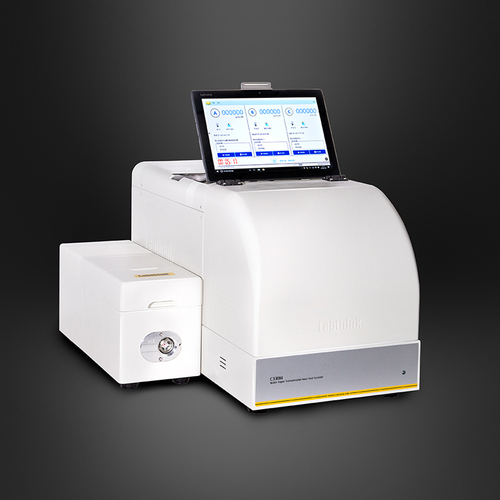

C330H Water Vapor Transmission Rate Test System

Product Details:

- Interface Type RS232, USB

- Response Time <10s

- Equipment Type Water Vapor Transmission Rate Test System

- Power Supply AC 220V / 50Hz

- Operating Voltage AC 220V / 50Hz

- Mounting Type Benchtop

- Automation Grade Fully Automatic

- Click to View more

C330H Water Vapor Transmission Rate Test System Price And Quantity

- 1 Cubic Centimeter

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

C330H Water Vapor Transmission Rate Test System Product Specifications

- Automatic microcomputer control

- <10s

- RS232, USB

- AC 220V / 50Hz

- Water Vapor Transmission Rate Test System

- AC 220V / 50Hz

- 0.01~10 cc/m2day

- Benchtop

- Laboratory/Industrial

- 50 Hz

- Fully Automatic

- 0.01~10,000 g/m224h

- 100 mm x 100 mm

- Three chambers

- Adjustable

- 0.001 g/m224h

- 2%

- 10~90% RH controllable

- 0.6 MPa

- 0.01~10,000 g/m224h

- 3 (simultaneous measurement)

- 15~55C

- 65 kg

- Film, packaging, paper, medical, textile and other materials

- Standard 6 mm pneumatic connection

- LCD touch screen

- 430 mm

- Up to 120 mm

- High precision, rapid test, automatic humidity and temperature control, graphic report export

Product Description

Product Features

Patented Sensor Technology

The instrument uses Labthinks proprietary electrolytic sensor for water vapor analysis, which has excellent precision, repeatability and service life. As a coulometric electrolytic sensor, its signal follows the Faraday principle and has a very high sensitivity.

New Generation Integrated Testing Block

The patented three-cell integrated test block structure using advanced thermodynamics and hydrodynamics analysis greatly improves the temperature, humidity and flow measurement accuracy across the three test cells and supports simultaneous testing of three samples.

Automatic Control of Temperature and Humidity

The internal temperature and humidity of the instrument are automatically adjusted with temperature and humidity sensors, maintaining the stability of the test specimen environment.

Easy-to-use and High-efficiency System

The automatic test mode, combined with the instrument features, eliminates the need for manual adjustments to quickly obtain accurate results, saving training costs and releasing staff from manual monitoring so that they are available for other tasks.

The professional test mode provides flexible and rich instrument control functions to meet individual scientific research needs.

Unique, optional DataShieldTM system, meets the requirements for centralized management of user data. It supports a variety of formats of exported data. Reliable security algorithms are used to prevent data leakage. It supports universal wired and wireless LAN, optional private wireless network and third-party software.

User-oriented Service Concept

Adhering to our user-oriented service concept, Labthink has created a customization system that provides flexible and comprehensive customization services for the accommodation of non-standard specimens and packages.

Test Principle

The test specimen is mounted in the diffusion cell, which is divided into a dry chamber and a controlled-humidity chamber. The dry side of the specimen is swept by a flow of dry nitrogen, and the water vapor permeating through the specimen from the controlled-humidity chamber is carried by dry nitrogen to the electrolytic sensor where proportion electrical signals will be generated. The water vapor transmission rate is obtained by analyzing and calculating the electrical signals. For whole package specimen, the dry nitrogen flows inside the specimen while the outside of specimen is maintained in a high humidity environment.

Test Standards

ISO 15106-3, ASTM F3299, GB/T 21529, YBB 00092003-2015

Advanced Measurement Capability

The C330H offers high accuracy and wide measuring range, capable of detecting water vapor transmission rates from 0.01 to 10,000 g/m224h. It supports both coulometric and gravimetric test methods, providing flexibility for various sample types and research needs.

Effortless Operation and Data Management

Featuring a fully automatic microcomputer control and LCD touch screen, users can conduct tests with minimal effort. Data storage of up to 10,000 records and exportable CSV/PDF reports streamline documentation and analysis, enhancing operational efficiency.

Superior Safety and Convenience

Integrated overheat and leak detection prioritize user safety, while automatic zero-point and span calibration eliminates manual adjustments. Sample preparation is simplified as no pre-conditioning is required, reducing turnaround times in high-throughput environments.

FAQ's of C330H Water Vapor Transmission Rate Test System:

Q: How does the C330H Water Vapor Transmission Rate Test System operate?

A: The C330H utilizes a high precision infrared sensor and automatic microcomputer control to measure water vapor transmission rates from materials. Users select the desired test conditions on the LCD touch screen, and the system provides results within seconds, supporting simultaneous measurement of up to three specimens.Q: What test methods are supported by the C330H system?

A: This system supports both coulometric and gravimetric test methods, enabling users to choose the most appropriate technique for their specific material and research needs. The versatility enhances reliability and application scope.Q: When should automatic calibration be used?

A: Automatic zero-point and span calibration should be performed before each test cycle or as part of routine maintenance. This ensures measurement accuracy and reduces potential for human error, maintaining consistent and trustworthy results.Q: Where is the C330H most effectively used?

A: The C330H is ideally suited for laboratory and industrial settings in fields such as packaging, film, paper, textiles, and medical materials testing. Its benchtop mounting and robust safety features allow safe and efficient operation in controlled environments.Q: What is the process for preparing a sample for testing on the C330H?

A: Sample preparation is straightforward, requiring no pre-conditioning. Specimens should be cut to the appropriate size (100 mm 100 mm) and placed in one of the three available test chambers. The adjustable test stroke accommodates various material thicknesses.Q: How can users benefit from the integrated data export feature?

A: The system's built-in memory stores up to 10,000 records, and results can be easily exported in CSV or PDF format. This enables seamless sharing, archival, or analysis of data, facilitating compliance and reporting requirements in research and industrial applications.Q: What safety features does the C330H provide during operation?

A: Overheat and leak detection safeguard both the instrument and user. Automatic calibration and strict humidity and temperature control further ensure reliable operation, minimizing risks and supporting safe, unattended usage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'OTR/WVTR Test System' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese