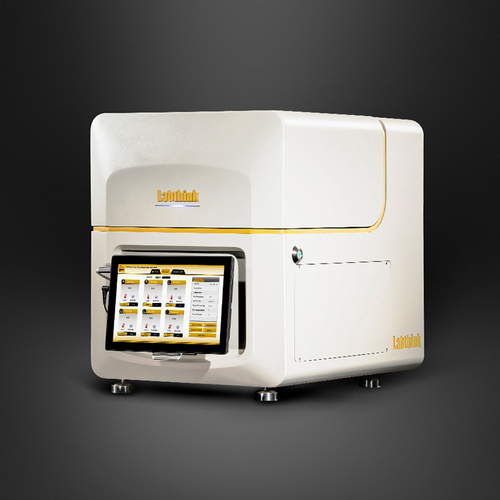

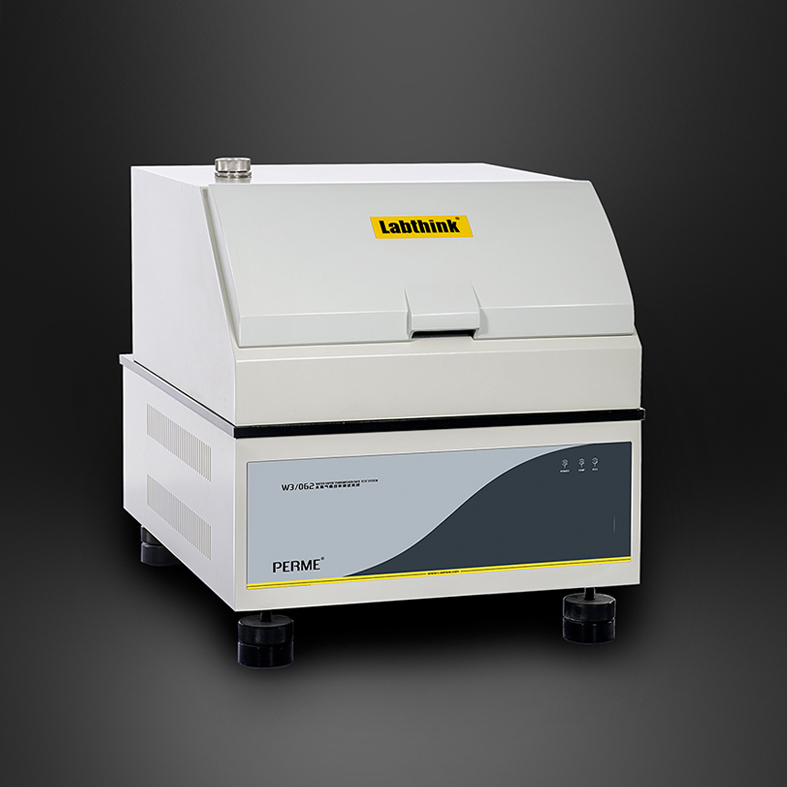

Biodegradable packaging films permeability tester

Product Details:

- Response Time 5 seconds

- Max Height 500 mm

- Resolution 0.001 g/m24h

- Measuring Range 0.01 1000 g/m24h; 0.01 5000 cc/m24h

- Interface Type USB / RS232

- Features Programmable parameters, Auto-calibration, Data storage

- Gas Pressure 0.1 0.5 MPa

- Click to View more

Biodegradable packaging films permeability tester Price And Quantity

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

Biodegradable packaging films permeability tester Product Specifications

- 10% 98% RH (controllable)

- Automatic

- AC 220V, 50Hz

- 50/60 Hz

- Multi-sample chamber

- 220V AC

- Approx. 70 kg

- Digital LCD / Touch Screen

- 108 mm diameter

- Testing water vapor and gas permeability of biodegradable packaging films

- Bench-top

- 10C 60C (programmable)

- 0.01 1000 g/m24h (H2O), 0.01 5000 cc/m24h (O2/CO2)

- Permeability Tester

- Standard 1/4 inch

- 0.1 0.5 MPa

- 1% of reading

- 1-3 (simultaneous testing)

- Programmable parameters, Auto-calibration, Data storage

- USB / RS232

- 100 mm

- Laboratory & Industrial

- 0.01 1000 g/m24h; 0.01 5000 cc/m24h

- 0.001 g/m24h

- 500 mm

- 0 350 mm

- 5 seconds

- Microcomputer/Touch Panel

- 0.01 10 mm/min (adjustable)

Product Description

Product FeaturesNote1

Infrared sensor

- Equipped with Labthink patented infrared sensor, features a wider test range.

- Designed conforming to ASTM F1249.

- Ultra-long service life, non-consumable type.

- Embedded with over-range warning and automatic protection function.

Accurate data

- Brand new dome design test chamber and 360 air circulation constant temperature technology ensures better temperature stability.

- The test chamber is equipped with a high-precision humidity sensor to monitor and record humidity changes in real time.

- The control of velocity, temperature and relative humidity is automated to realize higher accuracy.

High Efficiency

- Six independent test cells with a standard area of 50cm2, three times the number of test cells in traditional oxygen permeability testing instruments

- Six specimens can be tested simultaneously under the same testing condition, delivering independent test result.

- Within the same time duration, the number of tested specimens is increased from 2 to 6.

- Automatic specimen clamping saves time and effort. The clamping force is consistent, resulting in better air tightness.

Intelligent control

- 12 touch-screen tablet powered by WindowsTM 10 operating system makes the operation simpler and more convenient.

- Automatic test mode requires only inputting temperature and humidity, one click startup, the test is fully automated.

- Intelligent test chamber hood automatically opens and closes with sound and light alert.

Safe and reliable

- System security -- Built-in Labthink's unique high-end industrial computer prevents system failures caused by computer viruses, ensures operational reliability and data storage security.

- Operation safety-- Equipped with various intelligent sensors which give sound and light alert to ensure safe operation.

- Performance reliabilitythe instrument adopts components of global renowned brands, to ensure stable and reliable performance.

Space saving

- The width of the instrument is only 1/3 of the traditional six-cell instrument, saving space for a laboratory.

Powerful functions

- Professional test mode provides flexible and diverse control options to meet various needs of scientific research.

- The system provides oxygen transmission rate curve, oxygen transmission coefficient curve, temperature curve, and humidity curve.

- Ultra-wide test range to meet the barrier test of various materials (customize).

- Ultra-wide temperature range to meet the barrier test under different extreme temperatures (optional).

Test Principle

The pre-conditioned specimen is clamped in the test cell, nitrogen with stable relative humidity flows on one side of the specimen while a stream of dry nitrogen flows on the other side. Due to the humidity difference, water vapor permeates through the specimen from the high humidity side into the low humidity side, and is carried to the infrared sensor by the dry nitrogen flow. By analyzing the electrical signals generated by the water vapor, the sensor calculates the water vapor concentration and the water vapor transmission rate.

Standard

ASTM F1249aISO 15106-2aGB/T 26253aJIS K7129aYBB00092003-2015

Applications

| Applications |

|---|

|

|

Technical Specifications

Table 1: Test Parameters Note2

| Parameters/Model | C306H | |

|---|---|---|

| Test range | g/(m2day) (Standard area 50cm2) | 0.02i40 |

| g/(m2day) (MASK area 5cm2) | 0.2i400i14Optionali14 | |

| g/(m2day) (MASK area 1cm2) | 1i2000i14Optionali14 | |

| Resolution | g/(m2day) | 0.0001 |

| Repeatability | g/(m2day) | 0.02 or 2%i14take the greater |

| Test Temperature | 15i50i145i60i14Optionali14 | |

| Temperature fluctuation | 0.15 | |

| Test Humidity | %RHi14Within standard temperature rangei14 | 100%i145i902% |

| Additional Functions | DataShieldTM note3 | Optional |

| GMP Computer System requirement | Optional | |

| CFR21Part11 | Optional | |

Table 2: Technical Specifications

| Test Cell | 6 Cells |

|---|---|

| Specimen Size | 4.6 x 4.6i1411.7cm11.7cmi14 |

| Specimen Thickness | 120 Mili143mmi14 |

| Standard test area | 50cm2 |

| Carrier Gas | 99.999% High purity nitrogen(Outside of supply scope) |

| Carrier Gas Pressure | 40.6 PSI / 280 kPa |

| Port Size | 1/8 Metal tube |

| Instrument Dimension | 23.6 H x 19.2 W x 25.9 D (60cm 49cm 66cm) |

| Power Supply | 120VAC10% 60Hz / 220VAC10% 50Hzi14one of twoi14 |

| Net Weight | 220Lbsi14100kgi14 |

Table 3: Product Configuration

| Standard Configuration | Instrument mainframe, tablet, sampler, vacuum grease, I6 mm PU tubing |

|---|---|

| Optional Parts | Air compressor, CFR21Part11, GMP Computer System Requirement, DataShieldTM note3 |

| Note | The gas supply port of the instrument is I6 mm PU tubingi14pressure79.7 PSI / 550 kPai14, customers need to prepare gas supply. |

Note 1: The described product functions are subject to the specification in "Technical Parameters".

Note 2: The parameters in the table are measured in Labthink laboratory by professional operators according to the requirements and conditions stapulated in laboratory environmental standards.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

Reliable Compliance and Precision

Test your biodegradable packaging films with confidence, meeting international standards including ASTM E96, ISO 15106, and DIN 53122. The system's certified electrochemical sensors offer remarkable accuracy and speed, delivering data with a 1% reading accuracy and a resolution of 0.001 g/m224h. Built-in auto-calibration and safety features further enhance the reliability and reproducibility of test results, optimizing quality assurance for laboratories and manufacturers.

Advanced Automation and Data Management

This permeability tester is engineered with advanced automation-such as programmable parameters, automatic calibration, and multi-level password protection-streamlining the testing process. Data management is simplified through on-board memory for up to 10,000 records, USB export, wireless connectivity, and seamless integration with Windows/PC analysis software, enabling thorough record-keeping and efficient workflow.

Versatile and User-Friendly Operation

Accommodating biodegradable films, plastic films, paper, and coated foils, the tester can simultaneously evaluate up to three specimens. The touch screen interface and microcomputer control make operation intuitive, while robust sample holders of stainless steel/PTFE ensure compatibility and durability. Adjustable sampling and test speed allow for customization across a wide measuring range, making this instrument ideal for both research and industrial applications.

FAQ's of Biodegradable packaging films permeability tester:

Q: How does the permeability tester ensure accuracy when testing biodegradable packaging films?

A: This tester utilizes highly sensitive electrolytic sensors for water vapor and coulometric sensors for oxygen, providing an accuracy of 1% of reading and a resolution of 0.001 g/m224h. Automatic calibration with built-in standards maintains precision across varied testing conditions.Q: What international standards does this instrument comply with?

A: The machine is compliant with ASTM E96, ISO 15106, and DIN 53122, ensuring its acceptance and reliability for routine testing in accordance with globally recognized methodologies.Q: When should automatic calibration be performed on the tester?

A: Automatic calibration is recommended as part of routine start-up procedures and prior to critical test series, thanks to a built-in system that verifies and adjusts sensor performance to maintain measurement integrity.Q: Where can the permeability tester be used and installed?

A: This benchtop automatic equipment is suitable for both laboratory and industrial environments, with optimal operation in ambient conditions of 5C to 35C and up to 85% relative humidity (non-condensing).Q: What is the process for initiating a permeability test on this equipment?

A: Place prepared specimens (up to three, diameter 108 mm) into the multi-sample chamber, set desired parameters via the digital LCD/touch screen interface, and start the test. The system offers automatic leak detection and programmable test speed and conditions for accurate and efficient measurement.Q: How is data from the tester managed and exported?

A: Test results are stored on-board (up to 10,000 records) and can be exported via USB or wirelessly. The tester is compatible with Windows/PC-based analysis software for thorough post-test evaluation and report generation.Q: What are the main benefits of using this permeability tester for biodegradable packaging films?

A: Key advantages include industry-compliant accuracy, automated processes to streamline workflow, multi-sample testing, comprehensive safety systems, and versatile data management, all of which support efficient, reliable research and quality control.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'OTR/WVTR Test System' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese