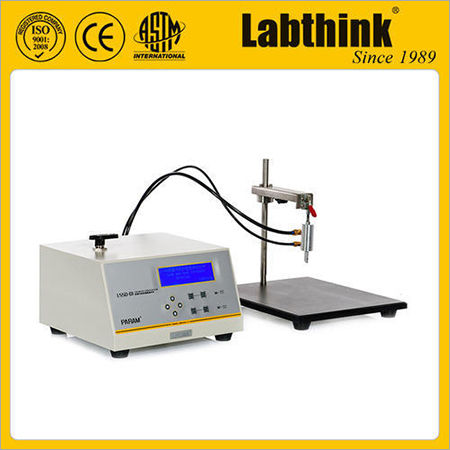

Leak & Seal Strength Tester

2000.00 - 20000.00 USD ($)/Set

Product Details:

- Input Touch keypad input

- Output Digital display

- Product Type Leak & Seal Strength Tester

- Usage Package leak and seal strength testing

- Efficiency High throughput, rapid test cycles

- Standard ASTM F2096, GB/T 15171, ISO 11607-1

- Insulation Material Stainless steel

- Click to View more

X

Leak & Seal Strength Tester Price And Quantity

- 2000.00 - 20000.00 USD ($)/Set

- 1 Set

Leak & Seal Strength Tester Product Specifications

- Silver/Blue

- 15 kg

- Microcomputer controlled

- Leak & Seal Strength Tester

- Package leak and seal strength testing

- 0.1 kPa

- ASTM F2096, GB/T 15171, ISO 11607-1

- Touch keypad input

- Manual/Automatic

- 220V/50Hz, 120W

- Digital display

- 470 mm 380 mm 140 mm

- Bench-top

- High throughput, rapid test cycles

- Stainless steel

- 220V AC

Leak & Seal Strength Tester Trade Information

- 10 Set Per Week

- 7 Days

Product Description

Technical Specifications- Test Range 0~600 KPa; 0~87.0 psi

- 0~1.6 MPa; 0~232.1 psi (optional)

- Resolution 0.1 KPa

- Test Accuracy 0.1% FS

- Gas Injection Head 10 mm (standard)

- 4 mm, 1.6 mm (optional)

Flexible and Accurate Testing

Equipped with an adjustable test range of 0600 kPa and precise 0.01 kPa resolution, this instrument ensures reliable results for a wide variety of package types and materials. Its microcomputer control and digital output streamline process monitoring and enhance data reliability.

Comprehensive Safety Features and Compliance

Safety is prioritized with integrated over-pressure protection and auto-stop functions. The equipment adheres to ASTM F2096, GB/T 15171, and ISO 11607-1 standards, ensuring compliance for global package testing requirements and providing confidence for manufacturers and exporters alike.

Versatility and User-Friendly Operation

Designed to handle materials such as plastic film, laminates, bags, pouches, and foils, the Leak & Seal Strength Tester accommodates both manual and automatic test modes. The touch keypad and easy-to-read LCD digital display make operation efficient for high-throughput environments.

FAQs of Leak & Seal Strength Tester:

Q: How does the Leak & Seal Strength Tester conduct package integrity testing?

A: This tester utilizes adjustable vacuum pressure to evaluate the seal strength and leakage properties of packages. By placing the sample in the test chamber and selecting the desired mode (manual or automatic), the system applies pressure and monitors for seal failure, displaying precise results on the LCD digital interface.Q: What types of packaging materials are compatible with this tester?

A: It is compatible with a broad range of packaging, including plastic films, laminates, bags, pouches, and foils. This versatility allows manufacturers and fabricators to assess various flexible packaging solutions efficiently.Q: When should package leak and seal strength testing be performed?

A: Testing should be carried out during product development, quality control, batch validation, and prior to shipment to ensure that packaging meets regulatory and safety standards, preserving product integrity throughout distribution.Q: Where is the Leak & Seal Strength Tester commonly used?

A: Its bench-top design makes it suitable for laboratories, quality control departments, production facilities, and research and development centers, especially within manufacturing, exporting, and packaging industries.Q: What is the process for data output and analysis from the tester?

A: Test data are displayed in real time on the LCD digital screen and can be exported via the built-in USB interface for further documentation, analysis, or quality reporting, facilitating seamless integration with digital records.Q: How does the tester ensure user safety during operation?

A: The device incorporates over-pressure protection and automatic stop functions to prevent equipment and sample damage. Operators are also given clear alerts via the digital display, enabling safe and controlled test cycles.Q: What benefits does this tester offer for packaging quality assurance?

A: With rapid test cycles, high throughput, accurate results, and international standards compliance, the tester enables manufacturers, suppliers, and exporters to reliably validate package integrity, reduce risk of leakage, and optimize quality across diverse product lines.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Seal Strength Testing Machine' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese