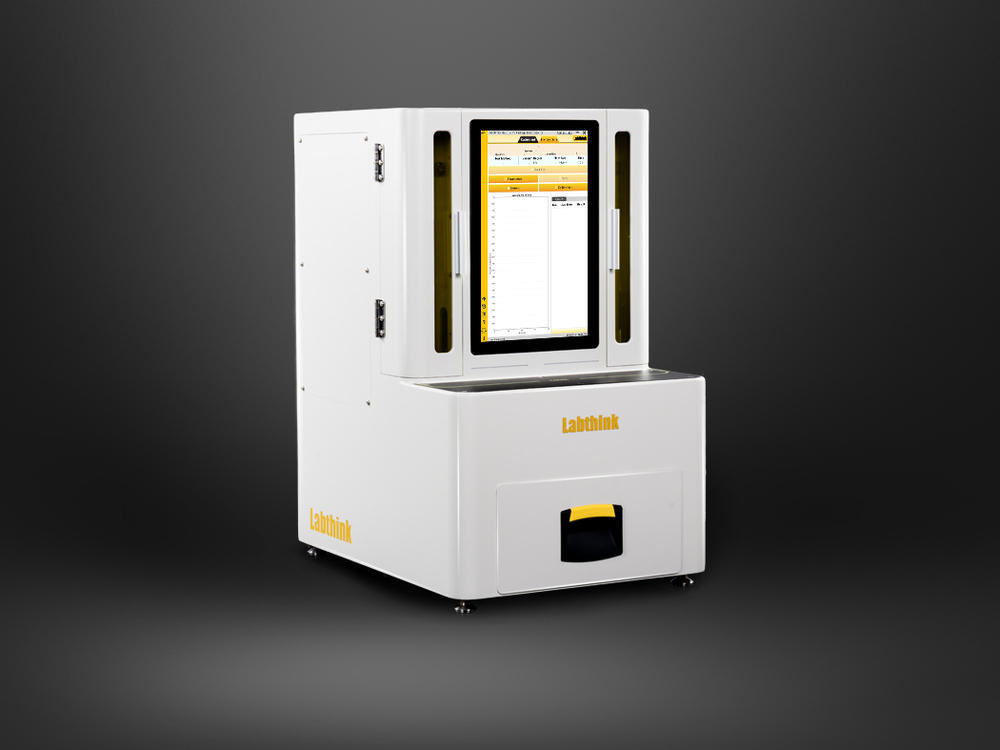

Ensuring Product Integrity with Non-Destructive Packaging Leak Testing

Product Details:

- Automation Grade Automatic

- Test Range 01000 mbar

- Humidity 2080% RH

- Frequency 50/60 Hz

- Mounting Type Benchtop

- Accuracy 1% of reading

- Display Type 7-inch LCD touchscreen

- Click to View more

Ensuring Product Integrity with Non-Destructive Packaging Leak Testing Price And Quantity

- 1 Set

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

Ensuring Product Integrity with Non-Destructive Packaging Leak Testing Product Specifications

- Packaging integrity checking

- 1/4 inch NPT

- USB, RS232

- 220V AC

- 0.1 mbar

- Packaging Leak Testing Machine

- 0.20.6 MPa

- 01000 mbar

- Single/Batch

- Non-Destructive Leak Test for Packaging

- No sample damage, Adjustable pressure, Data logging

- 200 mm

- Up to 4

- Digital Touchscreen

- 45 kg

- 10 tests/minute

- 50/60 Hz

- 01000 mbar

- 2080% RH

- Automatic

- Benchtop

- 0-30 mm adjustable

- 7-inch LCD touchscreen

- 1% of reading

- 540C

- 300 mm

- <2 seconds

- 50300 mm Width

- AC 220V, 50/60Hz

Product Description

Featuresnote1

Batch Testing

- Equipped with fully-automatic gravity fed sample feeder, which is Labthinks latest scientific and technological achievement that can facilitate continuous testing of 20 to 120 samples.

- A & B dual-channel design can test samples of two different specifications simultaneously.

- The target vacuum degree can be set by the operator to meet testing requirements of different samples.

- Dual methods of vacuum decay and pressure decay provide the flexibility to accommodate various types of package samples.

Precise Data

- Advanced pressure detection technology, using world renowned components for data stability which is not affected by ambient environment.

- Advanced microflow automatic flow control technology that can accurately simulate different sizes of leakage holes without manual adjustment.

- Both the differential pressure transducer and flow meter are traceable to NIST.

- The system can achieve a higher test repeatability of 1um.

Intelligent Control

- 15.6" embedded touch tablet computer with Windows OS.

- New longitudinal interface layout, and easy to use graphic user interface.

- Automatic alarm, automatic capture, automatic collection of unqualified samples.

- The pressure curve is displayed in real time, and the test results are counted automatically.

- Leakage rates are calculated automatically.

- The system is equipped with various sensors as intelligent reminders for safer operation and control.

- Universal printer can be connected for test results output.

- The system features embedded with USB and network ports to facilitate the external access and data transmission of the system, which can be upgraded remotely

Security Compliance

- Verified by compensation and calibration methods.

- The leak tester meets GMP requirements for data traceability and meets the needs of the pharmaceutical industry.

- User operation permission is managed at multiple levels, and the permission content can be configured on demand.

- Electronic signature is designed according to the standard requirements of 21 CFR Part11.

Test Principle

The sample is placed in the sample feeder and automatically delivered into the test cell. The leak rate and other results can be calculated and obtained by analyzing pressure changes measured by the sensor.

Reference Standards

ASTM F2338, YY-T 0681.18, and USP<1207>

Applications

| Basic Applications | Vials | Various vial sealing test. |

| Extended Applications | Ampoule | Various ampoule bottle sealing tests. |

| Cartridge Bottles | Various cartridge bottle sealing tests. | |

| Injection bottles | Various injection bottles sealing test. |

Technical Parameters

Table 1: Test Parameters Note2

| ParameterModel | C690H | |

|---|---|---|

| Testing Range | um(Reference aperture size USP1207) | 3i8igreat leakage |

| Detection Lower Limit | um | 3 |

| Resolution | um | 0.1 |

| Repeatability | um | 1 |

| Pressure Range | kPa | -100i0ii14100 |

| Extended Functions | 21 CFR Part11 | Optional |

| GMP computer system requirements | Optional | |

Table 2: Technical Specifications

| Testing Cell | 1 set for A group and 1 set for B group |

| Sample Feeder | 1 set for A group and 1 set for B group |

| Sample Size | I45 mm80mmNote3 |

| Sample Quantity | 20120 pieces |

| Gas Specifications | Compressed Air (Gas source is provided by the user) |

| Gas Source Pressure | 40.6 PSI / 500 kPa |

| Port Size | I6 mm Polyurethane tube |

| Dimensions | 33.4 H x 19.6 W x 28.7 D (85cm 50cm 73cm) |

| Power | 120VAC10% 60Hz / 220VAC10% 50Hzi14select one from the twoi14 |

| Net weight | 209Lbs (95kg) |

Product Configuration

| Standard Configuration | Mainframe, embedded tablet computer, software, flow meter, European vacuum pump, I6 mm polyurethane tube |

|---|---|

| Customization | Test cell and sample feeder of group A, test cell and sample feeder of group B, negative standard reference sample and positive standard reference sample designed according to sample specifications |

| Optional Parts | GMP computer system requirements, 21 CFR Part11, air compressor, IQ/OQ/PQ documents |

Note 1: The described product characteristics are subject to the specific annotation of the "Technical Parameters" table.

Note 2: The parameters in the table are measured in the Labthink laboratory by professional operators according to the requirements and conditions of the relevant laboratory environmental standards.

Note 3: Group C test cell can be customized for samples beyond the "Sample Size", but the lower detection limit and test range will change according to the sample size, and the actual delivery shall prevail.

Versatile Non-Destructive Leak Testing

The equipment employs vacuum decay and differential pressure technology, allowing accurate leak detection while preserving sample integrity. Suitable for a specimen width of 50-300 mm and heights up to 200 mm, users can test a variety of package types-single or batch-ensuring flexible operation for different production requirements.

Intuitive Digital Controls and Reporting

A 7-inch LCD touchscreen provides an intuitive interface for managing tests, adjusting parameters, and reviewing results. Data can be printed or digitally stored, offering traceability and compliance with quality standards. Both automatic and manual calibration options are available to maintain testing precision.

Safety and Compliance Focused Design

Constructed with SS304 stainless steel and equipped with safety interlocks for automatic error shutdown, this machine meets CE and ISO 11607-1 standards. Visual and audible alarms, combined with fast response times and remote diagnostics, support rigorous safety and operational reliability.

FAQ's of Ensuring Product Integrity with Non-Destructive Packaging Leak Testing:

Q: How does the vacuum decay and differential pressure detection method work for non-destructive packaging leak testing?

A: The machine creates a vacuum in its sealed chamber and monitors pressure changes. If a package has a leak, air movement alters the pressure, which is detected precisely by the system. This method assesses seal integrity without causing any damage to the tested packaging.Q: What types and sizes of packages can this machine test?

A: It accommodates up to four specimens at once, with widths ranging from 50 mm to 300 mm and heights up to 200 mm. The adjustable test stroke (0-30 mm) and chamber size make the machine suitable for a wide variety of packaged products.Q: When should calibration be performed on the testing machine?

A: Calibration can be conducted either automatically or manually. Routine checks before testing new product batches or regularly scheduled intervals are recommended to maintain measurement accuracy and compliance with ISO 11607-1 standards.Q: Where can printable test reports and digital data be accessed or stored?

A: Test results can be printed directly for record-keeping or digitally stored via the USB and RS232 interfaces. The 7-inch touchscreen allows users to easily manage, view, and export data for further analysis or documentation purposes.Q: What safety features are built into the Packaging Leak Testing Machine?

A: The equipment includes safety interlocks that automatically shut down testing when an error is detected, preventing accidents or damage. Both visual and audible alarms promptly notify operators of abnormalities, ensuring swift intervention.Q: How does using this machine benefit packaging quality control processes?

A: The system offers non-destructive, high-speed testing-up to 10 tests per minute. It delivers accurate, real-time analysis without damaging samples, facilitating efficient detection of defects, supporting regulatory compliance, and reducing wastage.Q: Can this leak tester be integrated into existing manufacturing setups?

A: Yes, its compact benchtop design, digital touchscreen controls, and standard interface ports (USB, RS232) enable easy integration into current quality assurance workflows. Remote diagnostics and on-site training bolster seamless implementation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Package Leak Tester' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese