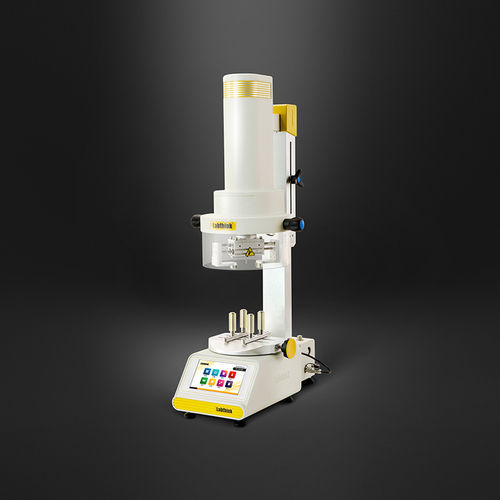

Screw Cap Torque Test of Bottles

50000 USD ($)/Set

Product Details:

- Measuring Range 0.1 to 10 Nm

- Accuracy 1% of full scale

- Resolution 0.01 Nm

- Equipment Type Torque Tester

- Specimen Size 10 mm 180 mm bottle diameter

- Number of Specimens 1 at a time

- Temperature 10C ~ 40C

- Click to View more

X

Screw Cap Torque Test of Bottles Price And Quantity

- 50000 USD ($)/Set

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

Screw Cap Torque Test of Bottles Product Specifications

- 1 at a time

- Manual/Automatic

- 10C ~ 40C

- 0.4~0.7 MPa (if pneumatic)

- 220V/50Hz

- 0.1 to 10 Nm

- 1% of full scale

- 0.01 Nm

- Up to 200 mm

- Up to 2 L bottles

- Torque Tester

- Pharmaceutical, Food & Beverage industry, Laboratory

- 10 mm 180 mm bottle diameter

- Measuring opening/closing torque of bottle caps

- 0.1 10 Nm (Newton Meter)

- 0-300 mm

- Semi-Automatic

- No direct hardness, material: Al-alloy & stainless steel

- Digital LCD

- 5-20 rpm (adjustable)

- AC 220V 10%, 50Hz

- <1 second

- RS232/USB

- 350 mm

- Standard 1/4 inch

- Overload protection, Real-time display, Peak holding function

- 50Hz/60Hz

- Bench-top

- 28 kg

- 85% RH

Product Description

Product FeaturesNote1

Dual Test Modes & Automatic Test with Manipulator

- Dual test modes including application torque test and removal torque test

- Innovative patented manipulator technique supports automatic gripping, opening and fastening, which minimizes the error caused by manual operations and improves the testing accuracy and repeatability

- Gripping force, fastening force and turning speed of the cap can be adjusted freely

- Automatic gripping manipulator with deviation less than 0.01Nm, much better than manual fastening

- Intelligent designs of overload protection, automatic zeroing and error alert for safe test operation

- Manual test or automatic test can be selected

High Testing Accuracy & Low Testing Lower Limit

- Specimens with torque value lower than 0.005Nm is testable. The testing resolution is as high as 0.0001Nm, providing high accuracy and good repeatability.

- The peak value can be maintained automatically, which ensures the recording of the accurate test results

- Automatic judgement of peak value meets the testing requirements for various specimens

- Components and parts are supplied by world well-known manufacturers, which guarantee the stable performance

- Imported pneumatic control system with ultra-long service life and ultra-low failure rate ensures the testing accuracy

New Patented Intelligent Touch Operating System

- Industrial grade touch screen, one-button operation, user-friendly interface, remote upgrade and maintenance

- Chinese and English languages can be selected

- Test curves are displayed in real time. Intelligent data statistics supports quick review of test results.

- Automatic data storage and power failure memory functions

- Historical data can be reviewed and printed easily

- Storage up to 1200 test records

- Test data is expressed in eight international units for reference and comparison

- Multi-level user privilege management, log in with password

- Micro-printer and USB data ports for data exporting and data transfer (optional)

- The instrument conforms to the requirements of GMP (optional)

- Labthinks unique DataShiledTM System for data management and connecting with information system (optional)

Test StandardNote1

ASTM D2063, ASTM D3198, ASTM D3474, BB/T 0025, BB/T 0034, GB/T 17876

Applications

| Basic Applications |

|---|

|

|

| Extended Applications |

|

|

Technical SpecificationsNote2

| Specifications | C612M Digital Torque Tester |

|---|---|

| Load Cell Capacity | 5 Nm (Standard) |

| 20 Nm (Optional) | |

| 40 Nm (Optional) | |

| Accuracy | Indicated Value 0.5%i1410%-100% of Load cell capacityi14 0.05%FS i140%-10% of Load cell capacityi14 |

| Resolution | 0.0001 Nm |

| Body Clamp Range | I5 mm I170 mm |

| Cap Clamp Range | I10 mm I80 mm |

| Bottle Height | 20 mm 400 mm |

| Specimen Clamping and Turning Way | Pneumatic |

| Maximum Auto Removal / Application Torque | 2 Nm (customization available for other specs) |

| Gas Supply | Air (Not in supply scope) |

| Gas Supply Pressure | 0.7 Mpa (101.5psi) |

| Statistical Analysis Allowance | 0 999 |

| Instrument Dimension | 550 mm (L) x 365 mm (W) x 1150 mm (H) |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Net Weight | 39 kg |

Configurations

- Standard Configurations

- Instrument, Gripping Post (4pcs), Gripping Block (1 pair), Calibration Kit (not include weight), 4mm PU Tubing (2m)

- Optional Parts

- Micro-printer, Professional Software, Air Compressor, GMP System, DataShieldTM Note3

- Note

- 1. The gas supply port of the instrument is I4 mm PU Tubing;

2. Customers need to prepare gas supply.

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

Precision Torque Measurement Made Easy

Our Screw Cap Torque Tester delivers highly accurate results, with a measuring range from 0.1 to 10 Nm and an accuracy of 1% of full scale. The digital LCD and peak hold function ensure reliable, real-time data, streamlining your quality control processes for bottles and caps.

Flexible Clamping & Adjustable Testing

Accommodating bottle diameters from 10 to 180 mm, the tester's adjustable clamping and test speed (5-20 rpm) enable quick setup and versatile use. Manual or automatic control modes allow users to optimize for throughput or precision, suitable for a variety of testing applications.

Seamless Data Management & Connectivity

Effortlessly export torque testing results via USB or RS232 interfaces. The integrated memory stores up to 500 test records, simplifying audit trails and quality documentation for compliance. Multilingual support ensures accessibility across global operations.

Robust Construction & Enhanced Safety

Crafted from powder-coated corrosion-resistant materials, the tester is both durable and reliable for demanding environments. An emergency stop button and overload limiter provide crucial safety during operation, protecting both the operator and the instrument.

FAQ's of Screw Cap Torque Test of Bottles:

Q: How does the Screw Cap Torque Tester ensure accurate torque measurement for bottle caps?

A: The tester utilizes a quick-release, adjustable clamping mechanism to securely hold bottles of various diameters (10-180 mm). It measures torque in selectable units (Nm, kgf.cm, lbf.in) with a resolution of 0.01 Nm and 1% full-scale accuracy, ensuring precise quantification of opening and closing forces.Q: What is the process for operating and calibrating the torque tester?

A: Simply clamp the bottle using the adjustable mechanism, select the desired test parameters on the digital LCD interface, and initiate the test in manual or automatic mode. The tester supports both manual and auto-calibration routines for maintaining measurement accuracy over time.Q: Where is the Screw Cap Torque Tester typically used?

A: This equipment is widely employed in pharmaceutical, food & beverage industries, and laboratory environments for quality control purposes, verifying that caps can be opened and closed within specified torque limits to ensure product integrity and safety.Q: What benefits does the data output feature offer?

A: With USB and RS232 connectivity, operators can export test results to software for record-keeping, compliance auditing, and data analysis. Built-in memory stores up to 500 records, facilitating efficient report generation and traceability.Q: When is it recommended to perform calibration on this instrument?

A: Calibration should be conducted during initial setup, after any mechanical adjustments, periodically as part of preventive maintenance, or when measurement discrepancies are observed. Both manual and automatic calibration functions support routine operation.Q: What safety mechanisms does the torque tester provide during use?

A: The instrument features an emergency stop button and a mechanical overload limiter to prevent damage or hazardous situations, ensuring operator safety during high-torque testing scenarios.Q: How does the corrosion-resistant construction benefit long-term usage?

A: The powder-coated body made of aluminum alloy and stainless steel offers superior environmental protection, reducing wear and corrosion over time. This ensures reliable operation and longevity in demanding industrial or laboratory settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese