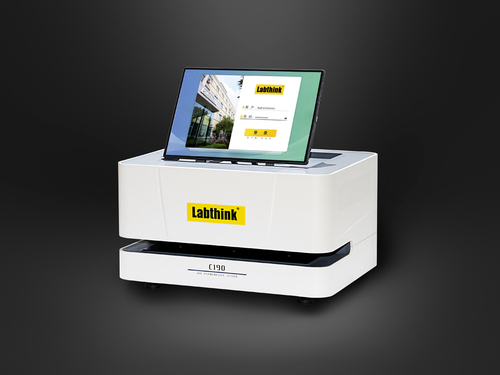

C190H Air Permeability Tester

50000 USD ($)/Set

Product Details:

- Accuracy 2% of Reading

- Response Time < 1 Second

- Specimen Size 300mm 300mm

- Mounting Type Bench Top

- Equipment Type Air Permeability Tester

- Automation Grade Automatic

- Application Textile, Nonwoven, Paper, Leather Air Permeability Testing

- Click to View more

X

C190H Air Permeability Tester Price And Quantity

- 50000.00 - 100000.00 USD ($)/Set

- 50000 USD ($)/Set

- 1 Cubic Centimeter

C190H Air Permeability Tester Product Specifications

- Automatic Data Recording, User-Friendly Interface

- 0.01 mm/s

- USB, RS232

- 50Hz

- Up to 100 mm

- 1 at a Time

- Textile, Nonwoven, Paper, Leather Air Permeability Testing

- 0.1~12000 mm/s

- Automatic

- Air Permeability Tester

- Bench Top

- 300mm 300mm

- < 1 Second

- 2% of Reading

- 300 mm

- 220V

- 10C~35C

- Suitable for standard and nonstandard samples

- 100 cm (Standard Test Area)

- LCD Touch Screen

- 40 cm

- Approx. 40 kg

- Industrial/ Laboratory Testing

- 0.2~0.8 MPa

- AC 220V, 50Hz

- Adjustable, typically 10-30 mm/min

- 0.1~12000 mm/s

- Microcomputer Control

- 20%~70% RH

Product Description

Product Features

Volume Method, Fully-automatic & Highly Precise

- Gas volume passing through the specimen is fully-automatically determined, replacing the traditional manual sliding cylinder gas volume measurement method.

- Fully-automatic high-precision pressure control technology; the pressure accuracy is better than 0.01kPa.

- Test pressure can be set freely by software.

Three-cell Design, Flexible & Efficient

- Three-testing-cell design can accomplish tests for threes specimens in a single test.

- Three-cell independent test and three-cell joint test can be selected freely.

- Fast test mode is provided, and the total test time of three cells is reduced to 1 minute.

Automatic Specimen Clamping, Safe & Labor-saving

- Pneumatic specimen clamping saves time and labor, with consistent clamping force and better sealing.

- Pinch-proof design and safe operation.

Intelligent Control, Convenient and Reliable

- 12 inch tablet of Windows system is installed for more convenient control.

- Embedded unique high-end Labthink industrial computer eliminates system failures caused by computer viruses and ensures operation reliability and data storage security.

- Core sensor and pneumatic control system are from world-renowned manufacturers, with low failure rate and long service life.

- Automatic detection of temperature and humidity of test environment; automatic record of the test conditions.

- The instrument supports multi unit display, such as s/100 mL and um/(Pa.s), which is applicable to the detection requirements of different standards.

- Software has functions such as multi-level authorization management and audit tracking (Optional).

Test Principle

In the test temperature, humidity and atmospheric pressure, the instrument tests the time required for 100mL air passing through the diaphragm with an area of 6.45cm2 under the pressure of 1.21kPa.

Reference Standards

ISO 5636, TAPPI T460, GB/T 36363-2018, GB/T 458-2008, GB/T 23227, GB/T 12655

Applications

| Applications |

|---|

|

|

|

Accurate Air Permeability Testing

The C190H allows precise measurement of air permeability across a wide test range, making it suitable for analysis of various materials such as textiles and paper. Its accuracy of 2% ensures trustworthy results for research and quality control.

User-Friendly and Efficient Operation

Featuring an LCD touch screen and a microcomputer control system, the instrument offers an intuitive user interface. Automated data recording, real-time curves, and data export to PC make your workflow efficient and reliable.

Robust Design and Safety Features

Manufactured with powder coated steel and ABS plastic, the tester is durable for industrial and laboratory use. Equipped with overload protection and an error alarm system, it prioritizes operator safety and instrument longevity.

Versatile Sample and Testing Capabilities

Supporting both standard (300mm 300mm) and nonstandard samples, the C190H enables flexible testing. The adjustable test speed and test width accommodate diverse specimen types for comprehensive analysis.

FAQ's of C190H Air Permeability Tester:

Q: How does the C190H Air Permeability Tester work for different materials?

A: The C190H uses a controlled airflow and precise pressure sensors to measure the rate of air passing through materials like textiles, nonwovens, paper, and leather. It can test various sample sizes and adjusts parameters to match material requirements, delivering accurate real-time results.Q: What benefits does real-time data export and automatic recording provide?

A: Real-time data export and automatic recording reduce manual data handling, minimize errors, and allow direct analysis on a PC. Up to 1000 test records can be stored, supporting traceability and efficient reporting for laboratory or industrial needs.Q: When should I calibrate the tester, and is the process complicated?

A: Calibration can be performed automatically or manually as needed. It is recommended to calibrate periodically, especially before major testing batches or after maintenance, to ensure sustained accuracy. The process is user-friendly via the touch screen interface.Q: Where can this equipment be used and for what types of samples is it suitable?

A: The tester is designed for use in laboratories and industrial settings. It is suitable for both standard and nonstandard specimens, accommodating sample sizes of at least 300mm 300mm, with a standard test area of 100 cm2.Q: How is safety ensured during operation?

A: The C190H includes overload protection and an error alarm system, which monitor operational parameters and automatically halt the process if an unsafe condition is detected, protecting both users and samples.Q: What is the process for performing a test on this machine?

A: Testing involves placing a sample on the bench-top mount, setting test parameters via the touch screen, and initiating the automatic test sequence. The system controls air flow, records data in real time, and presents results on an LCD display or exports them to a PC.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'OTR/WVTR Test System' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese