Corrugated Carton Box Compression Strength Testers

50000 USD ($)/Set

Product Details:

- Frequency 50 Hz

- Power Supply 220 V, 50 Hz

- Temperature 10C - 40C

- Port Size 50 mm Pneumatic Port

- Operating Voltage 220 V

- Mounting Type Floor standing

- Specimen Size Customizable (standard 600 x 600 mm)

- Click to View more

X

Corrugated Carton Box Compression Strength Testers Price And Quantity

- 50000.00 - 100000.00 USD ($)/Set

- 1 Set

- 50000 USD ($)/Set

Corrugated Carton Box Compression Strength Testers Product Specifications

- Customizable (standard 600 x 600 mm)

- Floor standing

- 0-5000 kg

- 0-1000 mm

- Industrial, Packaging Testing

- 0.01 kg

- Real-time data display, data storage, overload protection

- 20 - 90% RH

- Digital LCD

- 10C - 40C

- 220 V, 50 Hz

- Up to 1200 mm

- 50 Hz

- 220 V

- 50 mm Pneumatic Port

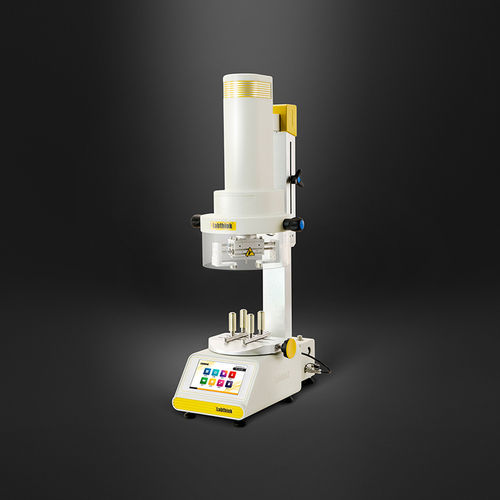

- Compression Strength Tester

- 5000 kg

- <1 second

- 0.5 - 0.7 MPa

- Digital touch screen control

- 10 mm/min to 300 mm/min (adjustable)

- 1200 mm

- 0-5000 kg

- Test plates surface hardness >60 HRC

- Approx. 350 kg

- RS232/USB

- Semi-Automatic

- Testing compression strength of corrugated carton boxes

- 0.5% FS

- 1 per test

Product Description

Product FeaturesNote1

- Compact and integrated design and wide range power supply ?meet the testing requirements of various applications

- Supports crushing force test, stacking test A and stacking test B

- Dynamic digital display of test force, deformation and other test data

- High performance motor and dual precision ball screws support free adjustment of test speed

- Overload protection, maximum stroke protection and error alert for safe test operation

- High end embedded computer-controlled system integrates the instrument with software requires no external computer

- Labthinks unique data security design improves the reliability of data management and test operation

- Windows-like interfaces, keyboard and mouse, which are easy to use

- Four USB ports and dual net ports for data transmission

- The instrument conforms to the requirements of GMP (optional)

- Labthinks unique DataShiledTM System for data management and connecting with information system (optional)

Test StandardNote1

ASTM D642, ASTM D4169, TAPPI T804, ISO 12048, JIS Z0212, GB/T 16491, GB/T 4857.4, QB/T 1048-2004

ApplicationsNote1

| Basic Applications |

|---|

|

|

|

| Extended Applications |

|

|

|

Technical SpecificationsNote2

| Specifications | C611M |

|---|---|

| Load Cell Capacity | 9KN (3 pcs) |

| Accuracy | Indicated Value 1% (10% 100% of load cell capacity) 0.1% FS (0% 10% of load cell capacity) |

| Force Resolution | 1 N |

| Deformation Resolution | 0.1 mm |

| Test Speed | 0 200 mm/min (Any integer within the specified range) |

| Speed Accuracy | Indicated Value 2% |

| Stroke | 450 mm |

| Specimen Height | 0 600 mm |

| Test Space | 0.8 m (L) 0.8 m (W) 0.61 m (H) |

| Instrument Dimension | 0.85 m (L) 1.01 m (W) 1.66 m (H) |

| Power Supply | AC220V10% 50Hz / AC120V10% 60Hz |

| Net Weight | 245 kg |

Configurations

- Standard Configurations

- Instrument, Monitor, Mouse, Keyboard, 150mm Plate (1pcs)

- Optional Parts

- Auxiliary Metering Device, GMP System, DataShieldTM Note3

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

Durable Construction for Demanding Environments

Engineered with a high-grade powder-coated MS frame and platen surfaces exceeding 60 HRC hardness, this tester withstands rigorous industrial use. Its dust-proof and vibration tolerant design ensures reliable performance even in challenging production environments, reducing maintenance and maximizing uptime.

Precision Testing and Compliance

The tester measures compression strengths accurately within a 0-5000 kg range, featuring a 0.5% full-scale accuracy and 0.01 kg resolution. Designed to comply with global standards such as IS 7028 and ASTM D642-01, it is an essential tool for exporters, manufacturers, and suppliers aiming for certified packaging quality.

Advanced Control and Data Management

A digital touch screen simplifies operation and offers flexible control of test parameters like speed and stroke. The built-in printer, USB export, and RS232 interface provide robust data logging and seamless data transfer for comprehensive analysis, facilitating efficient quality documentation and traceability.

FAQ's of Corrugated Carton Box Compression Strength Testers:

Q: How does the Corrugated Carton Box Compression Strength Tester evaluate carton strength?

A: The tester evaluates carton strength by applying controlled compressive force to the box until it buckles or fails. Testers operate within an adjustable speed range (10 mm/min to 300 mm/min) and measure maximum force resisted by the sample, ensuring compliance with standards like IS 7028 and ASTM D642-01.Q: What are the benefits of digital touch screen control in this tester?

A: Digital touch screen control streamlines operation, allowing users to adjust parameters like test speed and stroke with precision. It offers intuitive navigation, real-time test monitoring, and quick access to data storage and export features, significantly enhancing testing efficiency and user experience.Q: When should calibration of the machine be performed, and what are the available methods?

A: Calibration should be carried out periodically or whenever there is a noticeable change in measurement accuracy. This tester supports both manual and automatic calibration methods, ensuring continued testing precision and compliance with industry standards.Q: Where can this compression tester be installed, and what are its mounting and environmental requirements?

A: This is a floor-standing unit best suited for industrial environments such as quality control laboratories, packaging testing centers, or manufacturing plants. Its dust-proof and vibration-tolerant construction allows for reliable usage across diverse workplaces with temperatures from 10C to 40C and humidity between 20-90% RH.Q: What is the testing process for a corrugated carton box using this equipment?

A: Begin by placing the carton specimen on the test platen, configuring test parameters on the digital touch screen, and starting the procedure. The machine applies a compressive force until the carton fails, automatically recording key measurements, which can then be reviewed, printed, or exported for analysis.Q: How can users benefit from the built-in printer and data export features?

A: The built-in printer and USB interface enable immediate reporting and digital record-keeping of test data. Users can effortlessly store results, ensure traceability, and share data for quality audits or production improvements, supporting efficient workflow and regulatory compliance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese