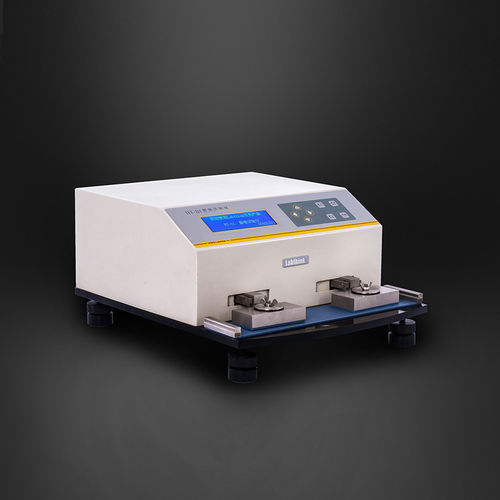

Ink Rub Testing Equipment

50000 USD ($)/Set

Product Details:

- Mounting Type Benchtop

- Interface Type Push Button/Panel

- Response Time Instantaneous

- Automation Grade Semi-Automatic

- Test Range 0 - 9999 cycles

- Display Type Digital LCD

- Resolution 1 cycle

- Click to View more

X

Ink Rub Testing Equipment Price And Quantity

- 1 Set

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

Ink Rub Testing Equipment Product Specifications

- Standard Ink Cartridge Port

- 1 cycle

- 220V

- Digital/Touch Panel

- 1 - 2

- Ink rub resistance testing

- 60 mm

- Benchtop Ink Rub Tester

- AC 220V, 50Hz

- 10C - 40C

- 0-9999 cycles

- Approx. 35 kg

- Ink durable rubbing test, quality control

- 43 cycles/min

- Benchtop

- Instantaneous

- Push Button/Panel

- 100 mm

- 0 - 9999 cycles

- Semi-Automatic

- Approx. 1 test at a time

- Digital LCD

- 1 cycle

- 10% - 90% RH

- 60 mm 220 mm

- 50 Hz

- 220 mm

- Adjustable rub speed, cycle counter, easy specimen mounting

Product Description

Features of Ink Rub Tester

- 4 test modes of dry rub, wet rub, wet transfer, and wet smear and 4 different test speeds to meet different test requirements

- Dual stations with arc movement structure can test equivalent or distinct specimens simultaneously

- Intelligent design of power failure memory and buzzer reminding ensure the safety of test operation

- The instrument is controlled by micro-computer, with PVC operation panel, LCD and menu interface, which is convenient for users to operate or view the test data

Testing Standards

This test instrument conforms to the standard: ASTM D5264, TAPPI T830

Testing Applications

RT-01 Ink Rub Tester is applicable to the determination of abrasion resistance of:

| Basic Applications |

|---|

|

|

Technical Specifications

| Specifications | RT-01 Ink Rub Tester |

|---|---|

| Rub Pressure | 8.9 N(2lb); 17.8N(4lb) |

| Rub Speed | 21, 42, 85, 106 cpm |

| Rub Mode | Arc Reciprocating Movement |

| Rub Times | 0 999999 |

| Number of Specimens | 1 2 |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Instrument Dimension | 485 mm (L) x 390 mm (W) x 230 mm (H) |

| Net Weight | 40 kg |

Configurations

- Standard Configurations

- Instrument, 8.9N (2lb) Test Block, 17.8N (4lb) Test Block and Rubber Cushion

- Optional Parts

- Customized Test Block

Durable and Precise Construction

Crafted from powder-coated mild steel with a gloss enamel finish, the Ink Rub Tester combines robust engineering with aesthetic appeal. Its aluminum sample holder with an anti-slip surface ensures reliable placement during tests, while the noise level remains below 70 dB for a quieter working environment.

Comprehensive Testing Features

Equipped with both felt and rubber pads, the machine adapts seamlessly for different material types. The digital LCD display and programmable timer provide quick setup and consistent results. Adjustable rub speed and a cycle counter further enhance its versatility for accurate ink resistance measurements.

Easy Operations and Safety

A digital touch panel makes the tester user-friendly, and mounting specimens is straightforward. Overload and error alarms ensure safe operation, preventing damage or misuse. The machines benchtop format supports convenient integration into laboratories or production areas.

FAQs of Ink Rub Testing Equipment:

Q: How is the Ink Rub Testing Equipment used for quality control?

A: This equipment is used for ink rub resistance testing by simulating real-world rubbing conditions on printed materials. Its adjustable test speed, programmable timer, and standard 2 lb weight produce consistent and repeatable abrasion, making it ideal for quality control applications in the printing and packaging industries.Q: What materials are compatible with the felt and rubber pads included?

A: Both felt and rubber pads are provided to test a range of printed substrates, such as paper, cardboard, and label stock. The choice of pad depends on the application and material type, ensuring accurate results across diverse testing needs.Q: When should a digital programmable timer be set during testing?

A: The digital programmable timer should be set before beginning each test to define the desired number of cycles (up to 9999) or total test duration. This ensures standardized conditions and reliable measurements for every specimen tested.Q: Where is this Benchtop Ink Rub Tester typically installed?

A: Designed for benchtop mounting, this tester fits efficiently in laboratory settings, quality assurance departments, or on production lines where ink durability assessments are required. Its compact form enables easy integration into existing workflows.Q: What safety features have been incorporated into the machine?

A: To ensure safe operation, the equipment includes overload and error alarms. These features alert users in case of abnormal loading or operational faults, minimizing the risk of damage and enhancing user safety during testing.Q: How does the digital touch panel improve the operation process?

A: The digital touch panel streamlines test configuration and execution. Users can effortlessly select settings such as speed, cycles, and mode, while instant feedback and cycle counting support efficient and accurate test management.Q: What are the key benefits of using this equipment for ink durability testing?

A: Benefits include precise measurement accuracy (1 cycle), rapid response times, and versatility in handling different specimen sizes and materials. The design supports reliable, repeatable results essential for quality control and product validation in printing and manufacturing industries.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

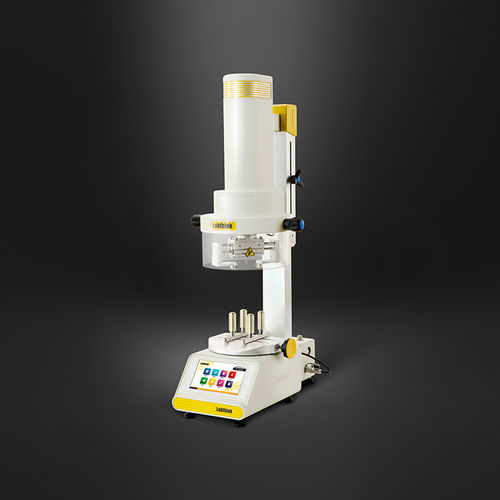

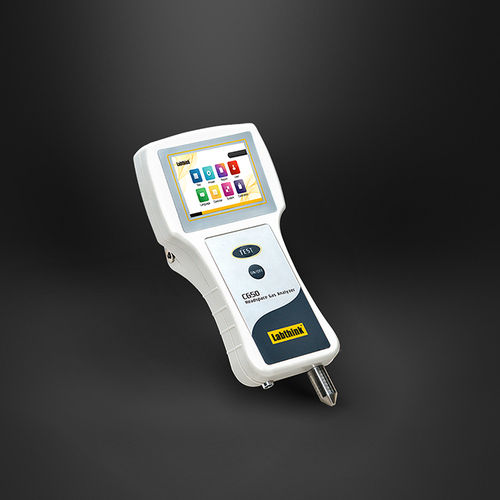

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese