ASTM E96 Water Vapor Transmission Testing for VCI Paper

Product Details:

- Gas Pressure Manual adjustment, 1 atm max

- Resolution 0.001 g/m24h

- Temperature 15C ~ 50C (adjustable)

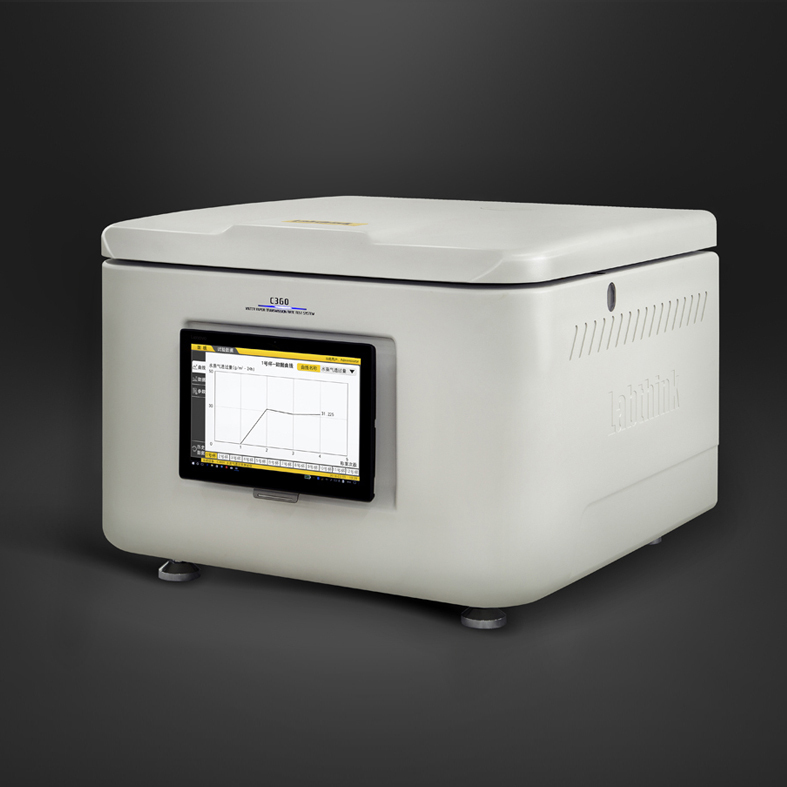

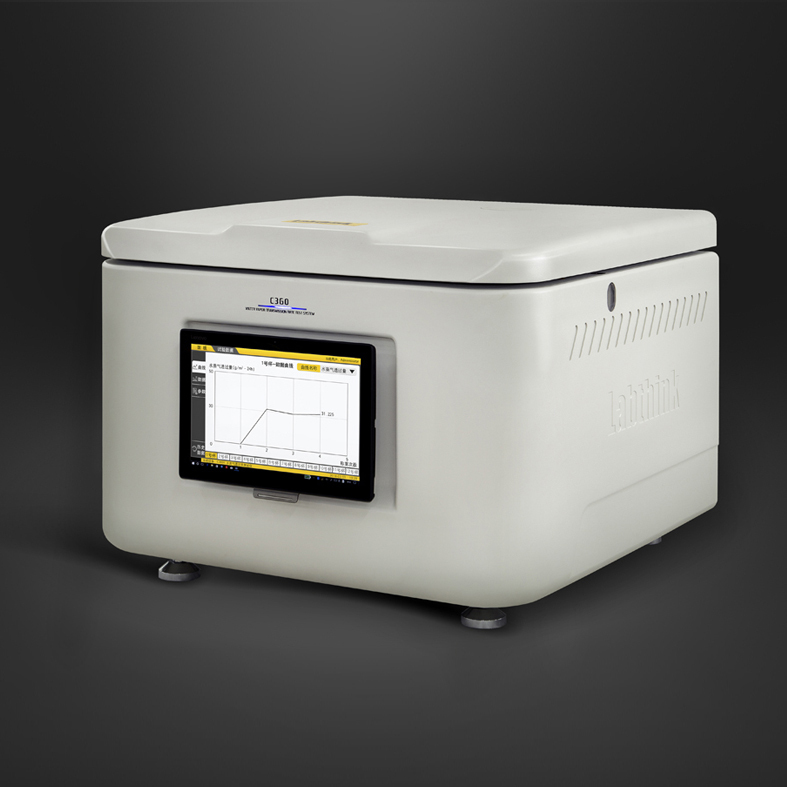

- Equipment Type Water Vapor Transmission Rate (WVTR) Testing Machine

- Power Supply 220V AC, 50Hz

- Operating Voltage 220V AC

- Measuring Range 0.01 ~ 1000 g/m24h

- Click to View more

ASTM E96 Water Vapor Transmission Testing for VCI Paper Price And Quantity

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

- 1 Set

ASTM E96 Water Vapor Transmission Testing for VCI Paper Product Specifications

- Manual adjustment, 1 atm max

- 15C ~ 50C (adjustable)

- Water Vapor Transmission Rate (WVTR) Testing Machine

- 0.001 g/m24h

- Single or multi-specimen analysis

- 220V AC, 50Hz

- 0.01 ~ 1000 g/m24h

- 0.2 ~ 10 mm/min

- 220V AC

- Up to 100% RH (adjustable)

- Microprocessor based automatic control

- Approx. 55 kg

- Automatic data logging, temperature and humidity control

- 0.01 ~ 1000 g/m24h

- 500 mm (equipment height)

- < 5 seconds

- USB and RS232

- Up to 120 mm

- Digital LCD display

- Bench-top

- Water vapor transmission testing of VCI Paper

- 0 ~ 70 mm

- 50Hz

- Fully automatic

- Approx. 80 mm diameter

- Up to 6 at a time

- Laboratory water vapor permeability testing

- 1% of reading

- Standard ASTM diffusion cell ports

Product Description

Product Features

New Generation Test Chamber and Test Dishes

Patented test chamber and test dishes with advanced hydrodynamic and thermodynamic designs ensure the uniform flow rate over the specimen surface, stable temperature and humidity, creating a uniform and stable testing environment. As a result, the test duration is shortened and the test results will be more accurate.

Excellent Testing Abilities of High and Low Barrier Materials

The testing conditions will be regulated precisely in real time, which ensures the high testing accuracy and repeatability of high and low barrier materials.

Automatic Controlling of Temperature, Humidity and Air Velocity

Labthinks proprietary thermostat technology ensures that the test chamber is precisely temperature controlled and remains stable throughout the test.

Air velocity is monitored and regulated in real time.

High-efficiency and mist-free automatic humidity regulator meets the requirements for long-term continuous tests.

It is unnecessary to replace the inner core of the desiccator, which can continuously work for 20,000 hours.

Easy-to-use and High-efficiency System

The automatic test mode, combined with the instrument features, eliminates the need for manual adjustments to quickly obtain accurate results, saving training costs and releasing staff from manual monitoring so that they are available for other tasks.

The professional test mode provides flexible and rich instrument control functions to meet individual scientific research needs.

Unique, optional DataShieldTM system facilitates centralized management of user data. It supports a variety of formats of exported data. Reliable security algorithms are used to prevent data leakage. It supports universal wired and wireless LAN, optional private wireless network and third-party software.

User-oriented Service Concept

Adhering to our user-oriented service concept, Labthink has created a customization system that provides flexible and comprehensive customization services for the accommodation of non-standard specimens and packages.

Test Principle

The test specimen is mounted in the test dish which contains water or desiccant inside. The test dish is placed in the test chamber with stable temperature, humidity and air flow. The water vapor permeates through the specimen and into the dry side. By measuring the weight changes of the test dish periodically, water vapor transmission rate and other parameters can be obtained.

Test Standards

ASTM E96, ASTM D1653, ISO 2528, TAPPI T464, DIN 53122-1, GB/T 1037, GB/T 16928, YBB 00092003-2015

Applications

| Basic Applications |

|---|

|

|

|

|

| Extended Applications |

|

|

Technical Specifications

Table 1: Test Parameters Note1

| Parameter | Model C360H | |

|---|---|---|

| Testing Efficiency | 0.01g/(m2day) 0.5g/(m2day) | >24 hours |

| 0.0006g/(100in2day) 0.0323g/(100in2day) | ||

| 0.5 g/(m2day)5 g/(m2day) | 12 24 hours | |

| 0.0323g/(100in2day) 0.3225g/(100in2day) | ||

| > 5 g/(m2day) | 12 hours | |

| > 0.3225 g/(100in2day) | ||

| Max. Test Range | Water Method | 10000/ni141-12i14g/(m2day) |

| 645/ni141-12i14g/(100in2day) | ||

| Desiccant Method | 1200g/(m2day) per piece | |

| 77g/(100in2day) per piece | ||

| Test Station | 12 | |

| Test Temperature | C | 20 55 0.2 |

| Test Humidity | RH | 10% 90% 1% |

| Additional Functions | DataShieldTM Note2 | Optional |

| Computer System required by GMP | Optional | |

| CFR21 Part11 | Optional | |

Table 2: Technical Specifications

| Specimen Size | I74mm |

|---|---|

| Specimen Thickness | 3mm |

| Test Method | Desiccant Method / Water Method |

| Standard Test Area | 33cm2 |

| Carrier Gas | Compressed Air |

| Drying of Carrier Gas | Long Service-life Desiccator (unnecessary to replace inner core) |

| Humidifying of Carrier Gas | High-efficiency mist-free humidity generator |

| Carrier Gas Pressure | 0.6 MPa |

| Port Size | I6mm PU Tubing |

Note 1: The parameters in the table are measured by professional operator in Labthink laboratory according to relative requirements for laboratory standard conditions.

Note 2: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be purchase as required.

Note 3: The described product features should be in line with Table 1: Test Parameters.

Advanced Testing for VCI Paper and Packaging Films

Equip your laboratory with this fully-automatic WVTR Testing Machine, engineered for assessing water vapor permeability in volatile corrosion inhibitor (VCI) papers and high-performance packaging materials. Its microprocessor-based control system ensures exceptional accuracy and repeatable measurements according to ASTM E96. With digital outputs, adjustable ambient parameters, and precise data analysis software, you can optimize product development and quality assurance processes.

User-Friendly Operation and Data Management

Streamline your workflow with features like automatic data logging, sample cutting templates, and built-in auto calibration. The digital LCD interface, USB/RS232 connectivity, and compatibility with external PC storage facilitate efficient specimen handling and analysis. Operating within 18C-28C and 30%-80% RH, this bench-top unit accommodates routine testing and research alike.

FAQ's of ASTM E96 Water Vapor Transmission Testing for VCI Paper:

Q: How does the WVTR Testing Machine measure water vapor transmission in VCI paper?

A: The WVTR Testing Machine uses ASTM E96 test methods (desiccant and water methods) to determine the water vapor transmission rate through VCI paper. A precision weighing sensor detects mass changes, and automated controls manage test conditions for reliable results.Q: What types of packaging materials are compatible with this equipment?

A: This device is suitable for testing VCI paper, barrier packaging films, and various coating papers. Specimens up to 80 mm in diameter and a width of 120 mm can be accommodated for single or simultaneous multi-specimen analysis.Q: When should I use the desiccant or water method for ASTM E96 testing?

A: Choose the desiccant method for materials expected to resist moisture ingress, and the water method for evaluating permeability under humid conditions. Reference ASTM E96 standards and your product application requirements to select the appropriate method.Q: Where can I store and analyze my test results?

A: Test results can be stored digitally using the built-in data logging feature and exported through USB or RS232 interfaces. Proprietary analysis software allows for detailed examination and reporting on a connected PC or external storage device.Q: What is involved in preparing specimens for testing?

A: Each unit includes a specimen cutting template for precise sample preparation, ensuring consistent sizing and optimal placement in the ASTM standard diffusion cell ports. Up to six samples can be tested simultaneously for comparative analysis.Q: What benefits does automatic calibration provide for this equipment?

A: The built-in auto calibration feature ensures that measurements remain highly accurate (1% of reading) by regularly adjusting the system, reducing manual intervention, and minimizing user error.Q: How does this testing machine contribute to environmental compliance?

A: The equipment is ROHS compliant, ensuring that testing procedures and machine components meet strict regulations on hazardous materials, supporting your company's commitment to sustainable and safe manufacturing practices.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Water Vapor Transmission Rate Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese