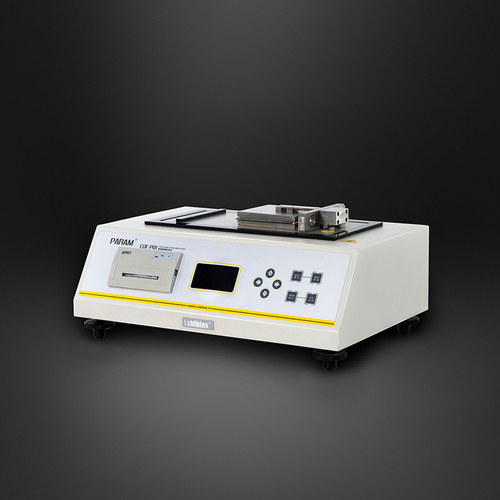

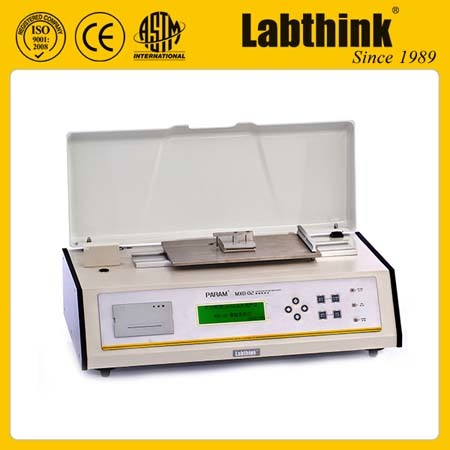

COF-P01 Inclined Surface Coefficient Of Friction Tester

50000 USD ($)/Set

Product Details:

- Humidity 40%85% RH

- Port Size Standard Sample Holder

- Measuring Range 01.0 (COF)

- Power Supply AC 220V/50Hz

- Frequency 50 Hz

- Automation Grade Semi-automatic

- Max Height 150 mm adjustable

- Click to View more

X

COF-P01 Inclined Surface Coefficient Of Friction Tester Price And Quantity

- 50000 USD ($)/Set

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

COF-P01 Inclined Surface Coefficient Of Friction Tester Product Specifications

- Maximum Load 2 kg

- Semi-automatic

- 150 mm adjustable

- Digital LED

- Up to 200 mm

- 40%85% RH

- Standard Sample Holder

- Digital/Manual

- 01.0 (COF)

- AC 220V/50Hz

- 50 Hz

- 0.01

- 1% of reading

- 80 mm x 200 mm

- 045 inclination

- 20 kg

- Variable, 100 mm/min to 500 mm/min

- 220V AC / 50Hz

- 0~300 mm

- RS232 (optional)

- Tabletop

- Determination of the coefficient of friction for sheet materials, films, and paper

- 10C 40C

- Inclined plane mechanism, robust construction, easy calibration, compact design

- Single Specimen Test

- Laboratory, Quality Control

- <1 s

Product Description

Features

- The instrument is professionally applicable to the determination of static coefficients of friction of specimens on the inclined surface

- The functions of freely changeable angular velocity and automatic plane reset support combinations of non-standard test conditions

- The sliding plane and the sled are treated by degaussing and remanence detection which effectively reduce the system errors

- The instrument is controlled by micro-computer with LCD, PVC operation panel and menu interface, which is convenient for customers to test or view the test data

- Equipped with micro-printer and RS232 port for convenient PC connection and data transfer

- Supports LystemTM Lab Data Sharing System for uniform and systematic data management

Standards

This instrument conforms to the following standards:

ASTM D202, ASTM D4918, TAPPI T815

Applications

The instrument is applicable to the determination of static coefficients of friction of:

| Basic Applications |

|---|

|

|

| Extended Applications |

|

|

Technical Specifications

| Specifications | COF-P01 |

|---|---|

| Angle Range | 0 85 |

| Accuracy | 0.01 |

| Angular Velocity | 0.1/s 10.0/s |

| Specifications of Sled | 1300 g (standard) |

| 235 g (optional) | |

| 200 g (optional) | |

| Customization is available for other masses | |

| Ambient Conditions | Temperature: 232C |

| Humidity: 20%RH 70%RH | |

| Instrument Dimension | 440 mm (L) x 305 mm (W) x 200 mm (H) |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Net Weight | 20 kg |

Configurations

- Standard Configurations

- Instrument, Micro Printer and Sled of 1300g

- Optional Parts

- Professional Software, Communication Cable, Sled of 235g, Sled of 200g and Customized Sled

Precision Testing with Motorized Inclined Plate

The COF-P01 utilizes a motorized inclined plate with precise speed control from 100 mm/min to 500 mm/min, allowing laboratories and manufacturers to accurately measure the coefficient of friction. Its robust stainless-steel plate and powder-coated construction ensure longevity and resistance to wear, making it ideal for frequent testing of a wide variety of materials.

User-Friendly Operation and Digital Connectivity

The tester features simple operation with English-language controls, digital LED display, and two calibration modesautomatic or manual. Data output is easily managed via digital readout and USB export, along with optional RS232 interface. Its compact, tabletop mounting makes it convenient for integration into routine quality control processes.

FAQs of COF-P01 Inclined Surface Coefficient Of Friction Tester:

Q: How does the COF-P01 tester determine the coefficient of friction?

A: The COF-P01 operates by gradually increasing the inclination angle of its stainless-steel plate until the test specimen begins to slide. The digital system automatically records the angle and calculates both static and kinetic coefficient of friction values, providing accurate results for films, paper, and sheet materials.Q: What is the process for calibrating the COF-P01 tester?

A: Calibration can be performed automatically via the onboard digital interface or manually following standard procedures. This ensures the accuracy of results. The system guides users through each step, making calibration quick and straightforward for consistent, reliable measurements.Q: When should the emergency stop and overload protections be used?

A: The built-in emergency stop should be engaged if you notice any irregular specimen movement, unexpected operation, or if you need to halt the process immediately for safety. Overload protection is automatically activated if the unit detects forces exceeding its design limits, protecting both the operator and the machine.Q: Where can the COF-P01 be installed for optimal use?

A: The COF-P01 is designed as a compact tabletop unit, ideal for laboratories, research and development centers, and quality control facilities. Its size and ambient noise rating (65 dB) make it suitable for workspaces where other testing or measurement equipment is operated.Q: What materials and specimen sizes are suitable for testing with this device?

A: The tester is engineered for single specimens up to 80 mm x 200 mm in size and supports materials like plastic films, sheets, and papers. The robust sample holder ensures secure placement during the inclination test, and the variable speed accommodates material-specific testing requirements.Q: How do users benefit from the digital output and data export features?

A: Results are displayed instantly on the LED screen with a resolution of 0.01 and can be exported via USB or optional RS232 interface. This facilitates efficient data logging, sharing, and analysis, enhancing traceability and streamlining quality assurance workflows.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Coefficient of Friction Testers' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese