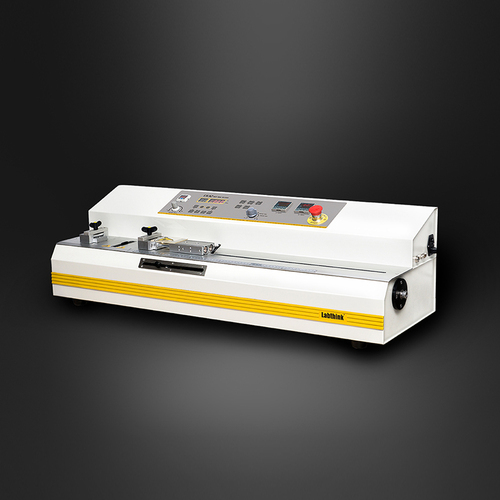

Flexible Pouches packaging heat seal strength tester

50000 USD ($)/Set

Product Details:

- Power Supply AC 220V, 50Hz

- Gas Pressure 0.6 MPa (6 kgf/cm)

- Humidity 20%70% RH operating range

- Automation Grade Automatic

- Max Height 250 mm (specimen opening)

- Features Peak hold, Real-time data, Automatic calculation, Data recall

- Measuring Range 0.01 N to 100 N

- Click to View more

X

Flexible Pouches packaging heat seal strength tester Price And Quantity

- 1 Set

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

Flexible Pouches packaging heat seal strength tester Product Specifications

- 200 mm/min (standard), adjustable

- 0.6 MPa (6 kgf/cm)

- AC 220V, 50Hz

- 0~30 mm

- RS232/USB

- Digital Heat Seal Strength Tester

- Bench-top

- Measurement of seal strength in flexible packaging

- 100 N

- 0.01 N to 100 N

- Automatic

- 250 mm (specimen opening)

- Peak hold, Real-time data, Automatic calculation, Data recall

- 20%70% RH operating range

- Microprocessor Based Control

- Large LCD digital display

- 6 mm pneumatic

- 0~100 N (can be customized)

- 42 kg

- 220V AC 10%, 50Hz

- 70 mm

- Determination of heat seal bond strength of flexible pouches/packaging materials

- <200 ms

- 50Hz

- 1% of Reading

- 0.01 N

- Single or Parallel (up to 5) specimens at once

- 100 mm x 100 mm (customizable)

- Ambient, up to 50C

Product Description

Product FeaturesNote1

Constant Pressure & Automated Sample Feeding

- Automatic pressure control technology manages the pressure fluctuation within 0.005MPa

- The test pressure can be set through the program without manual adjustment

- Automatic sample feeding technology to ensure the accuracy of test time

- Upper and lower sealing jaws with metal surfaces can obtain more authentic thermal tack performance

- Digital P.I.D temperature control technology enables the tester to reach the set temperature quickly, effectively avoids temperature fluctuations

Safety Design & Automatic Sample Clamping

- The overall protective cover is designed to prevent hand pinching, scalding and collision, making sure the operation is safer

- Preload fixtures are convenient for sample clamping.

- Pneumatic sample clamping saves time and effort, with consistent clamping force and better sealing efficiency.

- Observation window for clear monitoring of the test process

Intelligent Control & Reliable Performance

- The 7 Inch industrial level Touch panel control for easier operation.

- Sensor static design, reducing force fluctuation

- AC servo system, more stable high-speed operation

- Global sourced core components ensure low failure rate and long service life

- The self-detection function warns of over heat and over limit.

- Support display of multiple units in MPa and PSI.

- Functions of automatic data saving, power failure automatic memory to prevent data loss.

- Multi-level user authority management, login with password.

- Micro-printer and universal USB data interface for convenient data output and transmission(optional).

- DataShieldTM Data Management System enables centralized data management and convenient information system connection (optional)

Test StandardNote1

GB/T 34445, ASTM F1921

Applications

| Basic Applications |

|---|

|

| Extended Applications |

|

Technical SpecificationsNote2

Table 1: Test Parameters Note2

| Parameter/Model | C632M | |

|---|---|---|

| Load Cell Capacity | N | 50 |

| Force Accuracy | FS | 0.5 |

| Force Resolution | N | 0.001 |

| Pressure range | MPa | 0.05i0.7 |

| Pressure resolution | MPa | 0.001 |

| Temperature range | Room temperature 250 | |

| Temperature fluctuation | 0.2 | |

| Test Speed | mm/min | 1500a200012000 |

| Heat Seal Dwell Time | s | 0.1999.9 |

| Delay time | s | 0.01999.99 |

| Extended functions | Software | Optional |

| DataShieldTM Note3 | Optional | |

| Microprinter | Optional | |

Table 2: Technical Specifications

| Sealing Jaw | 1 Set (Double heating) |

| Jaw surface | Metal |

| Jaw size | 100 mm x 10mm |

| Fixture width | 35 mm |

| Sample width | 15 mm or 25 mm or 25.4 mm |

| Fixtures distance | 350 mm |

| Air supply | Dry air (out of supply scope) |

| Air source pressure | 101.5PSI / 0.7 MPa |

| Port size | I6mm PU tubing |

| Dimensions | 32 H x 17 W x 19 D (81cm 43cm 48cm) |

| Power | 120VAC10% 60Hz / 220VAC10% 50Hz (one of two) |

| Net weight | 133Lbsi1460kgi14 |

Configurations

- Standard Configurations

- Mainframe, pneumatic fixtures, sampler, pedal switch, 6 mm tubing

- Optional Parts

- Software, air compressor and DataShieldTM Data ShieldNote3

- Remarks

- The inlet of the air compressor uses 6 mm tubingi14101.5PSI / 0.7 MPai14, the air source is out of supply scope.

Note 1:All the product features are subject to detailed descriptions in the "Technical Parameters.

Note 2: The parameters in the table are measured by professional operators in Labthink Laboratory according to the requirements and conditions of relevant laboratory environmental standards.

Note 3:DataShieldTM Data Management System provides safe and reliable data application support. The system can be shared by multiple Labthink products. Please purchase respectively according to the usage.

Precision and Versatility in Testing

Equipped with a precision lead screw drive and microprocessor-based control, this heat seal strength tester provides exceptional accuracy-within 1%-and a wide test range from 0.01 N to 100 N. Test modes are configurable via software and cater to Peel, Shear, and Tear assessments, making it suitable for diverse packaging materials. The instrument supports single and parallel testing (up to 5 specimens), with adjustable test speed and width to accommodate dynamic industry needs.

User-Friendly Operation and Real-Time Insights

Experience seamless operation through an intuitive large LCD digital display. The tester's automation ensures reliable readings, including peak hold and real-time data, along with automatic calculation and data recall features. Data management becomes easy through multiple export options including USB, printer, and RS232 output. Calibration integrity is preserved with standardized calibration weights, while robust safety features including overload protection and emergency stop deliver confidence in laboratory settings.

FAQ's of Flexible Pouches packaging heat seal strength tester:

Q: How does the Flexible Pouches Packaging Heat Seal Strength Tester ensure accuracy during testing?

A: The tester uses a precision lead screw drive, microprocessor control, and calibration with standard weights, achieving measurement accuracy within 1% of the reading and a fine resolution of 0.01 N.Q: What types of tests can I perform on this equipment?

A: Users can perform Peel, Shear, and Tear tests on flexible pouches or packaging materials, with each mode configurable through software for tailored testing protocols.Q: When should I use peak hold and real-time data functions?

A: Peak hold is ideal for capturing the maximum seal strength during testing, while real-time data helps monitor ongoing force applied to specimens, assisting with process monitoring and quality control.Q: Where is the instrument typically installed and used?

A: This automatic, bench-top device is commonly installed in quality assurance laboratories, R&D departments, and manufacturing units of packaging manufacturers, exporters, and suppliers.Q: What is the procedure for calibrating the tester?

A: Calibration is conducted using standard calibration weights to ensure precise force measurements, maintaining the instrument's compliance with ASTM and ISO standards.Q: How do I export and manage test data?

A: Test results are easily exported through USB, printer, or RS232 interfaces, facilitating efficient data management, record keeping, and analysis for reporting and compliance purposes.Q: What are the benefits of using this heat seal strength tester in quality control?

A: The tester delivers precise, repeatable measurements of heat seal integrity, supports multiple test types, ensures data reliability, and helps meet international quality standards, ultimately enhancing packaging performance and safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Heat Seal and Hot Tack Testers' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese