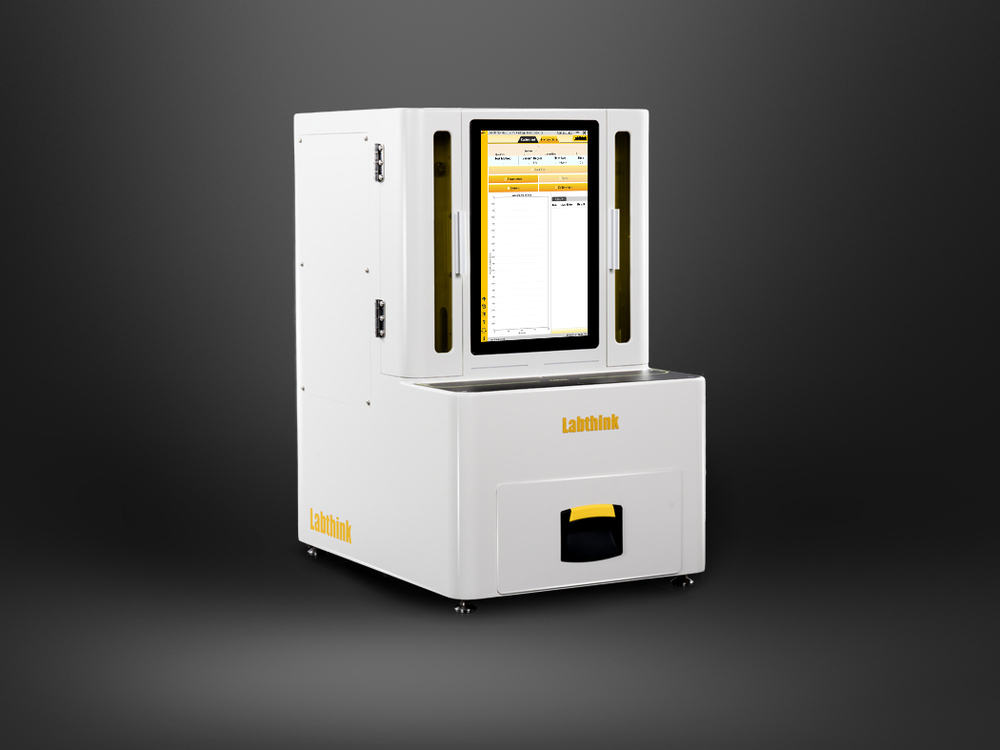

Bubble Leak Test Equipment

2000.00 - 20000.00 USD ($)/Set

Product Details:

- Gas Pressure 0 - 6 bar adjustable

- Port Size 6 mm (Standard) air hose connection

- Humidity Up to 90% RH (non-condensing)

- Response Time Instantaneous

- Measuring Range 0 5 bar

- Automation Grade Manual

- Features Transparent acrylic tank, compact design, easy-to-use controls, quick coupling for air supply, corrosion-resistant body

- Click to View more

X

Bubble Leak Test Equipment Price And Quantity

- 1 Set

- 2000.00 - 20000.00 USD ($)/Set

Bubble Leak Test Equipment Product Specifications

- 0 - 6 bar adjustable

- Up to 250 mm

- Up to 90% RH (non-condensing)

- Instantaneous

- 6 mm (Standard) air hose connection

- Manual, operator controlled

- Digital Controller

- Manual

- 0 5 bar

- One test at a time

- Digital LED display

- Approx. 15 kg

- Transparent acrylic tank, compact design, easy-to-use controls, quick coupling for air supply, corrosion-resistant body

- 300 mm (tank height)

- Benchtop

- Laboratory, quality assurance, production testing

- 230V AC

- Single specimen

- 230V AC, 50 Hz

- 1% of full scale

- 10C to 40C operating

- 50 Hz

- Front panel control

- 0 5 bar

- 0.01 bar

- Variable up to 200 mm

- Up to 250 mm x 250 mm

- Leak testing of flexible packaging and pouches

Bubble Leak Test Equipment Trade Information

- 10 Set Per Week

- 7 Days

Product Description

Technical Specifications- Vacuum Degree 0 ~ -90 KPa

- Accuracy 1% FS

- Vacuum Chamber Effective Sizes 270 mm x 210 mm (H) (standard)

Technical Data

| Vacuum Degree | 0 ~ -90 KPa |

|---|---|

| Accuracy | 1% FS |

| Vacuum Chamber Effective Sizes | 270 mm x 210 mm (H) (standard) |

| 360 mm x 585 mm (H) (optional) | |

| 460 mm x 330 mm (H) (optional) | |

| Note: customization is available for other sizes | |

| Gas Supply Pressure | 0.7 MPa (outside of supply scope) |

| Port Size | 6 mm PU Tubing |

| Instrument Dimension | 300 mm (L) x 380 mm (W) x 450 mm (H) |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Net Weight | 12 kg |

Precise Leak Testing for Flexible Packaging

Built for laboratory and production environments, this bubble leak test equipment enables accurate detection of leaks in packaging using a visual submersion method. Its transparent acrylic tank makes observation easy while the manual, operator-controlled process allows flexibility in testing various specimen types. Complying with ASTM F2096, it ensures reliability and repeatability in quality assurance workflows.

User-Friendly and Safe Operation

Equipped with a front panel digital controller, quick couplings for air supply, and a compact benchtop design, the equipment supports intuitive use. Safety is enhanced by integrated pressure relief valves and overpressure protection, making the testing process secure. The corrosion-resistant build and easy-to-clean drain valve contribute to hassle-free maintenance.

FAQs of Bubble Leak Test Equipment:

Q: How does the bubble leak test equipment work for packaging leak detection?

A: The equipment operates by submerging the test specimen in the transparent acrylic tank filled with water. Air is supplied via an external compressor, and any leaks in the packaging are visually identified through bubble formation, following the ASTM F2096 testing method.Q: What type of specimens and packaging can be tested using this machine?

A: This equipment is designed to test single specimens of flexible packaging and pouches, accommodating sizes up to 250 mm x 250 mm. It is suitable for laboratory, quality assurance, and production settings where packaging integrity is critical.Q: Where is the air supply connected to the device, and is the compressor included?

A: An external compressor must be connected using the standard 6 mm air hose port. The compressor is not included with the equipment; users need to provide their own compatible air source.Q: What safety features are built into the bubble leak tester?

A: Safety mechanisms include a pressure relief valve and overpressure protection to safeguard operators and the equipment during testing. The acrylic tank allows visual inspection, helping to detect any abnormal pressure changes instantly.Q: How is water removed from the tank after testing?

A: A dedicated drain valve is provided for straightforward and efficient water removal, simplifying clean-up and maintenance after each test cycle.Q: What are the benefits of using a transparent acrylic tank for leak testing?

A: The transparent acrylic tank enhances visibility during the bubble detection process, enabling precise observation of leaks and making the testing process more reliable and user-friendly.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Package Leak Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese