Comprehensive Approach of Testing TMM in Hot Drink Cup for Safety

Product Details:

- Test Range 0.1~50 N

- Features Multiple test modes, auto data saving, high compatibility

- Automation Grade Automatic

- Resolution 0.01 mm

- Operating Voltage 220V

- Accuracy 1% F.S.

- Specimen Size Suitable for all standard hot drink cups

- Click to View more

Comprehensive Approach of Testing TMM in Hot Drink Cup for Safety Price And Quantity

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

- 1 Milligram

Comprehensive Approach of Testing TMM in Hot Drink Cup for Safety Product Specifications

- 1% F.S.

- Suitable for all standard hot drink cups

- Material dependent

- Customizable

- 0.01~99.99 mm

- Hot Drink Cup Safety Testing

- 1 sec

- 0.1~50 N

- Multiple test modes, auto data saving, high compatibility

- Automatic

- 0.01 mm

- 76 kg

- Material Safety & Reliability Testing

- 220V

- Comprehensive Testing Machine

- AC 220V 50Hz

- LCD Digital Display

- 50 Hz

- 0.5 MPa (Max)

- RS232

- 1000 mm

- Atmospheric; Room Temp 15~35C

- 10~500 mm/min

- 125 mm

- Microcomputer Control

- Standard 8 mm

- 20%~70% RH

- 350 mm

- Benchtop

- Up to 6 cups

Product Description

Features

Professional

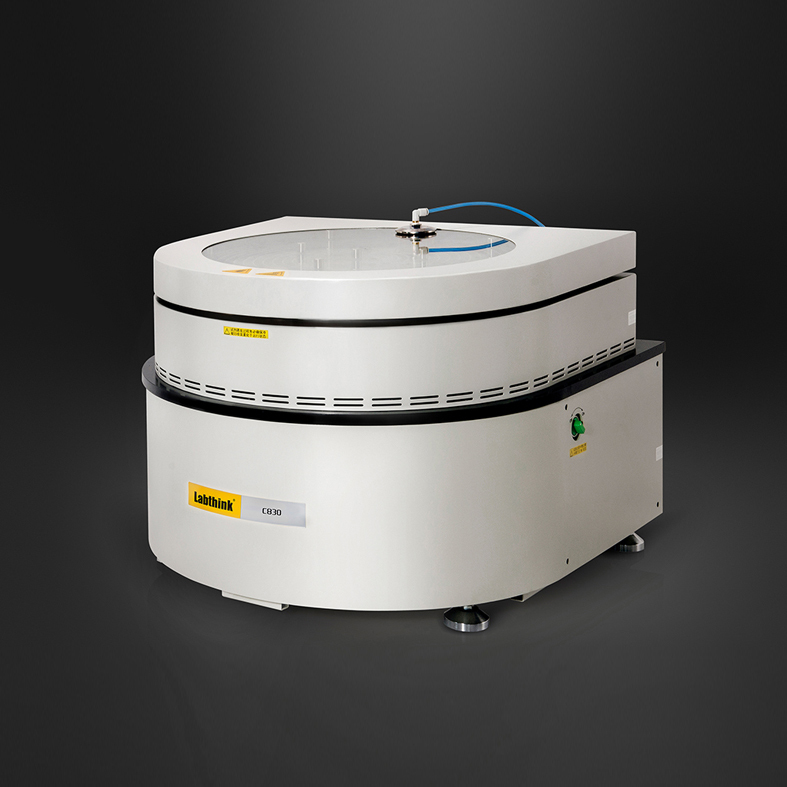

As an innovator and leading manufacturer, Labthink is dedicated to development of testing instrument for determination of migration and non-volatile contents, which is highly-integrated, automatic, precise and harmless.

- Integrated testing process with evaporation, drying and weighing all-in-one instrument, which can be used for determination of migration and non-volatile contents with trichloromethane, acetic acid, ethanol, n-hexane and many other reagents.

- Harmless testing process. The evaporated reagent will be collected and processed through special gas pipes, without requiring additional gas handling systems in laboratory.

- High efficiency reagent recycling function makes it possible to recycle 90% Note1 of n-hexane without introducing extra foreign matters (e.g. bath water).

- The testing process is automatic without human intervention, which can protect the operators from the hazardous gases and guarantee the safety of operators.

- Automatic testing process. With precise automatic weighing system, operating errors can be minimized and constant weight can be obtained effectively.

- Precise testing process. Specially designed constant temperature chamber and weighing system can guarantee the testing accuracy.

High Efficiency

High-efficiency and automatic design minimize the human operation. With advanced technology, the instrument supports simplified test method, testing process and combination of tests.

- Worlds leading fast evaporation technology can reduce the evaporation time by heating the reagent to the status most close to boiling.

- The test chamber can be opened and shut automatically. The airtight test chamber makes the operation safe and simplified.

- With gas balancing technology, the concentration of evaporated reagent can be reduced quickly, which improves the evaporation efficiency and operating safety.

- The testing process is efficient with flexible and professional process parameters as well as multiple test modes including proportional mode, standard mode, differential mode and fast mode, etc.

- The instrument is equipped with 9 working stations, with independent test parameters, process data and test results.

- Labthinks exclusive extended working station mode (optional) supports 9 to 90 stations of multiple testing instruments Note3.

Intelligent

The instrument is embedded with Labthinks latest operating software, which is featured with user-friendly interface, intelligent data processing, strict user management and secure data storage. It also supports Labthink exclusive DataShieldTM Note4 (Optional) which provides the users with safe and reliable management of test data and test reports.

- Test data can be displayed in various forms including curves and data list

- Test data will be saved and encrypted in a unique way so that all the test information will be saved securely and reliably and protected from being tampered

- Various forms of test data can be searched, exported and printed out

Test Principle

Total Migration

The specimen shall be soaked in the solution which is simulator of various food. When the solution is evaporated to dryness, the total migration of non-volatile contents can be measured and calculated.

Non-volatile-matter Content

The specimen shall be soaked in standard reagent. When the reagent and blank liquid bath are evaporated to dryness, the total weight of non-volatile-matter contents can be obtained by comparing with the blank liquid.

Test Standards

ISO 759-1981, GB 31604.8-2016, GB/T 9740-2008, YBB00342002-2015 and YBB00132002-2015, etc.

Applications

| Basic Applications |

|---|

|

|

Technical Specifications

Table 1: Test Parameters Note1

| Parameter \ Model | C830H | |

|---|---|---|

| Test Range | mg | 0.3 80000 |

| Resolution | mg | 0.1 |

| Repeatability | mg | 0.3 |

| Test Temperature | C | Room Temperature 130 |

| Temperature Accuracy | C | 0.5 |

| Additional Functions | Fast Evaporation Mode | Standard |

| Reagent Recycling Function | Standard | |

| Acid, Alcohol & Alkane Test | Standard | |

| Extended Working Station | Optional | |

| DataShieldTM | Optional | |

Table 2: Technical Specifications

| Number of Working Stations | 9 stations with independent weighing systems, test parameters can be different from each other, test data is independent, Customization Available |

|---|---|

| Test Cup Capacity | 200ml, Customization Available |

| Gas Supply | Compressed Air (Power Gas), High-purity Nitrogen (99.999%, Balance Gas) Note: The gas supply is not in supply scope. |

| Gas Supply Pressure | 0.6MPa |

| Port Size | 6mm PU Tubing |

Advanced Simulated Testing for Hot Drink Cups

This equipment applies realistic testing conditions by simulating hot drink filling and pressurized sealing, thoroughly analyzing each cups durability and leak resistance. Precision controls and multiple test modes guarantee accuracy, verifying suitability for actual usage scenarios. The robust stainless steel frame enhances the credibility of test outcomes.

User-Friendly Operation and Robust Data Management

Equipped with a microcomputer system and LCD digital display, the TMM ensures effortless setup and operation. Bilingual language support (Chinese/English) and optional thermal printer enable seamless integration into varied workplaces. Automatic data saving and a large storage capacity empower users with quick data retrieval for audit and quality control.

Strong Safety Protocols and Reliable Performance

Operator safety is paramount with features like emergency stop and over-pressure protection. The machines build supports consistent results with customizable capacity, fast response time (1 sec), and precise measurements. Designed for benchtop mounting, it accommodates diverse laboratory and production environments efficiently.

FAQs of Comprehensive Approach of Testing TMM in Hot Drink Cup for Safety:

Q: How does the Comprehensive Testing Machine ensure the safety of hot drink cups?

A: The machine simulates real hot drink conditions by filling and sealing cups under controlled pressure, performing compression and leakage tests. This process identifies structural weaknesses and ensures cups meet safety and reliability standards.Q: What is the procedure for running a test on this machine?

A: Testing involves placing up to six standard hot drink cups into the holders, setting test parameters via the LCD microcomputer interface, and initiating the process. The equipment automatically simulates hot filling, compresses, and checks for leakage, saving all results digitally.Q: When should calibration be performed on the machine?

A: Calibration should be conducted before the first use, after transport, or periodically as dictated by your quality protocols. The machine offers both manual and automatic calibration to maintain measurement accuracy over time.Q: Where can the Comprehensive Testing Machine be installed?

A: This benchtop machine is designed for laboratory, production, or quality control environments with stable AC 220V 50Hz power, adequate ventilation, atmospheric temperatures of 1535C, and humidity between 20%70% RH.Q: What are the benefits of using this machine for hot drink cup manufacturers and suppliers?

A: Manufacturers and suppliers benefit from assured compliance with safety standards, efficient multi-sample testing, customizable capacity, automated data handling, and enhanced product reliability. Bilingual support and robust construction make it suitable for various international markets.Q: How is data stored and accessed on this machine?

A: The machine can automatically save up to 200 test results, which are accessible via the LCD digital display. For extended record-keeping or analysis, an optional external thermal printer and RS232 interface support data export.Q: What features make this equipment suitable for comprehensive safety and reliability testing?

A: Key features include multiple test modes, high accuracy (1% F.S.), quick response (1 sec), wide measuring and test ranges, safety mechanisms, and compatibility with all standard hot drink cup sizes, ensuring robust and thorough evaluation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Migration & Non-volatile-matter Content' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese