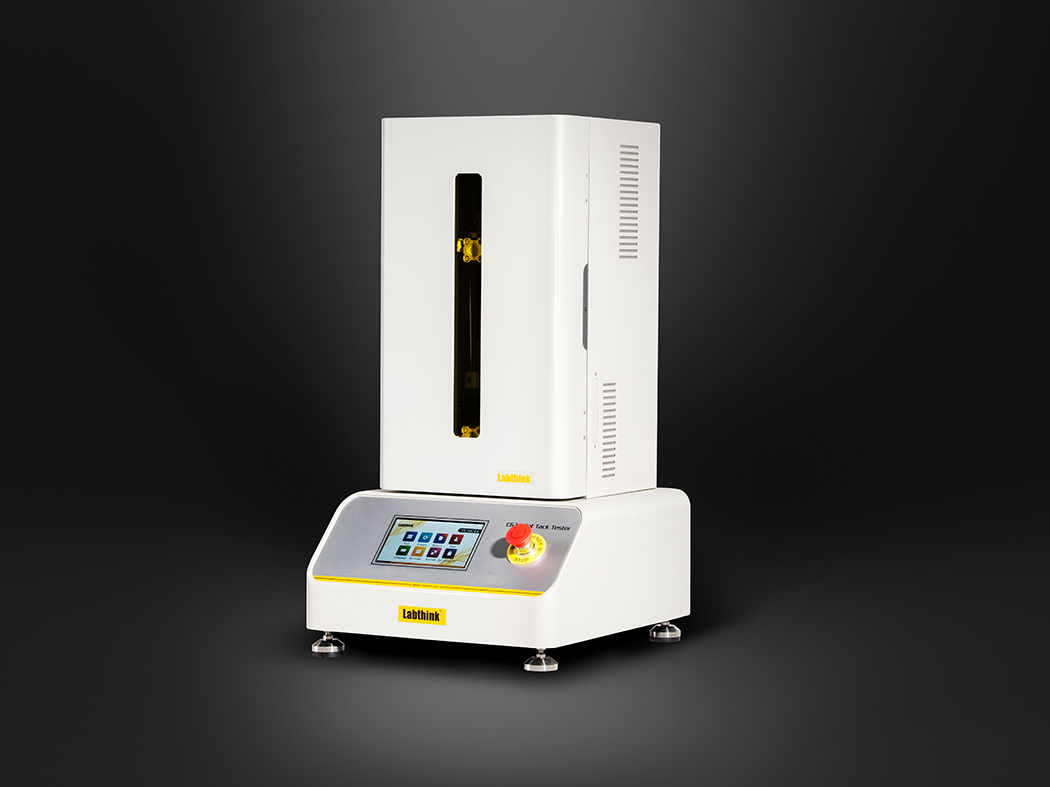

C632M Hot tack Tester

50000 USD ($)/Set

Product Details:

- Application Sealing and packaging strength test of flexible packaging materials

- Frequency 50 Hz

- Resolution 0.01 N

- Power Supply AC 220V 50Hz

- Mounting Type Benchtop

- Measuring Range 0~100 N

- Humidity 40% to 90% RH (non-condensing)

- Click to View more

X

C632M Hot tack Tester Price And Quantity

- 50000 USD ($)/Set

- 1 Set

- 50000.00 - 100000.00 USD ($)/Set

C632M Hot tack Tester Product Specifications

- 0~100 N

- 35 kg

- 40% to 90% RH (non-condensing)

- Hot tack strength measurement for packaging

- Sealing and packaging strength test of flexible packaging materials

- 50 Hz

- 0.01 N

- Benchtop

- AC 220V 50Hz

- Automatic

- 40 mm

- 200 mm/min

- RS232

- Temperature control, high accuracy, digital display

- 1

- 1 ms

- 100 N

- 220V AC, 50Hz

- 0~100 N

- 25 mm

- 0.5 MPa

- 1% of reading

- Digital LCD Display

- Hot Tack Tester

- Room temperature to 250C

- Microprocessor Controlled

- 430 mm

- 6 mm pneumatic

- 100 mm 15 mm

Product Description

Product FeaturesNote1

Constant Pressure & Automated Sample Feeding

- Automatic pressure control technology manages the pressure fluctuation within 0.005MPa

- The test pressure can be set through the program without manual adjustment

- Automatic sample feeding technology to ensure the accuracy of test time

- Upper and lower sealing jaws with metal surfaces can obtain more authentic thermal tack performance

- Digital P.I.D temperature control technology enables the tester to reach the set temperature quickly, effectively avoids temperature fluctuations

Safety Design & Automatic Sample Clamping

- The overall protective cover is designed to prevent hand pinching, scalding and collision, making sure the operation is safer

- Preload fixtures are convenient for sample clamping.

- Pneumatic sample clamping saves time and effort, with consistent clamping force and better sealing efficiency.

- Observation window for clear monitoring of the test process

Intelligent Control & Reliable Performance

- The 7 Inch industrial level Touch panel control for easier operation.

- Sensor static design, reducing force fluctuation

- AC servo system, more stable high-speed operation

- Global sourced core components ensure low failure rate and long service life

- The self-detection function warns of over heat and over limit.

- Support display of multiple units in MPa and PSI.

- Functions of automatic data saving, power failure automatic memory to prevent data loss.

- Multi-level user authority management, login with password.

- Micro-printer and universal USB data interface for convenient data output and transmission(optional).

- DataShieldTM Data Management System enables centralized data management and convenient information system connection (optional)

Test StandardNote1

GB/T 34445, ASTM F1921

Applications

| Basic Applications |

|---|

|

| Extended Applications |

|

Technical SpecificationsNote2

Table 1: Test Parameters Note2

| Parameter/Model | C632M | |

|---|---|---|

| Load Cell Capacity | N | 50 |

| Force Accuracy | FS | 0.5 |

| Force Resolution | N | 0.001 |

| Pressure range | MPa | 0.05i0.7 |

| Pressure resolution | MPa | 0.001 |

| Temperature range | Room temperature 250 | |

| Temperature fluctuation | 0.2 | |

| Test Speed | mm/min | 1500a200012000 |

| Heat Seal Dwell Time | s | 0.1999.9 |

| Delay time | s | 0.01999.99 |

| Extended functions | Software | Optional |

| DataShieldTM Note3 | Optional | |

| Microprinter | Optional | |

Table 2: Technical Specifications

| Sealing Jaw | 1 Set (Double heating) |

| Jaw surface | Metal |

| Jaw size | 100 mm x 10mm |

| Fixture width | 35 mm |

| Sample width | 15 mm or 25 mm or 25.4 mm |

| Fixtures distance | 350 mm |

| Air supply | Dry air (out of supply scope) |

| Air source pressure | 101.5PSI / 0.7 MPa |

| Port size | I6mm PU tubing |

| Dimensions | 32 H x 17 W x 19 D (81cm 43cm 48cm) |

| Power | 120VAC10% 60Hz / 220VAC10% 50Hz (one of two) |

| Net weight | 133Lbsi1460kgi14 |

Configurations

- Standard Configurations

- Mainframe, pneumatic fixtures, sampler, pedal switch, 6 mm tubing

- Optional Parts

- Software, air compressor and DataShieldTM Data ShieldNote3

- Remarks

- The inlet of the air compressor uses 6 mm tubingi14101.5PSI / 0.7 MPai14, the air source is out of supply scope.

Note 1:All the product features are subject to detailed descriptions in the "Technical Parameters.

Note 2: The parameters in the table are measured by professional operators in Labthink Laboratory according to the requirements and conditions of relevant laboratory environmental standards.

Note 3:DataShieldTM Data Management System provides safe and reliable data application support. The system can be shared by multiple Labthink products. Please purchase respectively according to the usage.

Precise Hot Tack Testing for Packaging Materials

The C632M Hot Tack Tester offers superior precision and repeatability in determining the hot tack and seal strength of flexible packaging films. Featuring high-resolution temperature control and rapid response time, it delivers reliable data that ensure packaging integrity and performance. The benchtop setup, easy operation, and compliance with international standards make it suitable for quality assurance laboratories and production environments.

User-Friendly Controls and Digital Display

Equipped with microprocessor-based controls and a clear digital LCD display, the C632M streamlines testing and data acquisition. Adjustable settings for sealing pressure, temperature, and timing enable customization to a wide range of materials. Users benefit from the machine's intuitive interface, automated operation, and seamless data export through USB or RS232 connections.

Versatile and Accurate Measurements

Engineered for flexibility, the C632M accommodates a variety of specimen sizes and test conditions. Its 0~100 N measuring range, 0.01 N resolution, and 1% accuracy ensure that every test yields dependable results. Whether in research and development or regular quality inspections, this tester offers consistent, standard-compliant performance.

FAQ's of C632M Hot tack Tester:

Q: How does the C632M Hot Tack Tester function during a sealing strength test?

A: The C632M Hot Tack Tester performs sealing strength tests by clamping the flexible packaging material between heated jaws, applying adjustable pressure and sealing time, then swiftly separating the jaws within a precise stroke. The instrument measures hot tack strength immediately after sealing, reflecting the real-time adhesion behavior of packaging materials.Q: What types of packaging materials can be tested with the C632M Hot Tack Tester?

A: This equipment is suitable for flexible packaging materials, such as plastic films and composite laminates commonly used in food, pharmaceutical, and consumer goods packaging. It is capable of handling materials within the specimen size range of 100 mm 15 mm.Q: When should the C632M Hot Tack Tester be used in the packaging development process?

A: It is recommended to use the C632M during both research and development phases and routine quality control inspections. The tester verifies that packaging materials meet performance criteria, ensuring seals maintain integrity during thermal processing and handling.Q: Where is the C632M Hot Tack Tester typically installed?

A: Designed as a benchtop instrument, the C632M is commonly installed in quality control laboratories, manufacturing facilities, and research departments of packaging companies. Its compact size and automation facilitate integration into various testing environments.Q: What is the testing process on the C632M Hot Tack Tester?

A: The testing process involves preparing a packaging material specimen, setting the required sealing and testing parameters via the LCD display, placing the specimen between jaws, and initiating the test. The machine performs automatic sealing, jaw separation, and force measurement, with results viewable digitally and exportable via USB or RS232.Q: What are the key benefits of using the C632M Hot Tack Tester for manufacturers and suppliers?

A: Manufacturers and suppliers benefit from the C632M's precise measurement capabilities, compliance with international standards, automatic operation, and user-friendly controls. It helps improve product quality, streamline testing workflows, and ensure consistency in packaging performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Heat Seal and Hot Tack Testers' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese