Leather Moisture Permeability Test for Clothing Comfort

Product Details:

- Gas Pressure 0.5 MPa

- Response Time Instantaneous

- Frequency 50 Hz

- Max Height 250 mm

- Operating Voltage 220V

- Temperature Room Temperature to 65C

- Hardness Rugged Housing

- Click to View more

Leather Moisture Permeability Test for Clothing Comfort Price And Quantity

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

Leather Moisture Permeability Test for Clothing Comfort Product Specifications

- 90 mm/min

- AC 220V, 50Hz

- USB Data Output

- 0.01 g/m/24h

- Digital LCD

- Clothing Comfort Measurement in Leather

- 0-5000 g/m/24hr

- 220V

- Room Temperature to 65C

- Rugged Housing

- 100-5000 g/m/24h

- 0.5 MPa

- Instantaneous

- 50 Hz

- 250 mm

- Digital Control

- 40-95% RH

- 75 kg

- 60 mm

- User Friendly, Portable, Stable Performance

- Standard

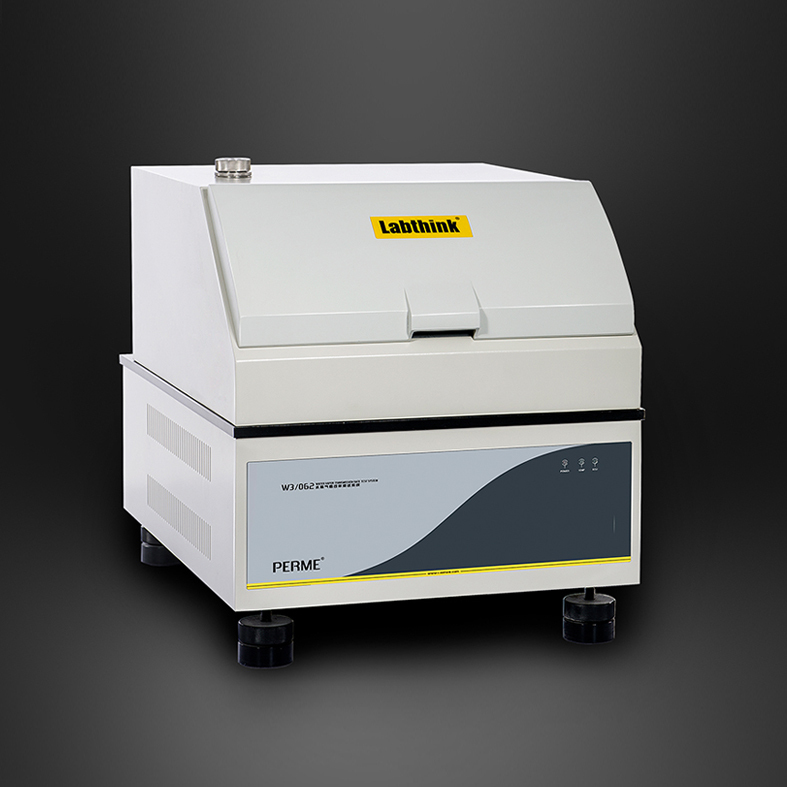

- Leather Moisture Permeability Tester

- Bench-Top

- Semi Automatic

- 85 mm diameter

- High Precision

- 1%

- 45 mm

- Laboratory, Textile Industry

- 3

Product Description

Principle

Under a certain test temperature, a constant humidity difference is generated between two sides of the test specimen. The water vapor permeates through the specimen and into the dry side. By measuring the weight changes of the test dish in different time, water vapor transmission rate and other parameters can be obtained.

Standards

This test instrument conforms to the following standards:

ISO 2528, GB 1037, GB/T 16928, ASTM E96, ASTM D1653, TAPPI T464, DIN 53122-1, JIS Z0208, YBB 00092003

Applications

This instrument is applicable to the determination of water vapor transmission rate of:

| Basic Applications |

|---|

|

|

|

|

| Extended Applications |

|

|

|

|

|

|

|

Technical Specifications

| Specifications | Film Test |

|---|---|

| Test Range | 0.110,000 g/m224h (Water Method) 0.12,500 g/m224h (Desiccant Method) |

| Number of Specimens | 16 with independent test results |

| Accuracy | 0.01 g/m224h |

| Resolution | 0.001 g (Customization Available) |

| Temperature Range | 15C55C (standard) |

| Temperature Accuracy | 0.1C(standard) |

| Humidity Range | Water Method: 90%RH 70%RH Note1 |

| Desiccant Method: 10%RH98%RH Note2 | |

| Humidity Accuracy | 1%RH |

| Air Velocity | 0.52.5 m/s (customization available) |

| Specimen Thickness | 3 mm (customization is available for other thickness) |

| Test Area | 33 cm2 |

| Specimen Size | I74 mm |

| Test Chamber Size | 45 L |

| Gas Supply | Air |

| Gas Supply Pressure | 0.6 MPa |

| Port Size | I6 mm PU tubing |

| Instrument Dimension | 660 mm (L) x 580 mm (W) x 580 mm (H) |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Net Weight | 80 kg |

Note1: Herein the "Humidity means the humidity difference between the two sides of the film specimen. The humidity in the test chamber is 10%30%RH accordingly.

Note2: Herein the "Humidity means the humidity difference between the two sides of the film specimen. The humidity in the test chamber is 10%RH-98%RH when the temperature is 15 to 40 C, 10%RH-90%RH when the temperature is 45 C, 10%RH-80%RH when the temperature is 50 C, 10%RH-70%RH when the temperature is 55 C.

Configurations

- Standard Configurations

- Instrument, Professional Software, Test Dishes, Desiccant Tube, Humidity Generator, Calibration Weight, Communication Cable, Round Sample Cutter and Valve Set

- Optional Parts

- Satellite Base, Reference Film, Air compressor and Desiccant

- Note

- 1. The gas supply port of the instrument is I6 mm PU tubing;

2. Customers will need to prepare for gas supply and distilled water.

Accurate Moisture Permeability Measurement

This advanced tester offers a measurement range of 100-5000 g/m2/24h with 1% accuracy and a high resolution of 0.01 g/m2/24h. The instant response time, coupled with test speed of 90 mm/min, allows for efficient, precise evaluation of leather used in clothing, ensuring consistent comfort and performance data.

User-Friendly and Reliable Operation

Featuring a digital LCD control interface, interchangeable clamp design for multiple specimens, and a programmable timer, the equipment is tailored for efficient operation. Data can be stored in the built-in memory and easily transferred via USB, while overload protection and emergency stop features enhance operational safety.

Versatile and Compliant Design

Manufactured from rugged high-grade stainless steel, the tester is built to withstand demanding laboratory environments. It complies with both DIN and ISO testing standards, supporting a broad ambient range of 10C to 40C, humidity from 40-95% RH, and operational temperatures up to 65C, making it suitable for diverse textile research settings.

FAQ's of Leather Moisture Permeability Test for Clothing Comfort:

Q: How does the Leather Moisture Permeability Tester work in evaluating clothing comfort?

A: The tester measures the rate at which moisture passes through leather specimens using a high-sensitivity sensor and digital control. By simulating real-world conditions, it accurately determines moisture permeability, which is a critical factor for assessing the comfort of leather clothing.Q: What is the process for conducting a moisture permeability test with this equipment?

A: Place up to three leather specimens (85 mm diameter) in the interchangeable clamp holder, set your test cycle using the programmable timer, and start the test. The machine automatically controls the environment, records data on the digital display, and stores up to 1000 results for analysis.Q: When should this tester be used in the textile or leather industry?

A: Use this tester during quality control, research and development, or product evaluation stages whenever precise data on moisture permeability is needed to ensure the end product meets comfort and regulatory standards.Q: Where can the Leather Moisture Permeability Tester be effectively utilized?

A: This bench-top device is ideal for laboratory and industrial settings, especially in textile and leather production facilities, testing labs, and R&D departments concerned with clothing comfort analysis.Q: What software support and data options are included with the tester?

A: The tester features USB connectivity and dedicated analysis software for PC integration. It allows for seamless data export and advanced evaluation, enhancing the usability and traceability of test results.Q: How does the tester ensure test safety and reliability?

A: With built-in overload protection, an emergency stop feature, and compliance with DIN & ISO standards, the tester offers reliable, safe operation. It also includes a calibrated certificate to validate the accuracy of each test.Q: What are the key benefits of using this moisture permeability tester for exporters and manufacturers?

A: This equipment enables manufacturers and exporters to guarantee product consistency, meet international standards, and confidently verify the comfort level of their leather garments, thereby reducing product returns and increasing customer satisfaction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'OTR/WVTR Test System' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese