Hot Tack Testing for Selecting FFS Line Packaging Materials

50000 USD ($)/Set

Product Details:

- Gas Pressure 0.4-0.7 MPa

- Specimen Size 10-75 mm width, 100-300 mm length

- Equipment Type Hot Tack Tester

- Features High Precision Load Cell, Adjustable Heat Sealing Parameters

- Max Height 450 mm

- Mounting Type Bench-top

- Number of Specimens 1-3

- Click to View more

X

Hot Tack Testing for Selecting FFS Line Packaging Materials Price And Quantity

- 50000 USD ($)/Set

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

Hot Tack Testing for Selecting FFS Line Packaging Materials Product Specifications

- 6 mm

- 50 Hz

- 0-50 N

- Semi-Automatic

- 10-75 mm

- High Precision Load Cell, Adjustable Heat Sealing Parameters

- 50-500 mm/min (Adjustable)

- 450 mm

- 300 mm

- 0.4-0.7 MPa

- 10-75 mm width, 100-300 mm length

- Hot Tack Tester

- 1-3

- 220 VAC

- Bench-top

- 50 N

- 0-50 N

- Film and Flexible Packaging Testing

- Digital LCD

- 0.01 N

- Ambient: 5-35C

- FFS Line Packaging Material Selection

- 60 kg

- 220V 10%, 50 Hz

- 0.5% FS

- Microprocessor-Based

- <1 s

- 20-85% RH

- RS232, USB

Product Description

Product FeaturesNote1

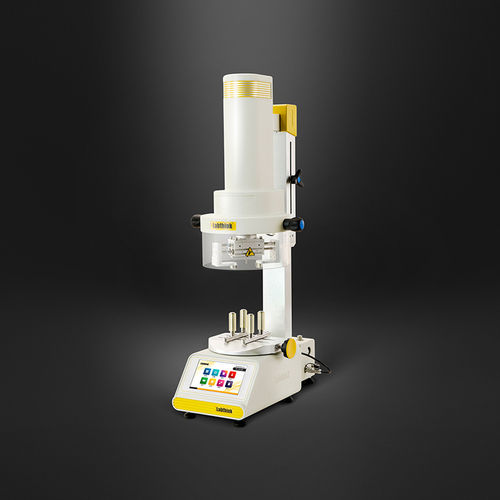

Multiple Test Modes in One Instrument

- Four test modes including hot tack, heat seal, peel and tensile test.

- With Digital P.I.D. temperature control system, the preset temperature can be reached in a short time without fluctuations.

- Four force test ranges and 6 testing speeds are available to meet various testing requirements

- The instrument meets the requirement for testing speed specified in standard GB/T 34445-2017

Excellent Designs & Auto Sampling

- Auto sampling for hot tack test, simplifies the testing operation and minimizes errors, ensures the uniformity of test data

- Pneumatic sample clamping system (optional)

- Automatic zeroing, error alert, overload protection and stroke protection guarantee safe operations

- Instrument can be started manually or by pedal switch. it is convenient for the operator and the anti-scald design ensures safe operations

- Components and parts of the instrument are supplied by world renowned manufacturers and have reliable performance

Computer & Instrument Controlled Operations

- Test operations can be performed on the instrument or by the software

- The instrument can be operated without a computer, easy to operate and view test data

- Data I/O ports for data export

Test StandardNote1

GB/T 34445, ASTM F1921, ASTM F2029, QB/T 2358, YBB 00122003

Applications

| Basic Applications |

|---|

|

|

|

|

| Extended Applications |

|

|

|

|

|

|

Technical SpecificationsNote2

| Specification | C632B Hot Tack Tester |

|---|---|

| Load Cell Capacity | 30 N (Standard) 50 N 100 N 200 N (Optional) |

| Force Accuracy | Indicated Value 1% (10%-100% of load cell capacity) 0.1%FS (0%-10% of load cell capacity) |

| Force Resolution | 0.01 N |

| Test Speed | 150 200 300 500 hot tack 1500mm/min, 2000mm/min |

| Specimen Width | 15 mm, 25 mm or 25.4 mm |

| Stroke | 500 mm |

| Heat Seal Temperature | Room Temperature 250C |

| Temperature Variation | 0.2C |

| Temperature Accuracy | 0.5C (Single Point Calibration) |

| Dwell Time (Heat Seal Test) | 0.1 999.9 s |

| Dwell Time (Hot Tack Test) | 0.1 999.9 s |

| Sealing Pressure | 0.05 Mpa 0.7 MPa |

| Sealing Area | 100 mm x 5 mm |

| Sealing Jaws | Double (one is silicon rubber) |

| Gas Supply | Air (Not in supply scope) |

| Gas Supply Pressure | 0.7 Mpa (101.5psi) |

| Port Size | I4 mm PU Tubing |

| Instrument Dimension | 1120 mm (L) 380 mm (W) 330 mm (H) |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Net Weight | 45 kg |

Configurations

- Standard Configurations

- Instrument, Manual Clamp, Pedal Switch, Sampling Plate, Calibration Support, I4 mm PU Tubing (2m)

- Optional Parts

- Computer, Professional Software, Pneumatic Sample Grips, Air Compressor

- Note

- 1.The gas supply port of this instrument is I4 mm PU Tubing;

2.Customers need to prepare gas supply.

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

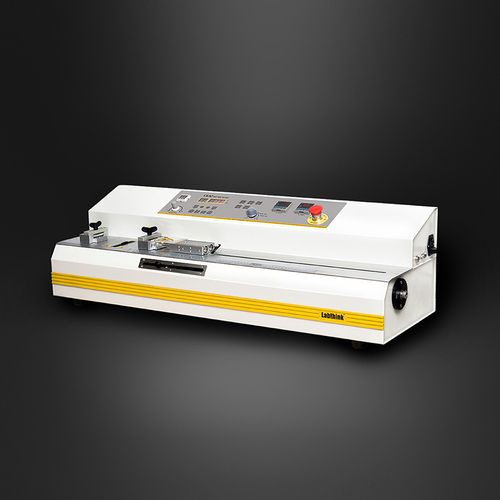

Precision Testing for Packaging Materials

This Hot Tack Tester is specifically designed for evaluating the hot tack strength of film and flexible packaging materials, ensuring optimal sealing performance on FFS lines. With adjustable testing parameters, including seal temperature, time, and pressure, the device enables precise simulations of production environments, supporting reliable material selection and process optimization for manufacturers.

Advanced Features for Enhanced Safety and Usability

Equipped with overload protection, emergency stop, and both manual and automatic calibration options, this tester prioritizes user safety and operational ease. Its stainless steel housing and bench-top mounting provide durability and stability, while the microprocessor-based control mode ensures consistent and accurate measurements for every test cycle.

FAQ's of Hot Tack Testing for Selecting FFS Line Packaging Materials:

Q: How does the Hot Tack Tester assist in selecting FFS line packaging materials?

A: The Hot Tack Tester measures the hot tack strength of films during the sealing process, helping manufacturers determine the most suitable packaging material for FFS lines. By allowing precise control over sealing parameters, it ensures the selected materials consistently meet required performance standards.Q: What is the process for conducting a hot tack test with this equipment?

A: To conduct a test, specimens are prepared (10-75 mm width, 100-300 mm length) and placed in the tester. Seal bar pressure, temperature, seal time, and peel speed are set via the digital LCD interface. After sealing, the tester automatically peels and measures the sealing strength at programmed conditions, with results stored for review.Q: When should hot tack testing be performed during packaging development?

A: Hot tack testing should be performed during the material selection and quality assurance stages of packaging development. It is particularly important when introducing new films, optimizing sealing conditions, or verifying compliance with ASTM F1921 & F2029 standards.Q: Where can the Hot Tack Tester be used effectively?

A: This device is suited for use in quality control laboratories, R&D departments, and production facilities, especially by manufacturers, exporters, and suppliers of flexible packaging films who require ASTM-compliant performance verification.Q: What are the key benefits of using this Hot Tack Tester for film packaging?

A: Key benefits include accurate and repeatable hot tack measurement, adjustable parameters for simulating production conditions, integrated data storage for up to 1000 tests, and compatibility with modern software, which collectively enhance product development and quality assurance.Q: How is user safety ensured while operating the Hot Tack Tester?

A: User safety is maintained through multiple features such as overload protection, an emergency stop button, and robust stainless steel housing. The system also supports automatic and manual calibration to guarantee reliable operation.Q: What makes this Hot Tack Tester suitable for international suppliers and exporters?

A: Its compliance with ASTM standards, microprocessor-based control, multiple interface options (RS232, USB), and compatibility with global voltage and frequency standards make it highly suitable for international use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese