Paper Grocery bags impact resistance test

Product Details:

- Resolution 0.01 N

- Port Size Standard 8 mm

- Application Paper Grocery Bags Quality Testing

- Humidity Relative Humidity 45~75%

- Frequency 50 Hz

- Gas Pressure 0.6~0.8 MPa

- Specimen Size Customizable (e.g., up to 400x600 mm)

- Click to View more

Paper Grocery bags impact resistance test Price And Quantity

- 1 Set

- 50000 USD ($)/Set

Paper Grocery bags impact resistance test Product Specifications

- 1 sec

- 1~10

- 0~500 N

- Semi-Automatic

- Bench Top

- 220V, 50Hz

- 800 mm

- Industrial Grade Steel Components

- 220V

- 1%

- Digital LCD Display

- 15~35C

- 200 mm/min

- Standard 8 mm

- 0.01 N

- Relative Humidity 45~75%

- Approx. 50 kg

- Paper Grocery Bags Quality Testing

- 0.6~0.8 MPa

- 50 Hz

- Standard 500 N

- Material Strength Test

- 0~500 N

- High Precision Sensor, Auto-Stop, Overload Protection

- Customizable (e.g., up to 400x600 mm)

- Digital Control

- up to 400 mm

- Impact Resistance Testing Machine

- 0-300 mm

- RS232/USB

Product Description

Product Features Notes1

- Menu interface, color touch screen operation, convenient and fast to set test parameters.

- Two test modes A and B are provided, and the test status is automatically judged.

- The falling dart adopts the principle of electromagnetic hanging, which can release automatically, effectively avoiding the system error caused by human factors.

- Pneumatic sample clamping, manual and pedal dual start mode, built-in observation lamp unique design; convenient, fast and accurate operation.

- Professional computer software supports the functions of multi unit display of test results, graphic display of test process, output and print function, showing the results clearly and intuitively.

- Micro printer and standard RS232 interface make the tester convenient for the external connection and data transmission between the system and the computer.

Testing Principle

At the beginning of the test, select the test method as the first procedure, estimate an initial mass and m value, and conduct the test. If the first sample is damaged, the weight m shall be used to reduce the falling mass; if the first sample is not broken, the weight m shall be used to increase the falling mass for test in turn. In short, the use of weights to reduce or increase the falling mass depends on whether the previous sample is damaged. After 20 samples are tested, the total number of damaged samples is calculated. If n is equal to 10, the test is completed; if n is less than 10, continue the test after supplementing samples until n is equal to 10; if n is greater than 10, continue testing after supplementing samples until the total number of undamaged samples is equal to 10. Finally, the system automatically calculates the impact results.

Reference Standard Note 1

ISO 7765-1-1988, ASTM D1709, GB/T 9639.1-2008, JIS K7124-1

Test Applications

| Basic Applications |

|---|

|

|

|

| Extended Applications |

|

|

Technical Parameters Note 2

| Items | Parameters |

|---|---|

| Measuring Method | Method A, method B(optional) |

| Test Scope | Method A: 50-2000g Method B: 300-2000g |

| Weight Accuracy | +0.5% |

| Sample Clamping | Pneumatic |

| Air Source Pressure | 0.6 MPa (Prepared by user) |

| Air Connection | 8 mm polyurethane pipe |

| Sample Size | >150 mm x 150 mm |

| Power Supply | 220VAC 50Hz / 120VAC 60Hz |

| Net Weight | 70 kg |

| Dimensions | Amethod:500 mm (L) 450 mm (W) 1320 mm (H) |

| Method B: 500 mm (L) 450 mm (W) 2160 mm (H) |

Product Configuration Note 1

| Standard Configuration | A method configuration, touch screen, micro printer |

|---|---|

| Options | Method B configuration, professional software and communication cable |

| Remarks | The air source interface of the machine is 8 mm polyurethane pipe; the air source is provided by the user |

Note 1: The product functions, reference standards and configuration information are subject to the specific marks in the "technical indicators".

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory according to the requirements and conditions of relevant laboratory environmental standards.

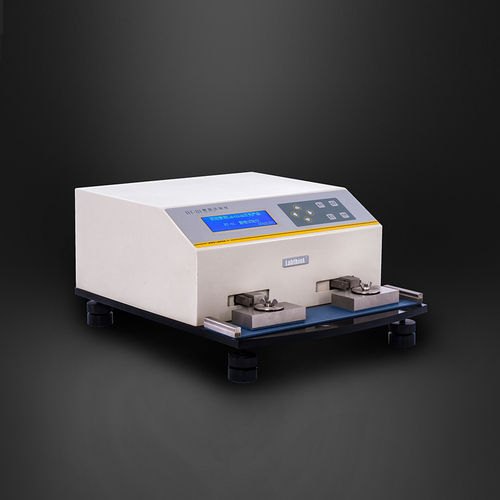

Robust Construction and Safety

Equipped with industrial-grade hardened steel and an enclosed test chamber, this machine assures both equipment longevity and operator safety. Bench-top mounting, overload protection, and auto-stop functions make it secure and straightforward to use, even in repeat or high-throughput environments.

Precise and Customizable Testing

With high-precision sensors, digital LCD display, and customizable specimen sizes, the machine seamlessly adapts to various paper grocery bag types. Digital controls and Windows-compatible software streamline testing and data management, ensuring reliable, traceable results for quality assurance.

FAQs of Paper Grocery bags impact resistance test:

Q: How does the Paper Grocery Bags Impact Resistance Testing Machine operate?

A: The machine uses a hardened steel impact body to apply controlled force to paper grocery bag samples, measuring their resistance to impact. Digital controls and integrated data acquisition record precise results, with adjustable clamps to secure specimens of varying sizes within the enclosed chamber.Q: What is the benefit of using this equipment for paper bag testing?

A: This tester offers high-precision strength evaluations (1% accuracy), enabling manufacturers, exporters, and retailers to ensure that their paper grocery bags meet durability and quality standards, thereby reducing product failures and enhancing customer satisfaction.Q: When and where should impact resistance tests be performed?

A: Tests should be conducted indoors in clean, dust-free settings to maintain accuracy and protect the machine. Preferred operating conditions include temperatures between 1535C and relative humidity within 4575%.Q: What is the process for testing with this machine?

A: After installing the specimen using adjustable clamps, operators set the test parameters via digital controls. The machine performs the impact test at a controlled speed, and the built-in LCD displays the results. Data can be acquired and transferred via RS232/USB interfaces for additional analysis.Q: Which features support operator safety during testing?

A: An enclosed test chamber protects users from accidental contact during operation, while the machines auto-stop and overload protection features further enhance safety throughout the testing process.Q: Can the machine test bags of different sizes or materials?

A: Yes, the sample holder uses adjustable clamps compatible with customizable specimen sizes (up to 400x600 mm), making it suitable for a wide range of paper grocery bag designs and thicknesses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |