Chemicals Products Heat Shrinkage Packaging Characteristics Testing

Product Details:

- Gas Pressure 0.5-0.7 MPa

- Test Range 0-50 mm (shrinkage ratio)

- Display Type Digital LED Display

- Number of Specimens 1-3 samples simultaneously

- Interface Type RS232/USB

- Operating Voltage 220V AC

- Measuring Range 0-100 mm

- Click to View more

Chemicals Products Heat Shrinkage Packaging Characteristics Testing Price And Quantity

- 50000.00 - 100000.00 USD ($)/Set

- 1 Set

- 50000 USD ($)/Set

Chemicals Products Heat Shrinkage Packaging Characteristics Testing Product Specifications

- 45 kg

- 0-100 mm

- 300 mm

- 0.01 mm

- 0-50 mm (shrinkage ratio)

- Microcomputer control, digital display

- 0.5-0.7 MPa

- 220V AC

- 10-500 mm/min (adjustable)

- RS232/USB

- 1-3 samples simultaneously

- Digital LED Display

- Standard sample port

- 100 x 100 mm, customizable

- 50 Hz

- AC 220V, 50Hz

- 0.1 mm

- Automatic operation, real-time data output, multi-sample support

- 300 mm

- Room temperature to 99C

- 200 mm

- Standard laboratory grade

- 40%-80% RH

- <1 second

- Laboratory, industrial packaging QC

- Semi-automatic

- Benchtop

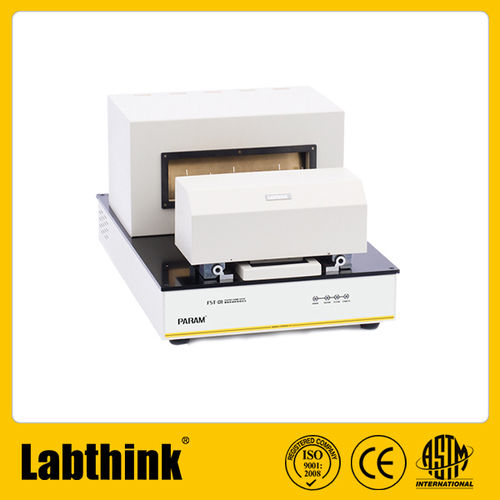

- Heat Shrinkage Packaging Testing Equipment

- Packaging material shrinkage and performance testing

Product Description

Product FeaturesNote1

Innovative Laser Measurement Technology providing Higher Precision and Efficiency

- Advanced laser measurement technology, measures thermal shrinkage ratio of film precisely

- High precision load cell supplied by global renowned manufacturer, provides testing accuracy higher than 0.5%FS and better repeatability of test results

- Multiple test ranges can be selected to meet various testing requirements

- Global renowned brand operating control system guarantees the accuracy of displacement and speed

- Three speeds (up to 2 seconds) for loading specimen can be selected

- Shrinking force, contracting force and shrinkage ratio are displayed in real time

Embedded, Secured and Easy-to-use Computer Controlled System

- Integrated design of instrument and software requires no external computer

- Standard monitor, mouse, keyboard and Window operating interface for simplified operation and data display

- Historical data can be reviewed and printed

- USB ports and net ports for external connection and data transmission

- Intelligent reminder for sensor calibration provides safe data processing environment

- Labthinks unique data security design isolates the test data from computer and prevents data loss caused by computer virus

- Labthinks unique DataShiledTM System for data management and connecting with information system (optional)

Test Principle

The specimen is placed in the test area for displacement and force measurement, it is then heat to the specified temperature for shrinkage test and cooled down. The system automatically records the shrinking force, temperature and shrinkage ratio in real time and provides analytical results.

Test StandardNote1

GBT34848, ISO-14616-1997, DIN 53369-1976

Applications

| Basic Applications |

|---|

|

|

Technical SpecificationsNote2

| Specification | C631H |

|---|---|

| Load Cell Capacity | 5 N (Standard) 10 N, 30 N (Optional) |

| Force Accuracy | Indicated Value 0.5% (10%-100% of Load Cell Capacity) 0.05%FS (0%-10% of Load Cell Capacity) |

| Force Resolution | 0.001 N |

| Displacement Range | 0.1 95 mm |

| Displacement Accuracy | 0.1 mm |

| Shrinkage Ration Range | 0.1%95% |

| Temperature Range | Room Temperature 210C |

| Temperature Variation | 0.2C |

| Temperature Accuracy | 0.5C (Single Point Calibration) |

| Number of Stations | 1 Group (2 pcs) |

| Specimen Size | 110 mm 15 mm (Standard) |

| Instrument Dimension | 480 mm (L) 400 mm (W) 630 mm (H) |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Net Weight | 26 kg |

Configurations

- Standard Configurations

- Instrument, Monitor, Mouse, Keyboard, High-temperature Welding Cloth, T-Plate (10 pcs)

- Optional Parts

- High-temperature Welding Cloth, T-Plate, DataShieldTM Note3

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

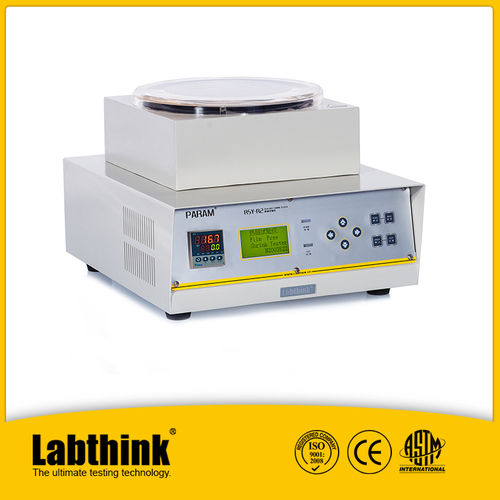

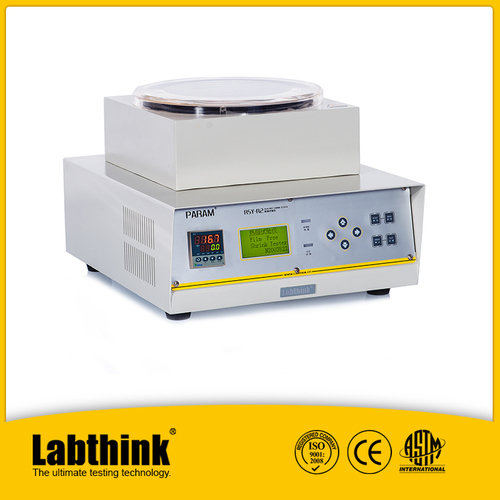

Advanced Shrinkage Testing

Utilize state-of-the-art embedded heating technology and photoelectric detection for accurate, repeatable shrinkage measurements on various packaging materials. The equipment supports multiple film types, including PE, PVC, and POF, ensuring broad material compatibility for comprehensive quality assurance.

Precision and Efficiency

Automatic calibration and fast response time (<1 second) enable quick, precise testing without manual recalibration. Test speeds are adjustable, and you can evaluate up to three specimens at once, optimizing laboratory throughput and improving workflow efficiency.

User-Friendly Operation

The system features intuitive microcomputer controls and a bright digital LED display. Windows-based software simplifies control and reporting, while real-time data output facilitates streamlined analysis. The benchtop design makes it suitable for laboratory or industrial environments.

FAQs of Chemicals Products Heat Shrinkage Packaging Characteristics Testing:

Q: How does the Heat Shrinkage Packaging Testing Equipment detect film shrinkage?

A: The machine uses a sensitive photoelectric sensor to accurately detect and measure film shrinkage during the test. This provides real-time monitoring and high measurement accuracy, supported by digital LED display readouts.Q: What materials are compatible with this testing equipment?

A: The device is suitable for testing the heat shrinkage properties of PE, PVC, and POF films. Its design supports a variety of packaging films commonly used in industrial and laboratory packaging quality control.Q: When is automatic calibration performed on the equipment?

A: Automatic calibration is performed before testing sessions. The systems software automatically configures and calibrates the device, ensuring measurements are precise without manual intervention, and maintaining consistent test results.Q: Where is this equipment typically used?

A: This equipment is ideal for laboratories, industrial quality control departments, and packaging film manufacturers. Its benchtop mounting and compact footprint make it suitable for a variety of workspaces and testing environments.Q: What is the process for conducting a shrinkage test?

A: Begin by placing 1-3 film specimens into the chamber, set test parameters via the digital controls or software, and initiate testing. The embedded heating plates heat the specimens, the photoelectric sensor detects shrinkage, and real-time data is displayed and stored for reporting.Q: How does the machine ensure safety during operation?

A: The equipment is equipped with overcurrent and overheat automatic shutoff features, ensuring safe operation. The active fan cooling system maintains optimal temperatures and protects internal components throughout the testing process.Q: What are the main benefits of using this heat shrinkage tester?

A: Key benefits include high measurement accuracy (0.1 mm), rapid test response, automatic calibration, real-time data output, multi-sample support, and easy integration into laboratory and industrial workflows for consistent packaging quality assessment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Thermal Shrinkage Testers' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese