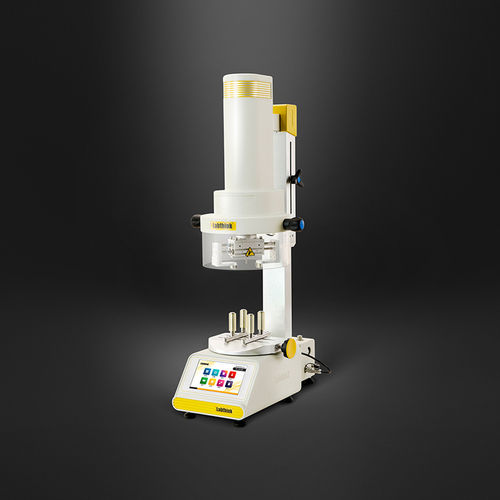

Aluminum Plastic Composite Medicine Package Integrity Flex durability tester

50000 USD ($)/Set

Product Details:

- Display Type LCD digital touch screen

- Interface Type RS232/USB data output

- Application For flex and durability integrity testing of aluminum-plastic composite medicine packages

- Power Supply AC 220V, 50Hz

- Number of Specimens 1-5

- Frequency Single test or cycling mode (programmable)

- Humidity 20% RH - 80% RH (non-condensing)

- Click to View more

X

Aluminum Plastic Composite Medicine Package Integrity Flex durability tester Price And Quantity

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

Aluminum Plastic Composite Medicine Package Integrity Flex durability tester Product Specifications

- LCD digital touch screen

- RS232/USB data output

- For flex and durability integrity testing of aluminum-plastic composite medicine packages

- 10-250 mm/min (adjustable)

- AC 220V, 50Hz

- 1-5

- 500 N (customizable)

- Single test or cycling mode (programmable)

- Material strength and package integrity analysis

- 20% RH - 80% RH (non-condensing)

- 1% of reading

- Max 300 mm

- 220V AC

- 28 kg

- Applicable for soft and rigid blisters

- 0.4-0.6 MPa (compressed air supply)

- 50 ms

- 0-500 N

- 10C to 40C operating range

- Benchtop

- Microcomputer control with touch screen interface

- Durability & Integrity Testing Instrument

- 0-500 N force measurement

- Length 60-300 mm; Width 200 mm

- Semi-automatic

- Overload protection, automatic stop, test data printout, program memory

- 0.01 N

- Standard pneumatic connector, port 8 mm

- 400 mm (with lid open)

- Sample width up to 200 mm

Product Description

Product FeaturesNote1

Multiple Test Modes & High Testing Efficiency

- Five standard test modes including condition A, B, C, D, E and one customized mode F, in which the user can set test cycles freely

- Four stations improve the testing efficiency

- Fast switch between long and short stroke

- Testing environment temperature and humidity are displayed in real time and automatically recorded for data comparison

Renowned Brand Servo Control System with Ultra-long Service Life and Ultra-low Failure Rate

- The instrument is controlled by servo motor, which provides more accurate displacement

- Dual protection for hardware and software as well as auto reset provides a safe operating environment for customers

New Patented Intelligent Touch Operating System

- Industrial grade touch screen, one-button operation, user-friendly interface, remote upgrade and maintenance

- Chinese and English languages can be selected

- Automatic data storage and power failure memory functions

- Historical data can be reviewed and printed easily

- Storage up to 1200 test records

- Multi-level user privilege management, log in with password

- Micro-printer for data exporting and data transfer (optional)

Test StandardNote1

ASTM F392

Applications

| Basic Applications |

|---|

|

|

Technical SpecificationsNote2

| Specification | C681M Flex Durability Tester |

|---|---|

| Flex Frequency | 45 cpm |

| Test Mode | Condition A (2700 cycles), Condition B (900 cycles), Condition C (270 cycles), Condition D (20 cycles), Condition E (20 cycles partial flex), Condition F (020000 cycles) |

| Tensile & Pressing Force | 300 N |

| Torque | 2 Nm |

| Specimen Thickness | 2.5mm (Sample clamps are needed for other thickness specimen) |

| Flex Angle | 440 / 400 |

| Horizontal Stroke | 155 mm / 80 mm |

| Number of Stations | 4 |

| Number of Specimens | 1 4Note3 |

| Specimen Size | 280 mm x 200 mm |

| Instrument Dimension | 760 mm (L) 410mm (W) 650mm (H) |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Net Weight | 85 kg |

Configurations

- Standard Configurations

- Instrument, Adjustable Positioning Ring

- Optional Parts

- Micro-printer, Sample Cutter and Hose Clamp 64(91mm 114mm)

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: Multiple specimens share the tensile & pressing force and the torque.

Advanced Integrity Testing for Pharmaceutical Blister Packs

The LPY-200A tester enables precise flex and durability integrity assessment for aluminum-plastic composite packages. With its non-destructive and destructive testing modes, manufacturers and QC specialists can ensure product safety and packaging reliability before distribution. Data storage capacity, programmable cycling, and intuitive control streamline large-scale testing operations, perfectly adapting to modern pharmaceutical needs.

Engineered for Accuracy and Compliance

Meeting YBB, ASTM, and GB/T packaging standards, the tester delivers consistent and verified results. The system's high-precision linear encoder, automatic/manual calibration, and overload protection safeguard both test integrity and operator safety. Its pneumatic clamping and customizable force range (0-500 N) enable application across soft and rigid blisters, ensuring thorough quality assessments for various packaging types.

FAQ's of Aluminum Plastic Composite Medicine Package Integrity Flex durability tester:

Q: How does the LPY-200A tester ensure the integrity of aluminum-plastic composite medicine packages?

A: The LPY-200A tester uses both destructive and non-destructive testing methods to evaluate the flex durability and integrity of medicine packages. It applies controlled pressure and measures resistance to deformation or failure using a high-precision linear encoder, providing accurate force measurements and immediate feedback on packaging performance.Q: What are the benefits of using pneumatic clamping with adjustable pressure?

A: Pneumatic clamping with adjustable pressure ensures a secure and uniform grip on samples, reducing slippage and test inconsistencies. This feature accommodates various blister types and thicknesses, allowing manufacturers to replicate real-world conditions and obtain precise, repeatable results for both soft and rigid packaging.Q: When should users select non-destructive versus destructive integrity testing?

A: Non-destructive testing is ideal for quality control processes where preserving the sample is critical, such as batch release checks, while destructive testing is chosen for comprehensive package validation or failure analysis. The LPY-200A conveniently allows users to switch between these modes based on their specific needs.Q: Where is the optimal setup location for the LPY-200A tester?

A: The tester should be installed in a well-ventilated area free of corrosive gases, with environmental conditions maintained between 10C to 40C temperature and 20%-80% RH humidity. A stable benchtop with access to AC 220V power and a compressed air supply (0.4-0.6 MPa) is essential for proper functionality.Q: What is the process for calibrating the LPY-200A tester?

A: Calibration can be performed automatically or manually, ensuring the instrument's force measurement accuracy remains within 1%. Calibration weights are provided as accessories, and users can follow the instructions in the user manual to conduct a quick verification before routine operation, maintaining compliance with industry standards.Q: How can test data from the LPY-200A be stored and exported?

A: The device can memorize up to 1000 test results internally. Data output is available through RS232 or USB interfaces for easy transfer, analysis, or printout. This supports efficient documentation, batch tracing, and integration with laboratory data management systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese