vacuum leak test apparatus for vairous packages

Product Details:

- Specimen Size Upto 200 mm package (custom sizes on request)

- Test Range 0 to -600 mm Hg (Vacuum adjustable)

- Gas Pressure Atmospheric (vacuum created during test)

- Power Supply AC mains, 220V, 50Hz

- Temperature Ambient

- Sensor High sensitivity vacuum sensor

- Accuracy 1% of reading

- Click to View more

vacuum leak test apparatus for vairous packages Price And Quantity

- 1 Set

vacuum leak test apparatus for vairous packages Product Specifications

- Up to 85% RH (non-condensing)

- Digital vacuum gauge

- 220V AC, 50 Hz

- 10C to 40C

- 1-5 (Depending on package size)

- Flexible and rigid packaging (polymer, aluminum foil, glass, plastic, etc.)

- Standard 6 mm

- < 2 sec

- Stainless Steel 304

- Ambient

- High sensitivity vacuum sensor

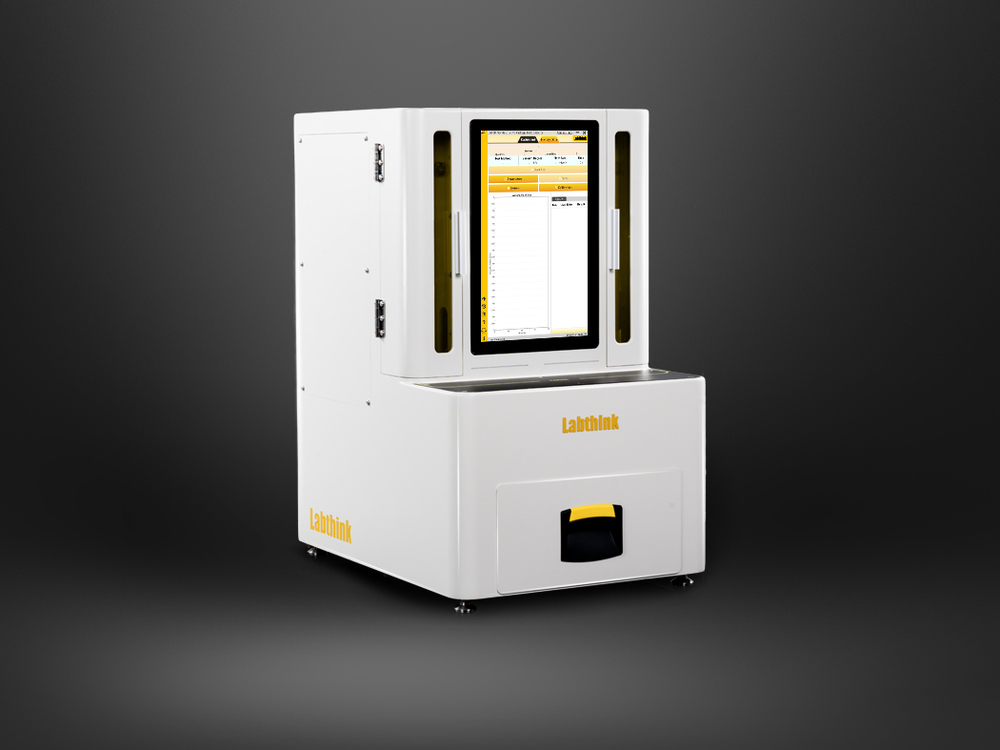

- Bench-top vacuum leak test apparatus

- 200 mm diameter (custom sizes available)

- 1% of reading

- Vacuum leak testing for various packages (pouches, bottles, blisters, strips, vials, ampoules, sachets, etc.)

- Manual / Semi-automatic

- Upto 200 mm package (custom sizes on request)

- Atmospheric (vacuum created during test)

- 0 to -600 mm Hg (Vacuum adjustable)

- AC mains, 220V, 50Hz

- Air (Vacuum)

- Approx. 8 kg

Product Description

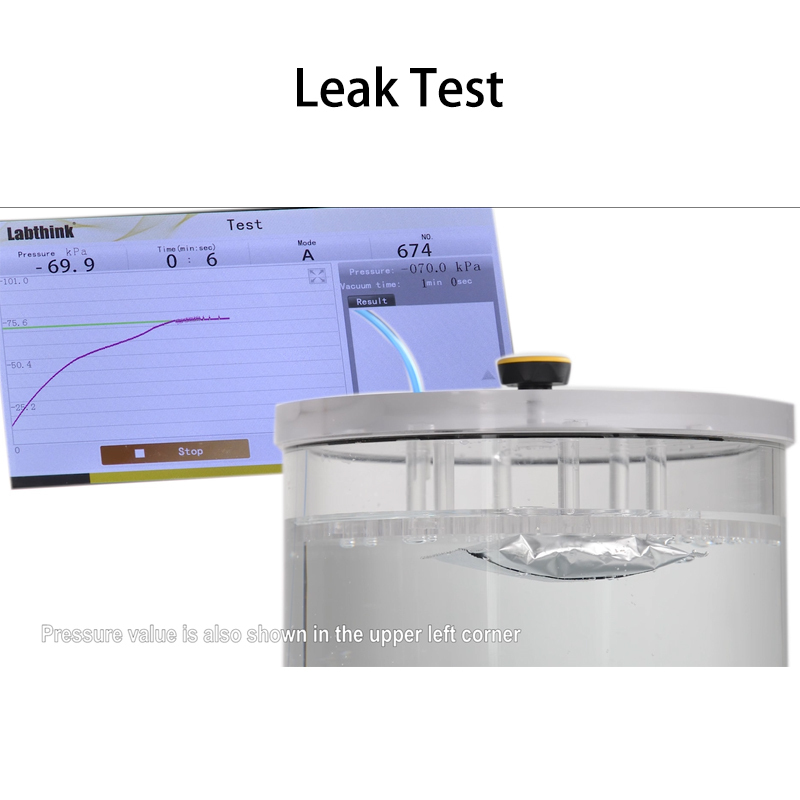

a device for detecting leak using bubble method in accordance with ASTM D3078. It is suitable for flexible packages of different sizes and materials such as large bas, PET or PE bottles, top sealed paper cup & plastic jelly cups, stand up pouches or pillow pouches, flexible tubes, sachets, blister packes, etc.

Features

1. Apply to ASTM D3078

2. Multiple test modes: standard, multi-grade vacuum and methylthionine chloride

3. Real-time display of test curves

4. Built-in vacuum pump

5. Automatic constant pressure compensation

6. Automatic data storage

7. Micro printer and USB ports

Technical Specifications

1. Vacuum Degree: 0 -90 KPa/ 0 -13 psi

2. Accuracy: 0.25% FS

3. Resolution: 0.1 KPa / 0.01 psi

4. Instrument Dimension: 334 mm (L) x 230 mm (W) x 170 mm (H)

5. Net Weight : 6.5kg

Reliable Package Integrity Testing

Our vacuum leak test apparatus enables quality assurance by detecting micro-leaks in a variety of package types. The transparent chamber allows real-time visual inspection, while precise vacuum adjustment and digital monitoring ensure accurate results every time. Suitable for polymer, aluminum foil, glass, or plastic packages, it supports up to five specimens per cycle for enhanced throughput.

User-Friendly Digital Controls

Featuring a digital timer (programmable up to 999 seconds), feather touch keypad or rotary selector, and a digital vacuum gauge, this apparatus provides easy operation without complex training. A maintenance-free vacuum pump ensures quiet operation (< 60 dB), while safety is prioritized with manual or automatic vacuum release options.

Compliance and Versatile Application

Designed to meet international standards such as ASTM F2338 and USP 1207, this apparatus is trusted across pharmaceutical, food, and industrial packaging lines. It efficiently tests packages of up to 200 mm diameter at ambient conditions and up to 85% relative humidity. Custom pedestal sizes are available to suit larger or unique packages.

FAQ's of vacuum leak test apparatus for vairous packages:

Q: How does the vacuum leak test apparatus operate for testing various packages?

A: This apparatus operates by creating a controlled vacuum environment within a transparent chamber. Packages are placed inside, and the air is evacuated using an oil-free vacuum pump. If a leak is present, it is detected by observing bubble formation or pressure changes, verified digitally via the gauge.Q: What types of packages can be tested with this vacuum leak apparatus?

A: It can test a wide range of package formats-including flexible and rigid packages like pouches, bottles, blister packs, strips, vials, ampoules, and sachets-made from materials such as polymers, aluminum foil, glass, and plastic.Q: When is vacuum leak testing necessary in packaging industries?

A: Vacuum leak testing is essential during quality control or validation processes to ensure packaging integrity and safety for products before shipment, particularly in pharmaceutical, food, and industrial sectors.Q: Where can the vacuum leak test apparatus be used?

A: Thanks to its bench-top design, the apparatus is suitable for laboratory, manufacturing, or quality control departments. Its portability and compact size allow easy integration into various workspaces.Q: What is the general process for conducting a vacuum leak test with this apparatus?

A: To conduct a test, place 1-5 specimens (depending on package size) onto the included tray, set the required vacuum and test time using the digital controls, and start the process. Observation is possible through the clear chamber. The vacuum is automatically or manually released after testing, and results are displayed digitally.Q: What are the key benefits of using this specific vacuum leak test apparatus?

A: Its main benefits include maintenance-free operation, precise leak detection, clear observation through a transparent vacuum chamber, easy digital controls, low noise, and compliance with ASTM and USP testing standards. It provides reliable, repeatable results for quality assurance.Q: How is after-sales or technical support provided for this apparatus?

A: Manufacturers and suppliers offer both on-site and remote support to ensure smooth operation and address any technical concerns promptly, allowing users to maintain optimal uptime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Leak and Integrity Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese