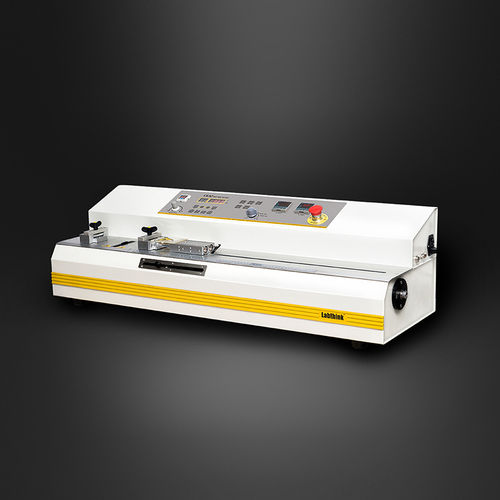

Hot Tack Testing Instrument for Preventing in Flexible Packaging Breakage

50000 USD ($)/Set

Product Details:

- Frequency 50 Hz

- Interface Type USB, RS232

- Port Size 6 mm Pneumatic

- Automation Grade Automatic

- Measuring Range 0.1 - 30 N

- Gas Pressure 0.5 - 0.7 MPa

- Max Height 325 mm

- Click to View more

X

Hot Tack Testing Instrument for Preventing in Flexible Packaging Breakage Price And Quantity

- 50000 USD ($)/Set

- 50000.00 - 100000.00 USD ($)/Set

- 1 Set

Hot Tack Testing Instrument for Preventing in Flexible Packaging Breakage Product Specifications

- 220V AC

- Desktop Testing Device

- 220V, 50 Hz

- 2

- 0.5% F.S.

- Adjustable, 5 - 600 mm/min

- Automatic test cycle, adjustable sealing time, built-in statistical analysis

- 7 digital touch screen

- Laboratory and industrial QC

- 0.01 N

- Approx. 45 kg

- Bench-top

- 0 - 30 N

- Hot tack strength testing in flexible packaging films

- <100 ms

- 30% - 80% RH

- 30 N

- Touch Screen Microprocessor Control

- Up to 15 mm

- Ambient to 250C (Adjustable)

- 325 mm

- 15 x 100 mm

- 0.1 - 30 N

- 0.5 - 0.7 MPa

- 6 mm Pneumatic

- USB, RS232

- Automatic

- 50 Hz

- 250 mm

Product Description

Product FeaturesNote1

Multiple Test Modes in One Instrument

- Four test modes including hot tack, heat seal, peel and tensile test.

- With Digital P.I.D. temperature control system, the preset temperature can be reached in a short time without fluctuations.

- Four force test ranges and 6 testing speeds are available to meet various testing requirements

- The instrument meets the requirement for testing speed specified in standard GB/T 34445-2017

Excellent Designs & Auto Sampling

- Auto sampling for hot tack test, simplifies the testing operation and minimizes errors, ensures the uniformity of test data

- Pneumatic sample clamping system (optional)

- Automatic zeroing, error alert, overload protection and stroke protection guarantee safe operations

- Instrument can be started manually or by pedal switch. it is convenient for the operator and the anti-scald design ensures safe operations

- Components and parts of the instrument are supplied by world renowned manufacturers and have reliable performance

Computer & Instrument Controlled Operations

- Test operations can be performed on the instrument or by the software

- The instrument can be operated without a computer, easy to operate and view test data

- Data I/O ports for data export

Test StandardNote1

GB/T 34445, ASTM F1921, ASTM F2029, QB/T 2358, YBB 00122003

Applications

| Basic Applications |

|---|

|

|

|

|

| Extended Applications |

|

|

|

|

|

|

Technical SpecificationsNote2

| Specification | C632B Hot Tack Tester |

|---|---|

| Load Cell Capacity | 30 N (Standard) 50 N 100 N 200 N (Optional) |

| Force Accuracy | Indicated Value 1% (10%-100% of load cell capacity) 0.1%FS (0%-10% of load cell capacity) |

| Force Resolution | 0.01 N |

| Test Speed | 150 200 300 500 hot tack 1500mm/min, 2000mm/min |

| Specimen Width | 15 mm, 25 mm or 25.4 mm |

| Stroke | 500 mm |

| Heat Seal Temperature | Room Temperature 250C |

| Temperature Variation | 0.2C |

| Temperature Accuracy | 0.5C (Single Point Calibration) |

| Dwell Time (Heat Seal Test) | 0.1 999.9 s |

| Dwell Time (Hot Tack Test) | 0.1 999.9 s |

| Sealing Pressure | 0.05 Mpa 0.7 MPa |

| Sealing Area | 100 mm x 5 mm |

| Sealing Jaws | Double (one is silicon rubber) |

| Gas Supply | Air (Not in supply scope) |

| Gas Supply Pressure | 0.7 Mpa (101.5psi) |

| Port Size | I4 mm PU Tubing |

| Instrument Dimension | 1120 mm (L) 380 mm (W) 330 mm (H) |

| Power Supply | 220VAC10% 50Hz / 120VAC10% 60Hz |

| Net Weight | 45 kg |

Configurations

- Standard Configurations

- Instrument, Manual Clamp, Pedal Switch, Sampling Plate, Calibration Support, I4 mm PU Tubing (2m)

- Optional Parts

- Computer, Professional Software, Pneumatic Sample Grips, Air Compressor

- Note

- 1.The gas supply port of this instrument is I4 mm PU Tubing;

2.Customers need to prepare gas supply.

Note 1: The described test standard, applications and product features should be in line with Technical Specifications.

Note 2: The parameters in the table are measured by professional operators in Labthink laboratory under strictly controlled laboratory conditions.

Advanced Hot Tack Testing Solutions

Designed for modern laboratories and industrial quality control, this Hot Tack Testing Instrument offers automatic test cycles and precise data analysis for flexible packaging films. It supports a wide range of materials, ensuring adaptability to various industrial needs. The equipment's intuitive 7-inch digital touch screen and built-in statistical analysis streamline operations and reporting, making it the top choice for accurate and efficient hot tack strength testing.

Reliable Results for Diverse Materials

Engineered to test BOPP, PET, PE, and laminates, this instrument ensures consistent performance across different packaging films. Adjustable parameters such as sealing time, temperature, and speed allow users to tailor tests to specific material properties. Corrosion-resistant components and pneumatic grips provide durability and stable operation, guaranteeing reliable data for packaging development and quality assurance.

FAQ's of Hot Tack Testing Instrument for Preventing in Flexible Packaging Breakage:

Q: How does the Hot Tack Testing Instrument help prevent flexible packaging breakage?

A: The instrument accurately measures the hot tack strength of packaging films, ensuring the seals are both strong and consistent. By detecting weak seals early, manufacturers can make informed adjustments, ultimately reducing the risk of package breakage during production and distribution.Q: What materials are compatible with this testing equipment?

A: This device is compatible with a range of flexible packaging materials, including BOPP, PET, PE, and various laminates. Its adjustable parameters enable efficient testing across different material types, supporting diverse packaging applications.Q: When should calibration of the Hot Tack Tester be performed?

A: Calibration should be carried out at regular intervals, or when accuracy is questioned. The equipment supports both external and automatic calibration, ensuring that results remain reliable and in compliance with ASTM F1921 and F2029 standards.Q: Where is the optimal location to install and operate the tester?

A: The instrument should be installed on a flat, sturdy bench-top in laboratory or quality control environments. Operating conditions must be within 5C to 40C and 30%-80% RH for accurate performance and to maintain device longevity.Q: What is the process for using the Hot Tack Testing Instrument?

A: After setting parameters like sealing time, temperature, and test speed on the touch screen, load two film specimens into the pneumatic grips. Begin the test to measure the force required to separate the seal, with automatic data storage and analysis facilitated by the device's software and USB/RS232 interfaces.Q: What are the key benefits of using this instrument for your packaging operations?

A: Benefits include precise, repeatable results due to automatic controls and built-in overload protection, customizable testing conditions, and advanced data management. These features help improve product safety, reduce material waste, and streamline the quality assurance process.Q: How is data managed and analyzed with this equipment?

A: The device can store up to 1000 test results, supports PC-based data analysis with included software, and interfaces via USB or RS232 ports. It also provides built-in statistical analysis for thorough review and reporting of test outcomes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packaging Testing Instrument' category

|

LABTHINK INSTRUMENTS CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese