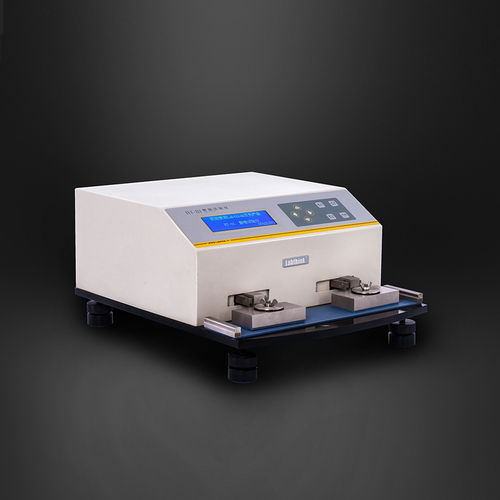

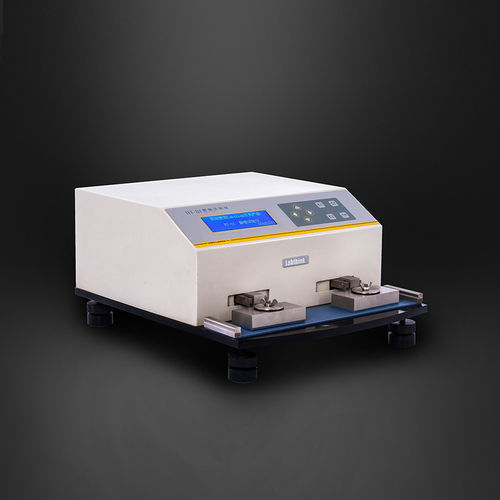

Abrasion Resistance Tester for Printing and Lable

50000 USD ($)/Set

Product Details:

- Accuracy 1 cycle or 1% (whichever is greater)

- Number of Specimens 1 or 2

- Power Supply AC 220V, 50Hz

- Application Printing and label abrasion resistance evaluation

- Automation Grade Semi-Automatic

- Test Range 0999,999 cycles

- Display Type Digital display

- Click to View more

X

Abrasion Resistance Tester for Printing and Lable Price And Quantity

- 1 Set

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

Abrasion Resistance Tester for Printing and Lable Product Specifications

- 1 cycle

- 50 mm

- Abrasion Resistance Tester

- 250 mm

- 65-75 Shore A (specimen pad)

- 20%85% RH

- Approx. 25 kg

- Testing durability of print and label surfaces

- Automatic stop, preset cycle count, easy fixture adjustment

- 220V AC

- 8 mm quick connector

- Digital preset counter

- 050 Newton

- 0.40.6 MPa

- Immediate upon cycle completion

- 60 100 mm

- 1 or 2 samples

- 50 Hz

- 10C40C

- Digital control panel

- 0999,999 cycles

- Digital display

- Tabletop

- Semi-Automatic

- AC 220V, 50Hz

- Printing and label abrasion resistance evaluation

- 60 mm

- 1 cycle or 1% (whichever is greater)

- 1 or 2

- 60 cycles/min

Product Description

Features of Ink Rub Tester

- 4 test modes of dry rub, wet rub, wet transfer, and wet smear and 4 different test speeds to meet different test requirements

- Dual stations with arc movement structure can test equivalent or distinct specimens simultaneously

- Intelligent design of power failure memory and buzzer reminding ensure the safety of test operation

- The instrument is controlled by micro-computer, with PVC operation panel, LCD and menu interface, which is convenient for users to operate or view the test data

Testing Standards

This test instrument conforms to the standard: ASTM D5264, TAPPI T830

Testing Applications

RT-01 Ink Rub Tester is applicable to the determination of abrasion resistance of:

| Basic Applications |

|---|

|

|

Technical Specifications

| Specifications | RT-01 Ink Rub Tester |

|---|---|

| Rub Pressure | 8.9 N(2lb); 17.8N(4lb) |

| Rub Speed | 21, 42, 85, 106 cpm |

| Rub Mode | Arc Reciprocating Movement |

| Rub Times | 0 999999 |

| Number of Specimens | 1 2 |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Instrument Dimension | 485 mm (L) x 390 mm (W) x 230 mm (H) |

| Net Weight | 40 kg |

Configurations

- Standard Configurations

- Instrument, 8.9N (2lb) Test Block, 17.8N (4lb) Test Block and Rubber Cushion

- Optional Parts

- Customized Test Block

Efficient Abrasion Testing for Printing and Labels

Engineered to assess the resilience of printed and label surfaces, this tester delivers precise, repeatable results under both wet and dry conditions. Its digital interface, adjustable fixtures, and user-defined cycle count make it highly suitable for routine quality control and research. The compact, powder-coated steel design assures longevity and stability during ongoing laboratory or production line testing.

User-Friendly Digital Control and Safety Features

Experience seamless operation with the digital preset counter and display, providing immediate cycle completion feedback. The emergency stop switch enhances operator safety, while the automatic stop and digital control facilitate hands-free, reliable evaluations. Quick fixture adjustments further streamline specimen loading and testing process.

Reliable Performance and Construction

Built with a powder-coated steel housing, the tester offers sturdy durability and lasting performance. Its quiet operation (<70 dB(A)) allows usage in workplace environments without causing disruption. The wooden case packaging protects the unit during transportation, ensuring safe delivery.

FAQ's of Abrasion Resistance Tester for Printing and Lable:

Q: How does the Abrasion Resistance Tester evaluate print and label durability?

A: The tester subjects print or label samples to wet and dry abrasion using a standard rubber wheel at an adjustable load. By presetting test cycles on the digital control panel, the machine precisely measures the resistance to surface wear, providing results upon cycle completion.Q: What is the process for conducting an abrasion test with this equipment?

A: To perform a test, the user clamps one or two specimens (each 60 100 mm) into the adjustable fixture, selects wet or dry mode, sets cycles on the digital display, and starts the test. The machine automatically tracks cycles, applying abrasion over a 60 mm stroke, and stops upon reaching the preset count.Q: When should an abrasion resistance test be performed in printing and label manufacturing?

A: Abrasion resistance tests should be conducted during product development, pre-delivery quality checks, or after material or process changes, to ensure the printed or labeled products meet durability standards required for real-world applications.Q: Where can this tester be used?

A: The machine is ideal for quality assurance labs, production facilities, and R&D departments within printing and label production companies. Its compact, tabletop design fits easily into laboratory or workspace environments.Q: How does the adjustable clamping fixture benefit the testing process?

A: The adjustable clamping fixture securely holds various sample sizes, providing flexibility and ensuring accurate, repeatable test results. It is easily adjustable, making sample insertion and removal simple and efficient.Q: What are the safety and ease-of-use features included in the tester?

A: Key features include an emergency stop switch for immediate shutdown, low noise (<70 dB(A)), automatic stop at preset cycle count, digital control panel, and quick fixture adjustments, all enhancing operational safety and user convenience.Q: What advantages does this tester offer to manufacturers and exporters?

A: With accurate measurements (1 cycle or 1%), semi-automatic operation, and robust construction, manufacturers and exporters benefit from reliable testing, improved product quality, and confidence in meeting international standards for abrasion resistance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese