testing

Employing the Vacuum Decay Method, this leak detector offers highly sensitive, nondestructive testing for sealed packages. The transparent acrylic chamber allows clear observation while maintaining safety and integrity. This method supports both manual and automatic processes, enabling users to tailor tests to specific requirements and ensuring consistent, reliable results for package leak tightness.

Comprehensive Data Management

With automatic data logging capabilities, the device stores up to 10,000 test records. Users benefit from detailed historical data, which aids in traceability and compliance. The digital LCD display and selectable language options (English, Chinese, others on request) make operation intuitive for diverse environments. Interface connectivity via RS232/USB enables seamless integration with existing laboratory and QC systems.

Reliability and Compliance

Engineered to meet international standards (ASTM F2338, ISO 11607), this detector assures high accuracy (1% FS) and fast response times (1 sec). Its visual and audible alarm system provides immediate notification upon leakage detection. The robust bench-top design, with customizable specimen size and chamber capacity, suits a variety of package types and testing needs in quality assurance applications.

FAQ's of Nondestructive Leak Detector for Packages by Vacuum Decay Method:

Q: How does the Vacuum Decay Method detect leaks in sealed packages?

A: The Vacuum Decay Method works by creating a vacuum inside the high-strength transparent acrylic chamber. The device then monitors the pressure for any decay. If air from a leaky package enters the chamber, the pressure rises, signaling a leak. This process is nondestructive, preserving the integrity of tested packages while providing up to 0.1 mbar sensitivity.Q: What records does the device store and how can they be accessed?

A: Up to 10,000 test records are automatically logged by the detector. Data can be accessed via the digital LCD display, and external connectivity is provided through RS232 or USB ports for convenient download and analysis. This ensures complete traceability and efficient record management for quality control purposes.Q: When should calibration be performed on the leak detector?

A: Calibration can be done internally or externally, based on quality protocols or usage frequency. It is recommended to calibrate regularly, especially before critical testing sessions, to maintain accuracy within 1% FS of the measuring range. Calibration helps ensure reliable performance and compliance with international standards.Q: Where is this device best used for optimal results?

A: The leak detector is suitable for laboratory environments and industrial quality control stations. Its bench-top design allows placement on flat surfaces for routine testing. It is ideal for exporters, manufacturers, and suppliers requiring reliable leak tightness verification for various sealed package types.Q: What is the process for conducting a test with this equipment?

A: Place the specimen (up to 300 300 100 mm) inside the vacuum chamber. Select the desired test mode-manual or automatic. Initiate the test using the user-friendly interface. The detector measures pressure change over the test stroke (up to 200 mm), alerts for leaks using visual and audible alarms, and automatically logs results in the system.Q: How does using this leak detector benefit quality control operations?

A: Implementing this leak detector enhances overall package integrity verification by providing rapid, accurate, and nondestructive leak testing. Its automatic data logging, adjustable testing processes, and visual/audible alerts streamline quality control procedures, reduce product waste, and contribute to international compliance-all vital for exporters and manufacturers.Q: Can the language options of the interface be customized for different users?

A: Yes, the device supports multiple language options, including English and Chinese by default. Other languages can be requested, making it adaptable to different regional and international user requirements. This ensures ease of use across global quality control teams.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Package Leak Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese